Breakthrough in the extraction of aluminium: In 1886, Hall of the United States and Héroult of France independently invented the electrolytic aluminium smelting method, making large-scale aluminium production possible and laying the raw material foundation for aluminium profiles.

Early application: In the early days, aluminium was only used in jewelry or luxury goods because of its high price (once as expensive as silver). In the 1890s, aluminium began to be used in small amounts for architectural decoration (such as the domes of Parisian churches).

World War I promoted development: During World War I(1914-1918), aluminium was used in aircraft components because of its lightweight properties, giving rise to the demand for simple extruded aluminium profiles.

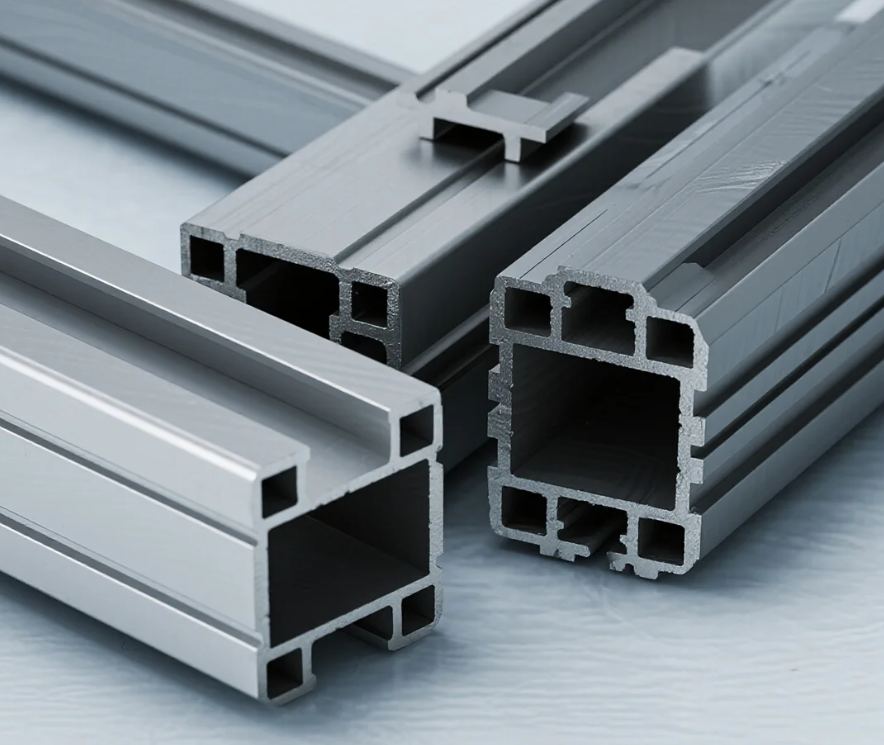

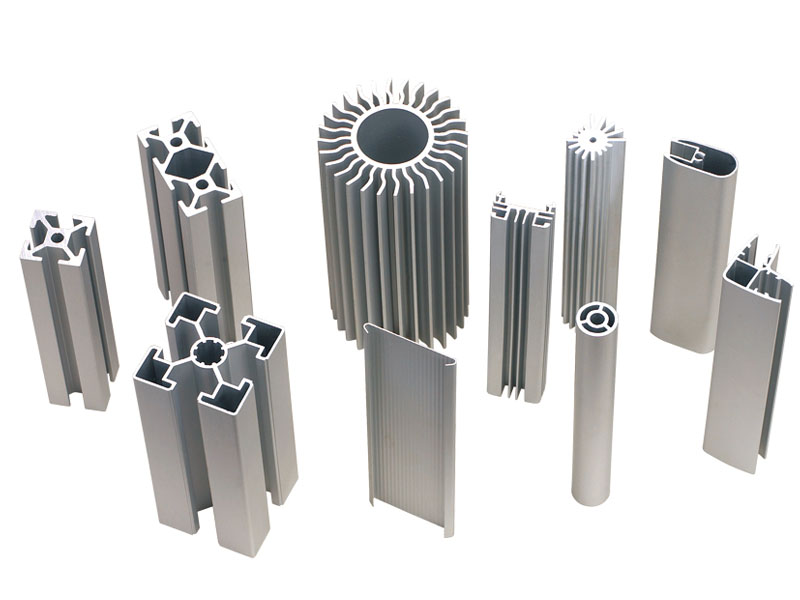

The emergence of extrusion technology: In the 1920s, Germany and the United States developed mechanical extruders that could produce aluminium profiles with simple cross-sections, but they were inefficient.

Military demands during World War II: During World War II (1939-1945), aluminium profiles were widely used in aircraft and ship structures, promoting the advancement of high-strength alloys (such as 2024,7075) and extrusion processes.

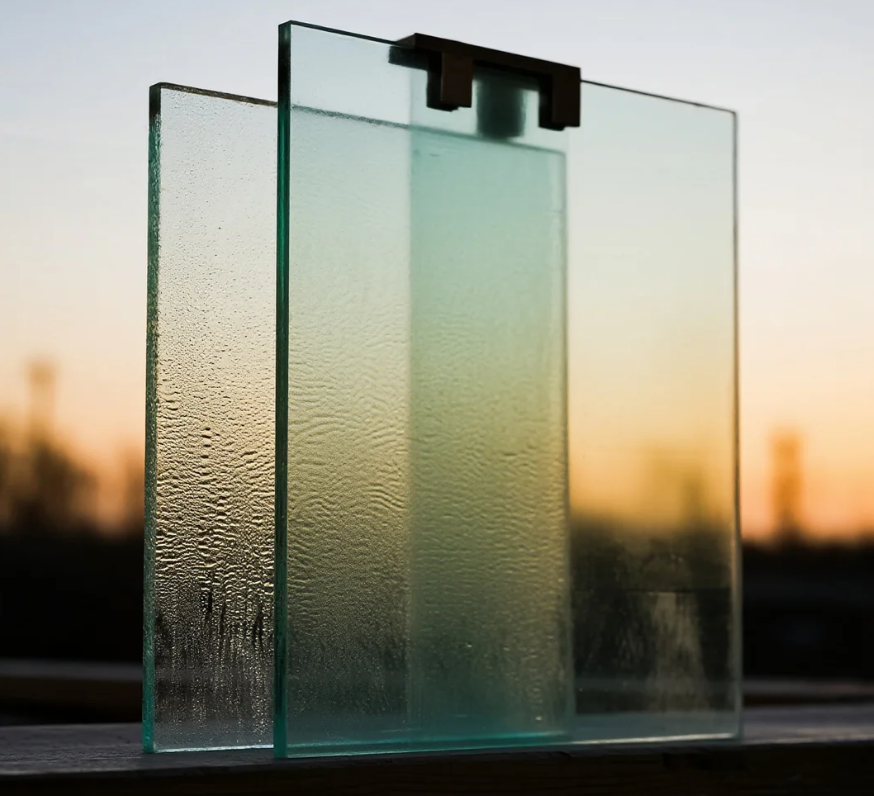

Civilian transformation: After the war, there was an excess of aluminium production capacity, and it shifted to civilian use. In the 1950s, American companies such as ALCOA developed window and door profiles for buildings, and aluminium curtain walls began to gain popularity (such as in the United Nations Headquarters building in New York).

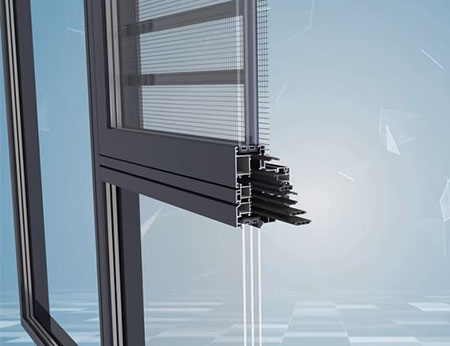

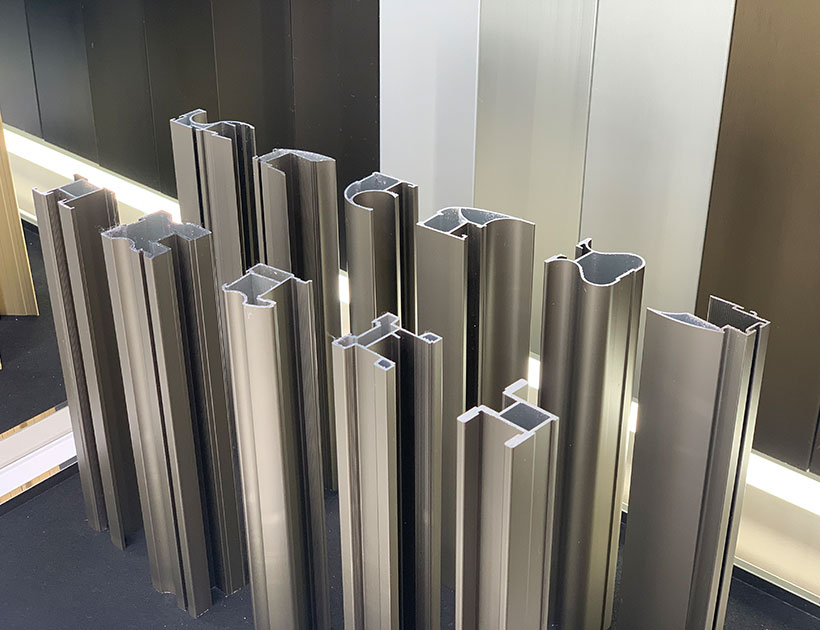

Architectural Revolution: In the 1960s, aluminium alloy doors, windows and curtain walls became the symbols of modern architecture. Japan and Europe formulated profiles standards (such as the European standard EN 755).

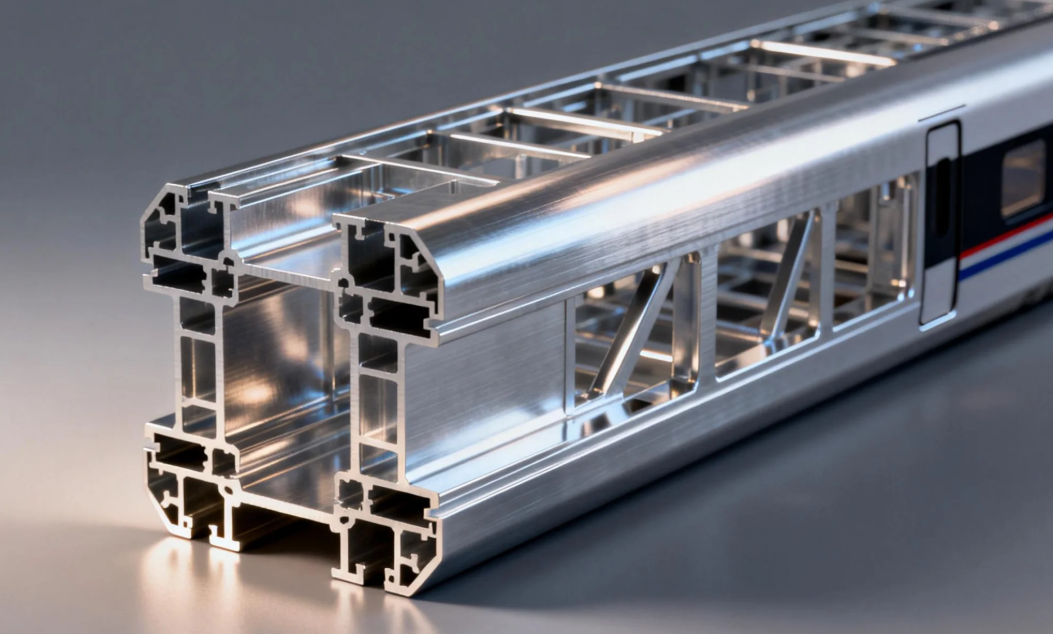

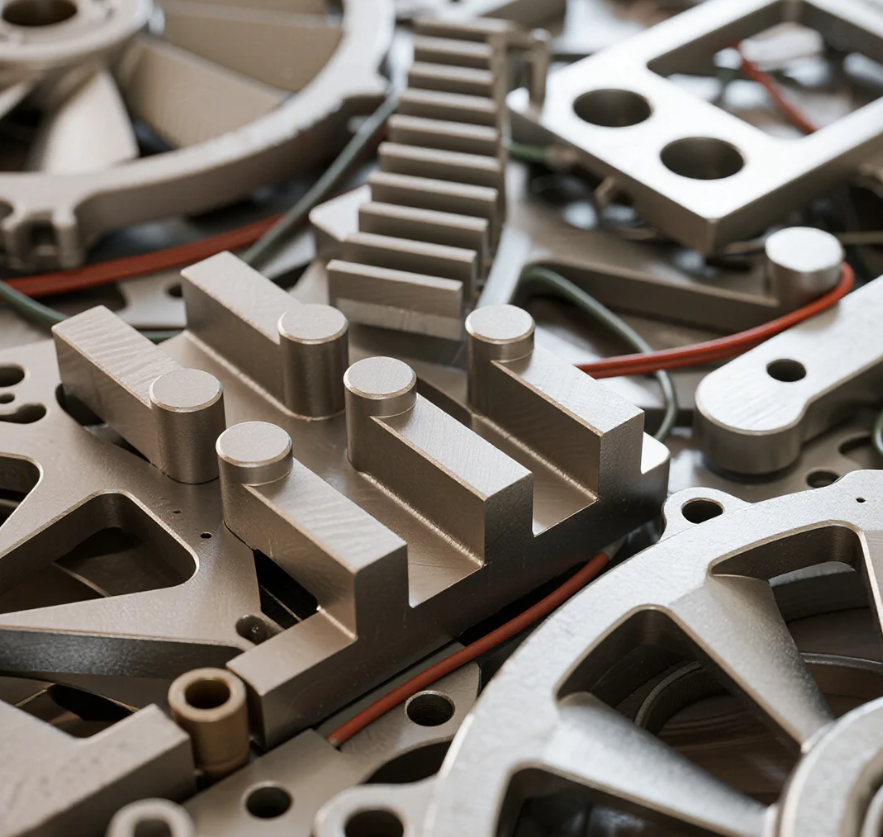

Industrial application expansion: Customized aluminium profiles are adopted in fields such as transportation (train carriages, auto parts) and electronics (radiators).

China’s start: In the 1970s, China established its first batch of aluminium profile factories, but the technology lagged behind Europe and America.

The rise of China: After 1990, China became the world’s largest producer of aluminium profiles, and many aluminium profile enterprises rapidly expanded by introducing equipment from Europe and America.

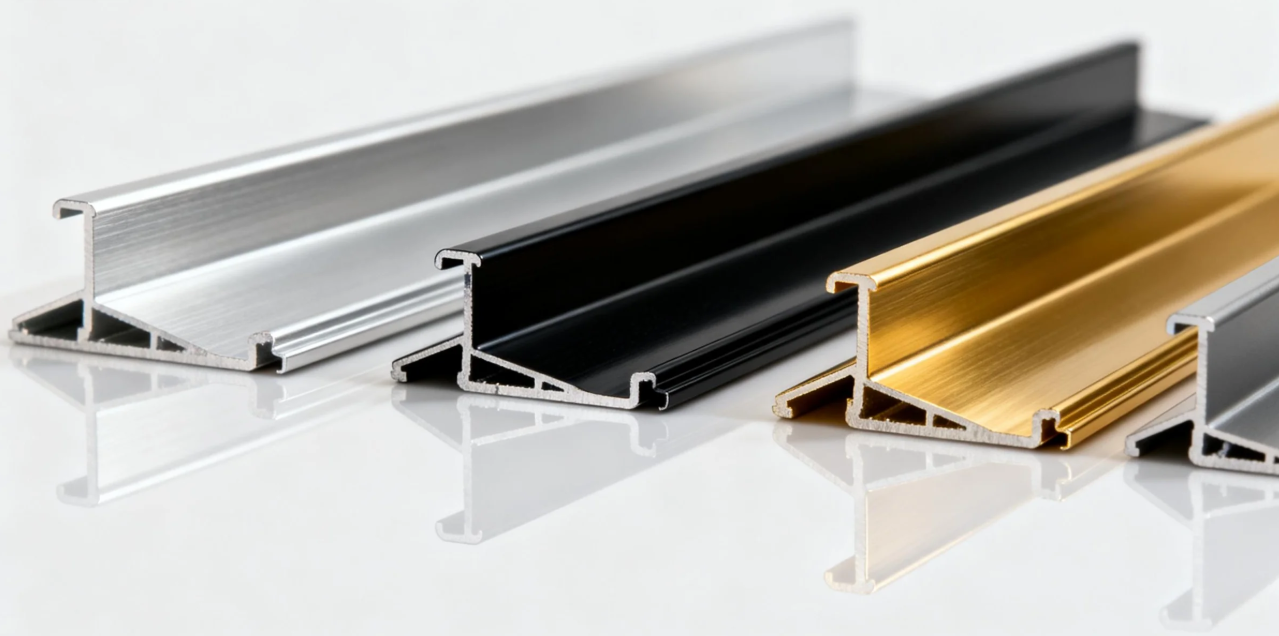

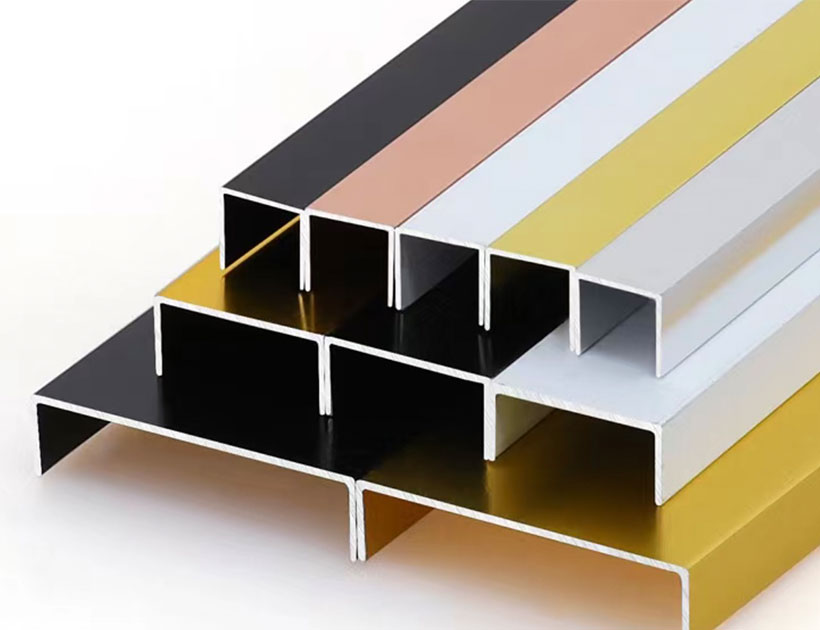

Technological upgrade: Isothermal extrusion and CAD design of molds to enhance precision; Surface treatment technologies (fluorocarbaon spraying, electrophoresis) extend the service life.

New energy application: In the 2010s, the photovoltaic industry drove the demand for aluminium profile brackets, and automotive lightweighting (the all-aluminium body of Tesla Model S) became a new growth point.

Green manufacturing: The proportion of recycled aluminium profiles has increased (for instance, Novelis’ global recycling rate exceeds 50%), and low-carbon electrolytic aluminium (hydroelectric aluminium) is highly sought after.

High-end applications: New energy battery trays and complex structural components in aerospace rely on special aluminium profiles (such as 3D printing+extrusion composite process)

Digital production: AI quality inspection, Internet of Things device monitoring to optimize yield rates, leading enterprises establish “dark factories”

Material innovation: Nano- modified aluminium profiles, aluminium matrix composites.

Cross-industry integration: Potential applications of aluminium profiles in hydrogen energy storage and transportation, and space capsule structures.

Regional supply chain: Under geopolitical circumstances, Europe and the United States are promoting the reconstruction of domestic aluminium profile production capacity.

The advantages of using aluminium alloy for the main structure of high-speed train carriages

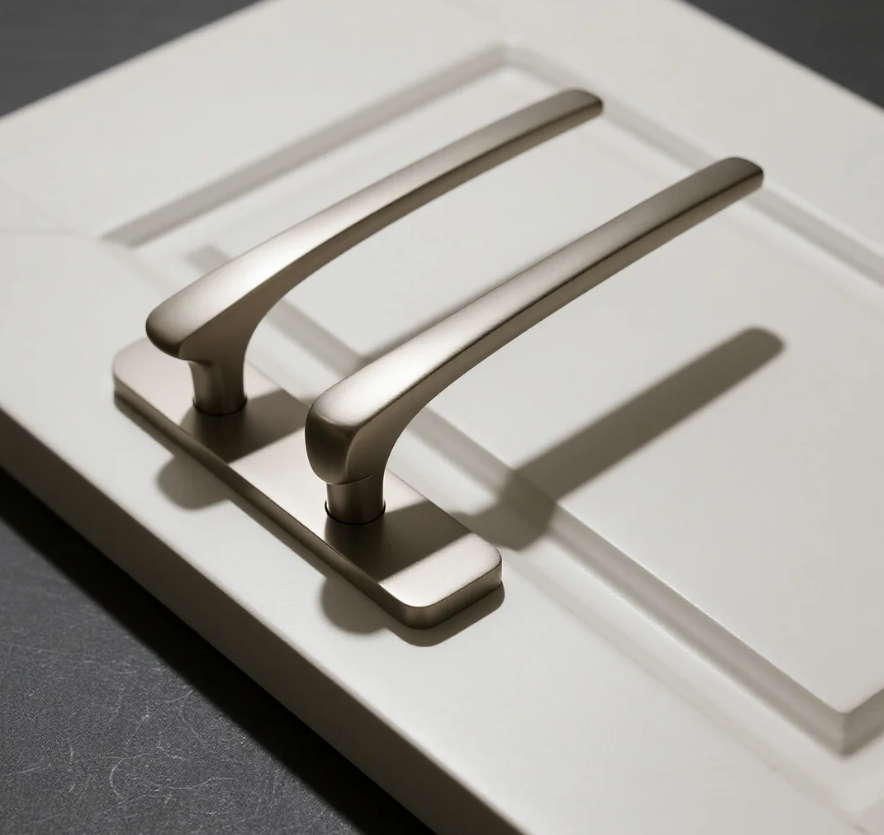

Methods for distinguishing Indoor and Outdoor Aluminium Doors

Maintenance methods and tips for aluminium doors and windows

Characteristic of outward-opening and hung aluminium windows

Xinhe Aluminium Research: 7.14-7.18 Analysis of Aluminium Prices

Seven Benefits Of Using Aluminium Profiles In Curtain Wall Systems

The Application of Aluminium Profiles in New Energy Vehicles

The Composition and Application of Series 6 Aluminium Alloys

Top 5 Benefits of Using LED Aluminium Profiles in Modern Lighting

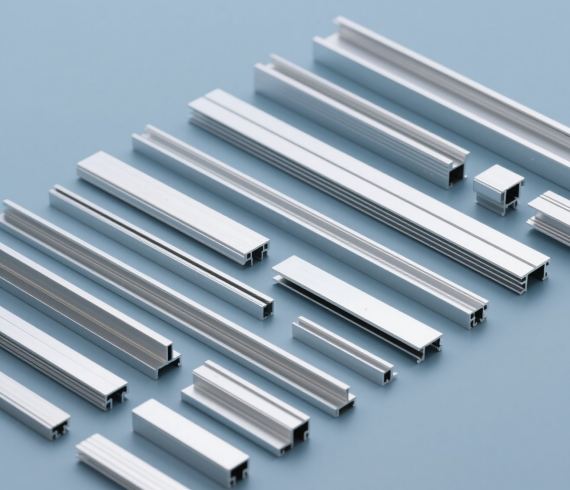

A Complete Guide to Aluminium Frame Profiles for Modern Structures

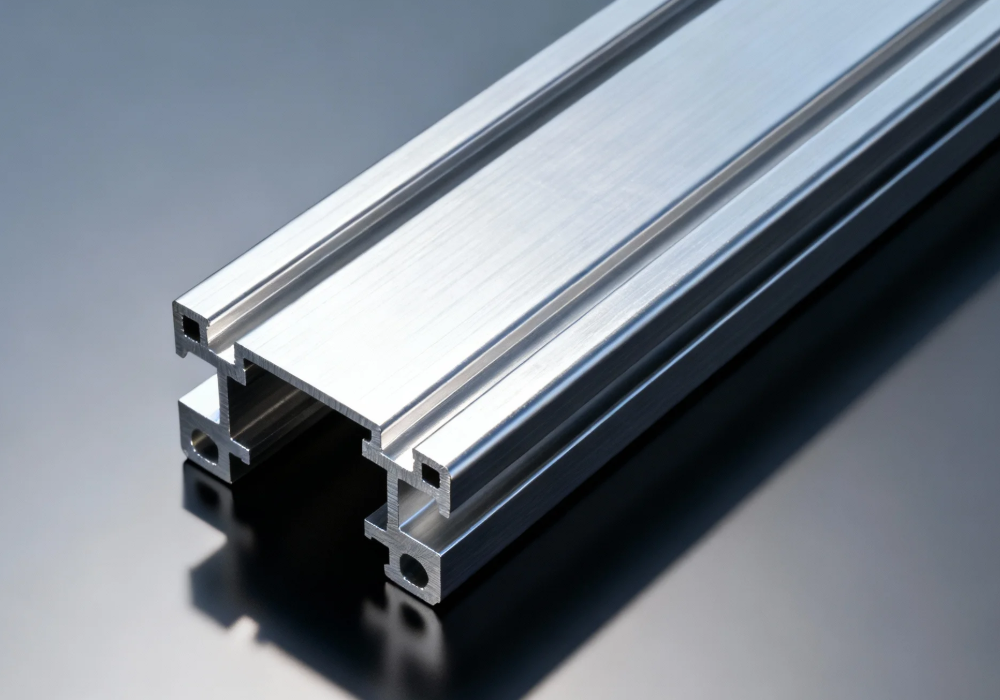

Exploring the Strength and Versatility of Aluminium Extrusion Profiles

How to Choose the Right Aluminium Profile Supplier for Your Project