Core definition: Laminated glass is a composite glass product made by permanently bonding two or more pieces of glass together with one or more layers of tough polymer intermediate film (usually PVB, or polyvinyl alcohol butyral) in the middle through high temperature and high pressure process.

1.Safety (anti-breakage and anti-splashing)

This is the most important characteristic of laminated glass. When broken by external force impact, the glass fragments will firmly adhere to the intermediate film and will not splash or fall off in all directions, thus greatly reducing the risk of being cut by glass fragments.

2.Impact resistance and anti-theft property

Laminated glass has excellent impact resistance and is very difficult to be punctured. Even if the glass breaks, the intermediate film can still maintain its integrity. It takes more time and tools to break through, so it has a certain ability to prevent theft and violent intrusion.

3.Sound insulation performance

The polymer membrance in the middle has a damping effect on sound waves and can effectively absorb and reduce the vibration transmission of sound. Especially the laminated glass made of special soundproof PVB film has a better sound insulation effect than ordinary glass and insulating glass.

4.Uv protection

The PVB film in the middle can effectively block over 99% of ultraviolet rays, protecting indoor furniture, carpets, curtains, artworks, etc. from fading due to ultraviolet radiation.

5.Other performance

Durability: Modern laminated glass has stable performance, humidity and high temperature resistance, and is not easy to age and yellow.

Design diversity: It is possible to create colorful interlayers and patterned interlayers (such as sandwiched between silk and plant specimens), which are both aesthetically pleasing and functional.

Lamination: Stake one piece of glass, one layer of PVB film, and another piece of glass in sequence.

Pre-pressing: By means of roller pressing or vacuuming, the air between the glass and the PVB film is initially expelled to form an initial bond.

High temperature and high pressure: The pre-pressed “sandwich” is placed in an autoclave and subject to a specific temperature (typically around 140℃) and pressure (approximately 12-14 atmospheres) fpr several hours. This process cause the PVB film to completely melt and firmly bond with the glass surface, forming a clear and transparent whole.

Due to its outatanding safety, laminated glass is widely used in:

Car windshields (front windshields)–The front windshields of all cars are laminated glass, which is a mandatory standard to ensure that no fragments will fly and hurt passengers in the event of an accident.

Building doors, windows and curtain walls— Especially for high-rise buildings, skylights and glass near sidewalks, to prevent glass from breaking and falling and injuring people.

Railings and stair treads— Provide a transparent view while ensuring safety.

Security places such as banks and jewelry stores— Multi-layer laminated bulletproof glass is used, which is a thickened type of laminated glass.

Observation windows in aquariums and zoos— Capable of withstanding tremendous water pressure and impact.

Photovoltaic modules— Solar panels also adopt a process similar to laminated glass, using EVA or PVB films to encapsulate the solar cells between the glasses.

| Characteristic | Laminated glass | Insulated glass |

| Structure | Glass+Film+Glass | Glass+Dry air/Inert gas+Glass |

| Core function | Safe, anti-theft and UV-resistant | Heat preservation, heat insulation (energy conservation), |

| After breaking | The fragments are stuck to the film and remain intact as a whole | It will break into pieces, but usually the inner and outer layers will not break simultaneously |

| Main applications | Car windshields, sunroofs, railings, curtain walls | Building doors and windows, curtain wall (focus on energy-saving occasions) |

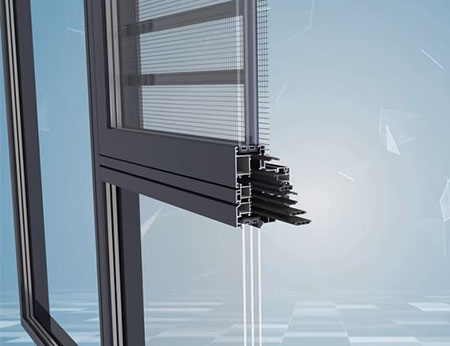

Attention: In order to meet the needs of safety and energy saving at the same time, modern high-end buildings often use “laminated insulating glass”, that is, the combination of laminated glass and insulating glas (for example: laminate glass+insulating glass+ordinary glass).

Laminated glass is a type of safety glass in which multiple layers of glass are permanently bbonded together through a polymer intermediate film. It can maintain its integrity when broken, prevent fragments from flying, and has multiple advantages such as impact resistance, sound insulation and UV protection. It is an indispensable important safety material in daily life.

Methods for distinguishing Indoor and Outdoor Aluminium Doors

Maintenance methods and tips for aluminium doors and windows

Characteristic of outward-opening and hung aluminium windows

Xinhe Aluminium Research: 7.14-7.18 Analysis of Aluminium Prices

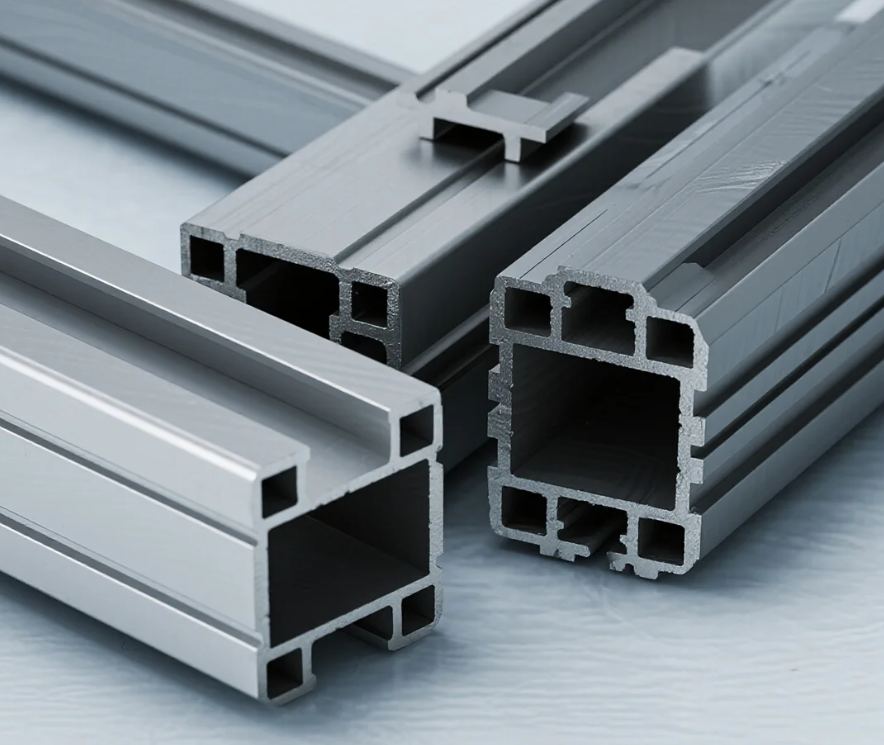

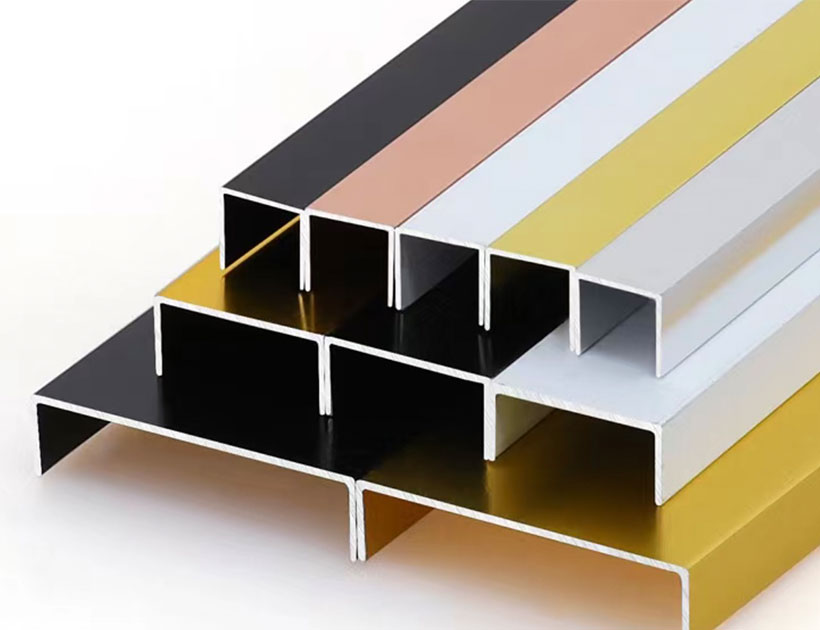

Seven Benefits Of Using Aluminium Profiles In Curtain Wall Systems

The Application of Aluminium Profiles in New Energy Vehicles

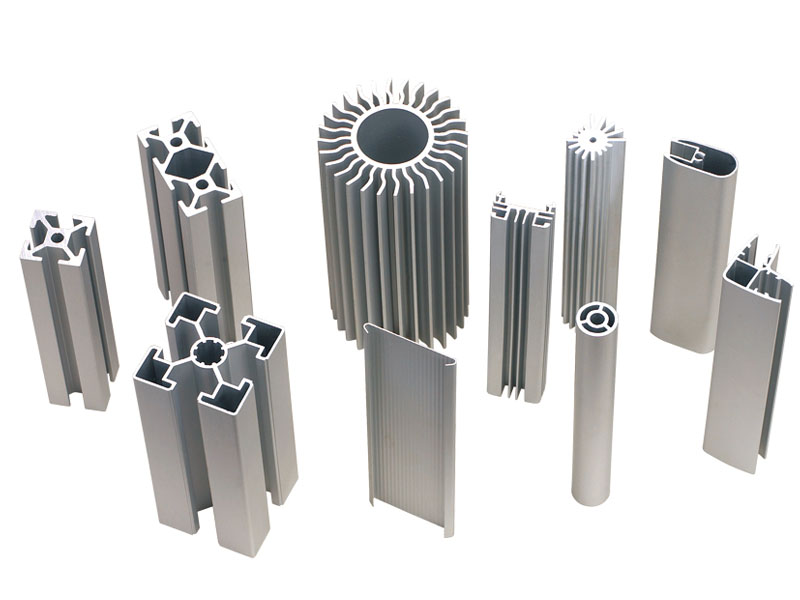

The Composition and Application of Series 6 Aluminium Alloys

Top 5 Benefits of Using LED Aluminium Profiles in Modern Lighting

A Complete Guide to Aluminium Frame Profiles for Modern Structures

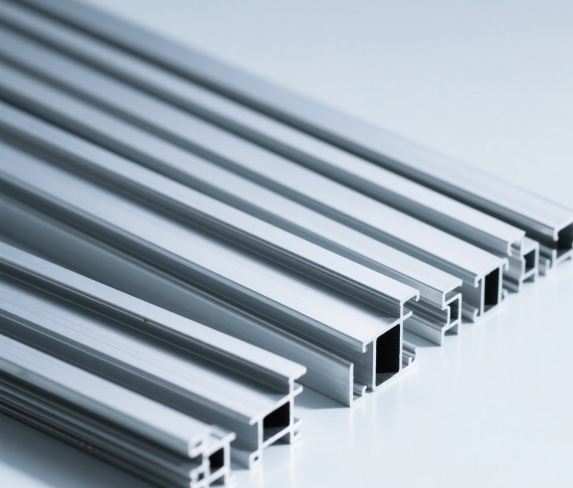

Exploring the Strength and Versatility of Aluminium Extrusion Profiles

How to Choose the Right Aluminium Profile Supplier for Your Project