Thermal break material–Nylon PA66 (containing 25% glass fiber) is adopted, which is heat-resistant, anti-aging and has high strength. (Inferior products may use PVC, which is prone to deformation.)

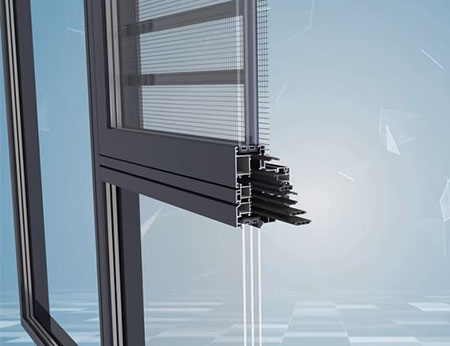

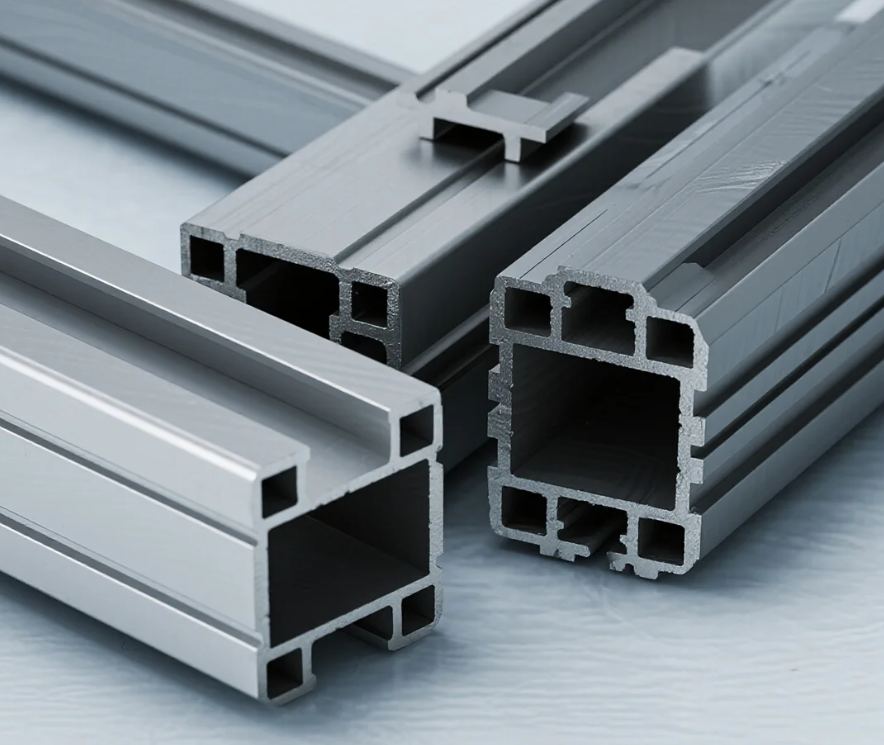

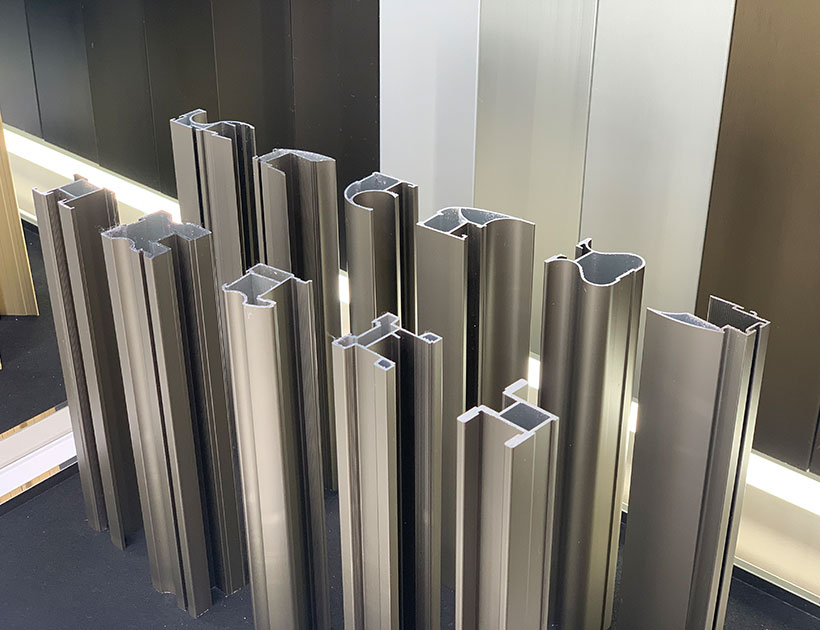

The principle of thermal break–The aluminium profile is divided into two parts, the inner and the outer, and connected by an insulating strip in the middle to block heat conduction (reduce the K value) and decrease the heat exchange between the indoor and outdoor.

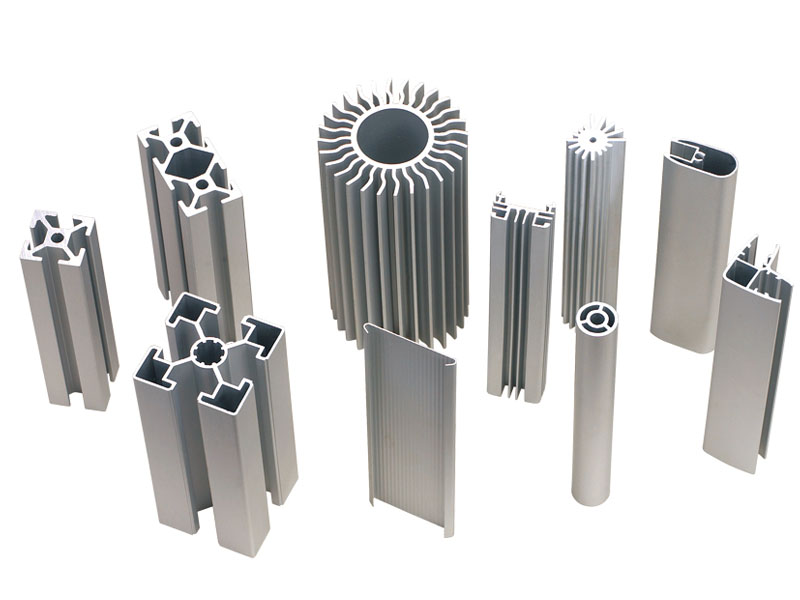

Multi-chamber design–The profile is designed with multiple cavities inside to enhance its sound insulation, heat preservation and wind pressure resistance performance.

Main cavity– Load-bearing structure, enhancing the stability of doors and windows.

Heat insulation cavity–Filled with heat insulation materials.

Drainage cavity–Concealed drainage channel to prevent rainwater from flow backward.

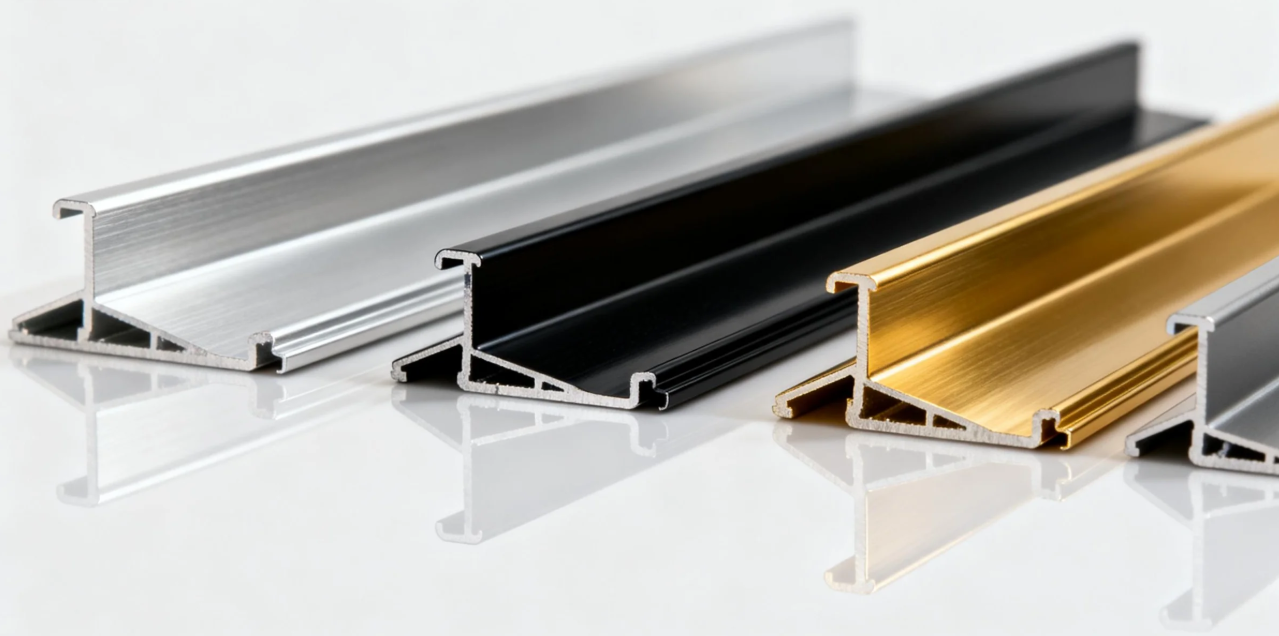

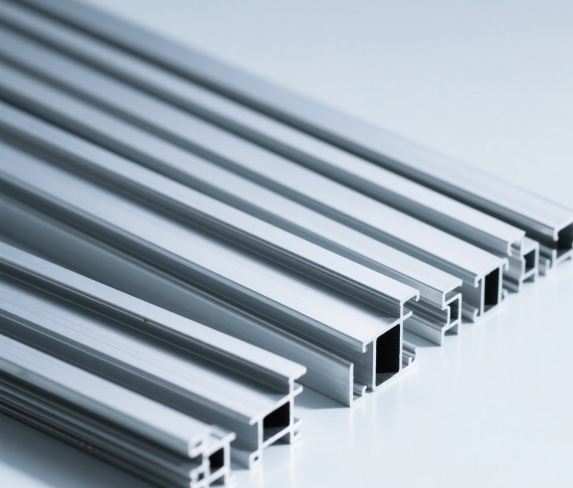

The common 60/70/80/108/120 series (for example, 60 refers to the profile width of 60mm), the larger the value, the better the thermal insulation and soundproofing performance is usually.

Heat insulation and preservation–The thermal break structure reduces heat conduction and keeps warm in winter.

Sound insulation and noise reduction–Multi-chamber+insulating glass (such as 5+20A+5) can reduce noise by 30-40dB (close to professional soundproof windows).

Waterproof and moisture-proof–Three sealing designs (rubber strips+ drainage holes) prevent leakage.

Strong wind pressure resistance– Aluminium profiles have high strength and are suitable for high-rise buildings and coastal areas with strong winds.

Environmentally friendly and durable–Aluminium alloy is corrosion resistant and has a lifespan of 30 to 50 years, far exceeding that of ordinary plastic-steel windows.

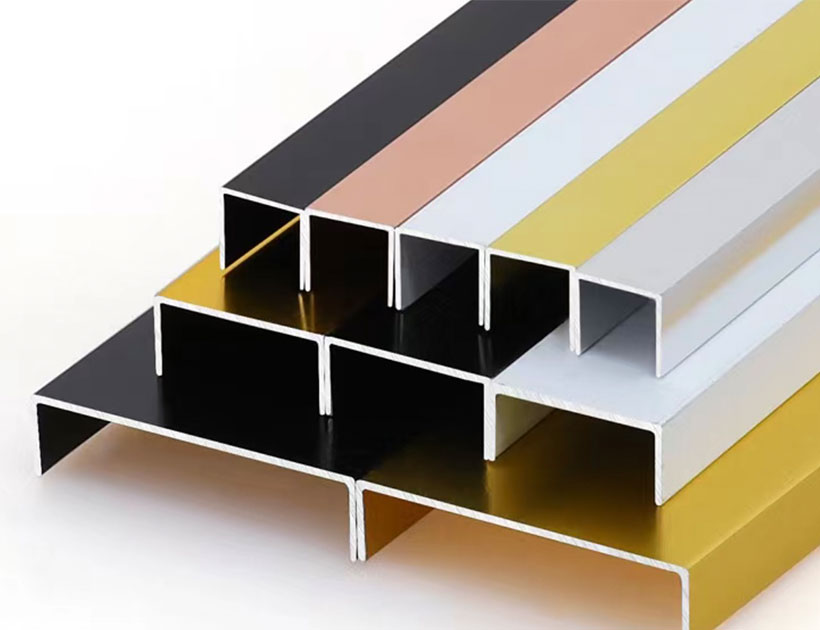

Profiles–Primary aluminium VS Recycled aluminium: Primary aluminium has high strength, while recycled aluminium has many impurities and is prone to deformation.

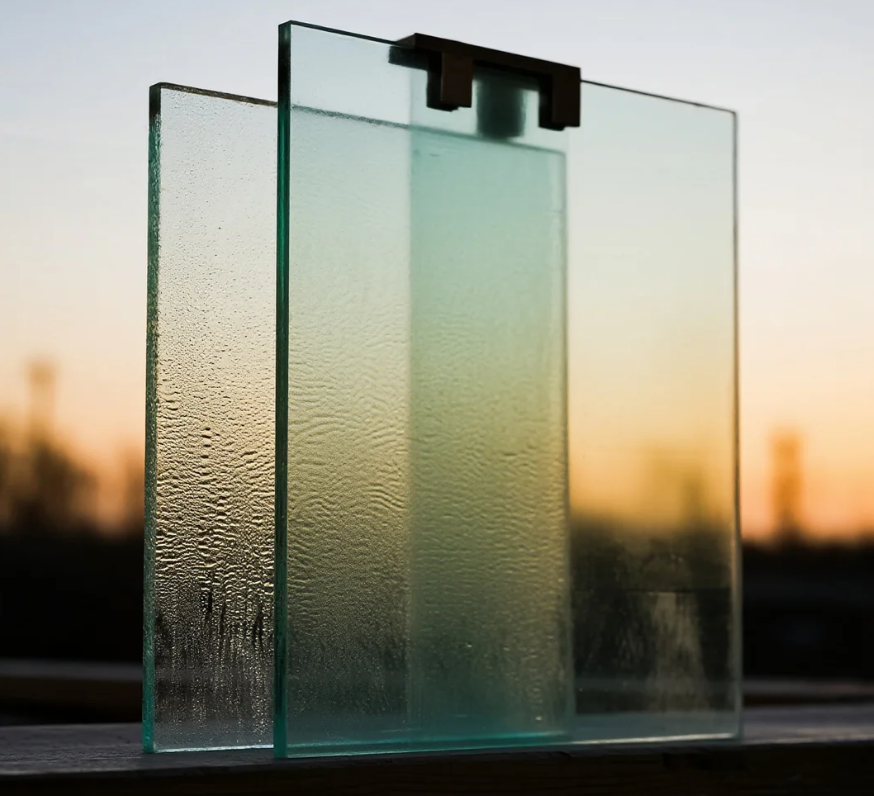

Glass– 1. Hollow glass (such as 5+20A+5): 20A is an argon gas layer, which enhances heat insulation and sound insulation.

2. Low-E glass: Reflect infrared rays, insulate in summer and keep warm in winter.

3. Laminated glass: Explosion-proof and safe, suitable for high-rise building or typhoon areas.

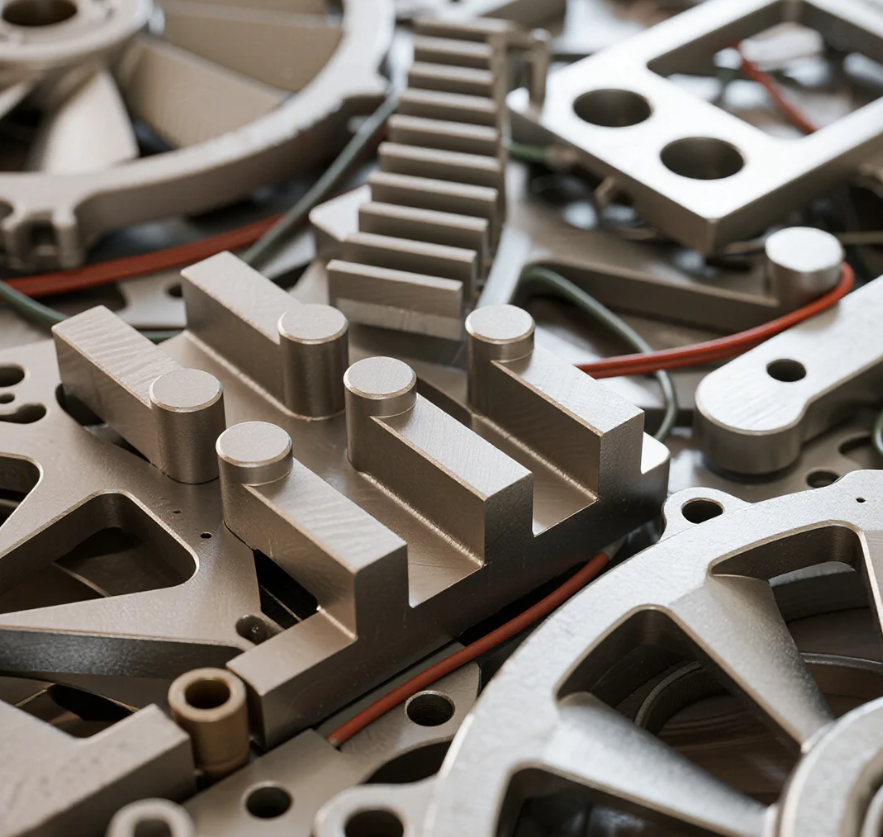

Sealing system– Outer rain-proof rubber strip; Middle constant pressure rubber strip; Inner sound insulation rubber strip.

Drainage design– Hidden drainage holes to avoid water seepage caused by direct blowing.

Q1: What are the difference between thermal break aluminium windows and ordinary aluminium alloy windows?

–Ordinary aluminium windows without thermal insulation strips, conduct heat quickly, cold in winter and hot in summer. Thermal break aluminium windows. The thermal break aluminium alloy blocks heat transfer through PA66 thermal insulation strips.

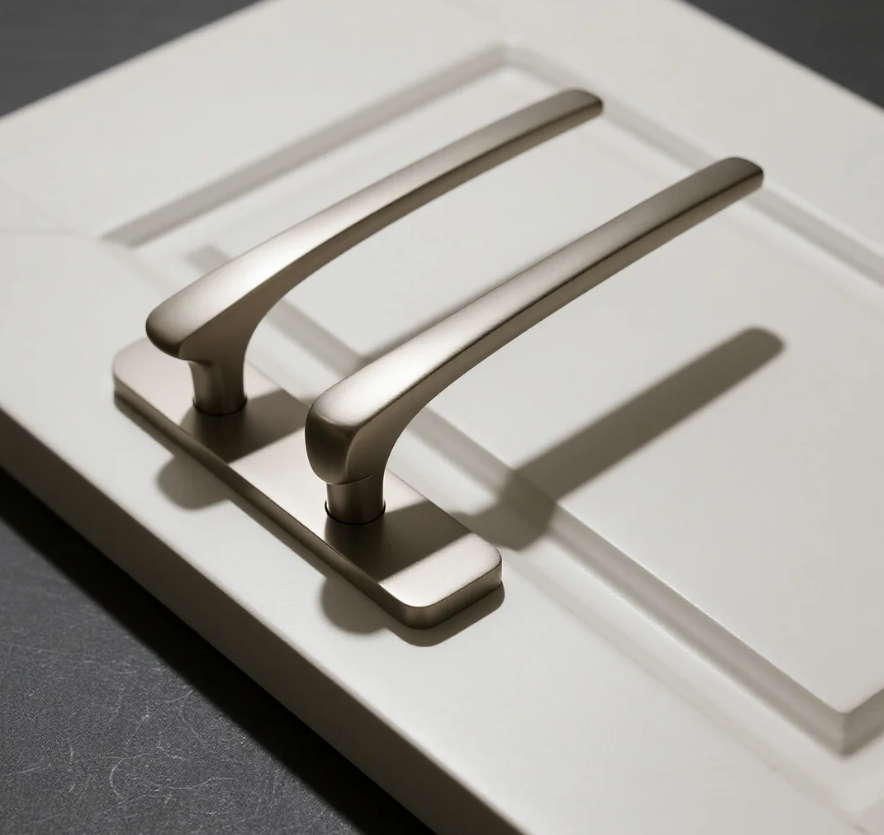

Q2:How to identify inferior thermal break aluminium?

–Look at the cut: The cut of high-quality profiles is bright and free of burrs; Pressure insulation strip: PA66 is not easy to deform, while inferior PVC breaks easily when bent.

Thermal break aluminium doors and windows are the first choice for modern doors and windows that balance energy conservation, safety and durability. When purchasing, pay close attention to the four core components: profiles, glass, hardware and sealing, to avoid low-quality and low-priced products.

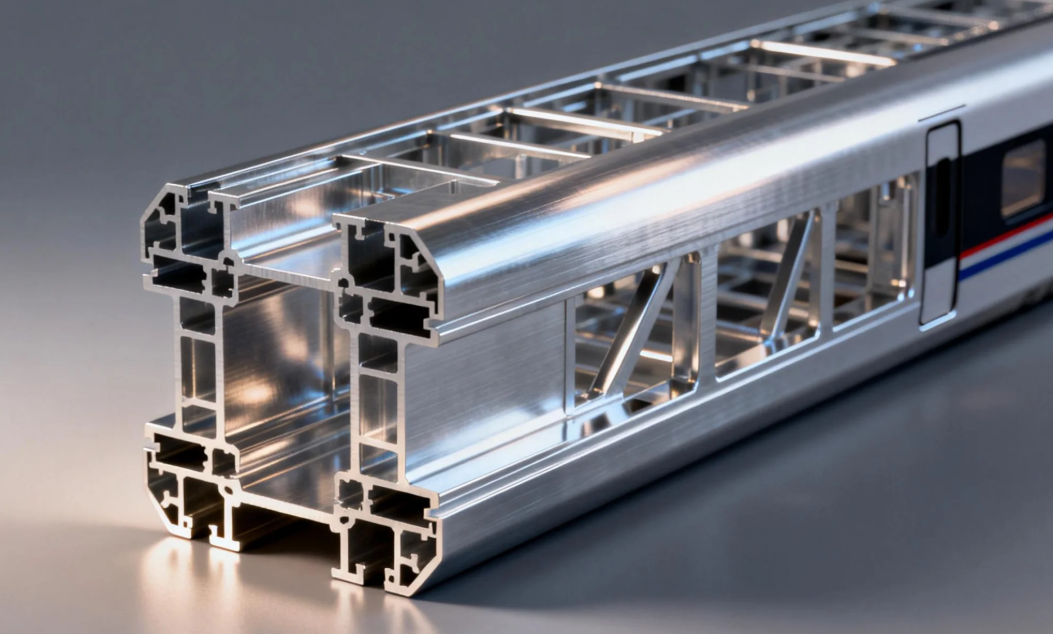

The advantages of using aluminium alloy for the main structure of high-speed train carriages

Methods for distinguishing Indoor and Outdoor Aluminium Doors

Maintenance methods and tips for aluminium doors and windows

Characteristic of outward-opening and hung aluminium windows

Xinhe Aluminium Research: 7.14-7.18 Analysis of Aluminium Prices

Seven Benefits Of Using Aluminium Profiles In Curtain Wall Systems

The Application of Aluminium Profiles in New Energy Vehicles

The Composition and Application of Series 6 Aluminium Alloys

Top 5 Benefits of Using LED Aluminium Profiles in Modern Lighting

A Complete Guide to Aluminium Frame Profiles for Modern Structures

Exploring the Strength and Versatility of Aluminium Extrusion Profiles

How to Choose the Right Aluminium Profile Supplier for Your Project