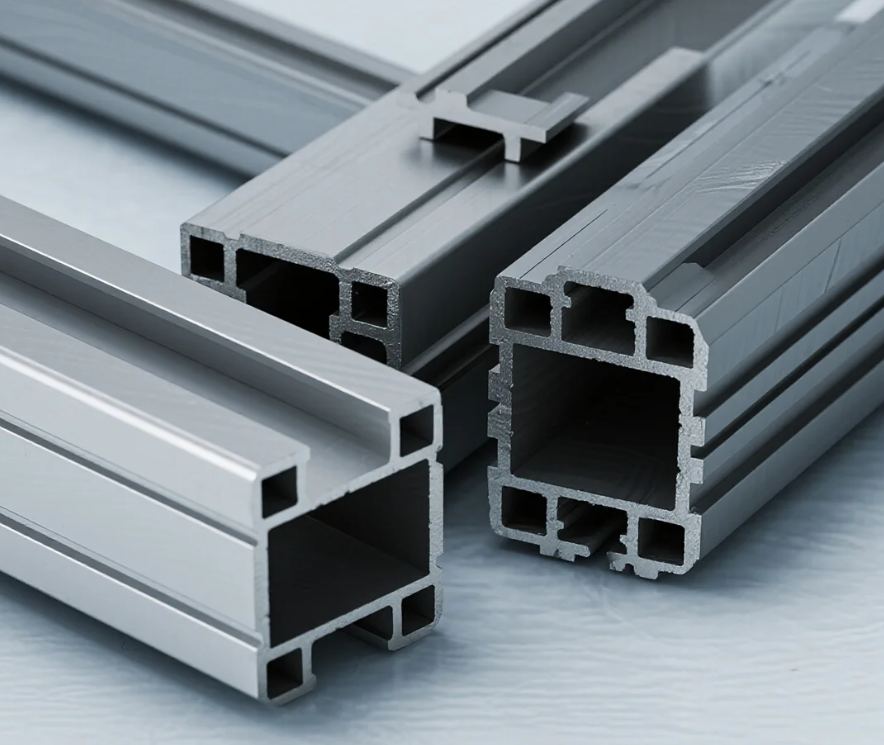

The use of aluminium sunroom frame is the mainstream and high-end choice in modern sunroom construction. Compared with traditional steel, wood or plastic steel, it has a series of incomparable comprehensive advantages. The following is a detailed analysis of the benefits.

Core advantages in structural performance and durability

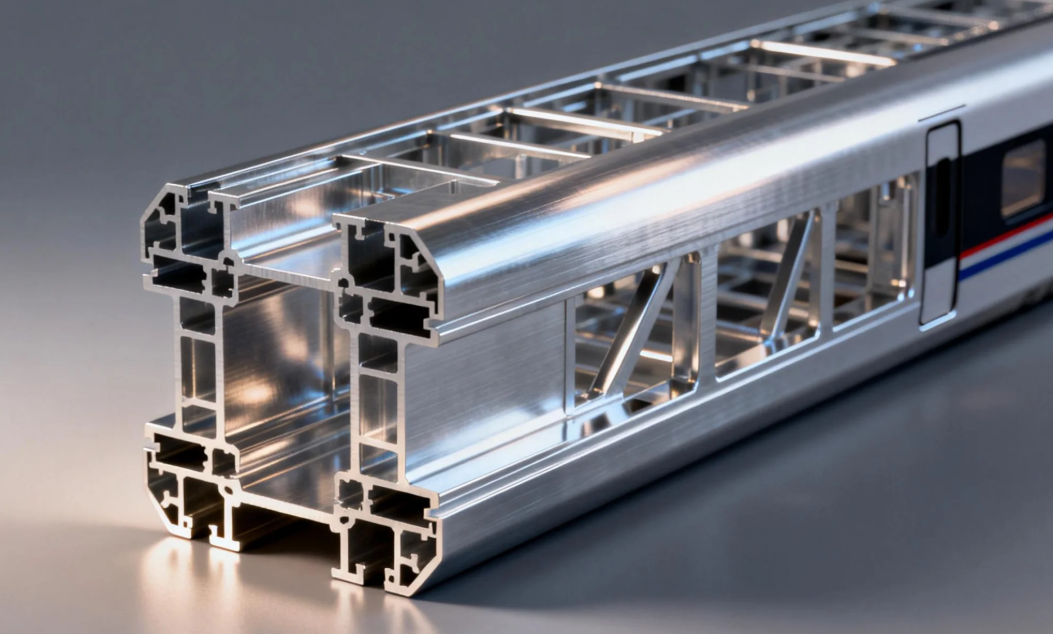

Outstanding strength and stability

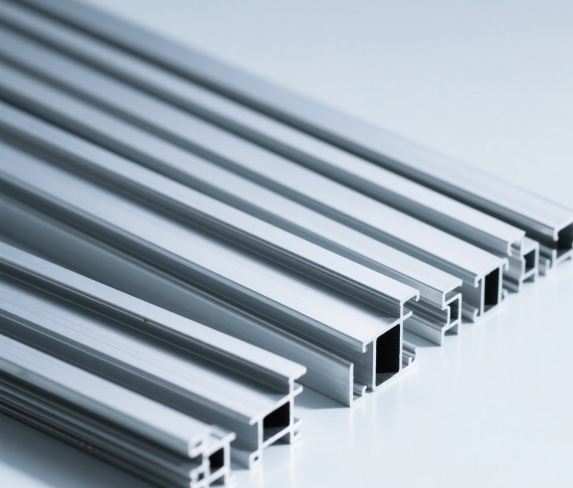

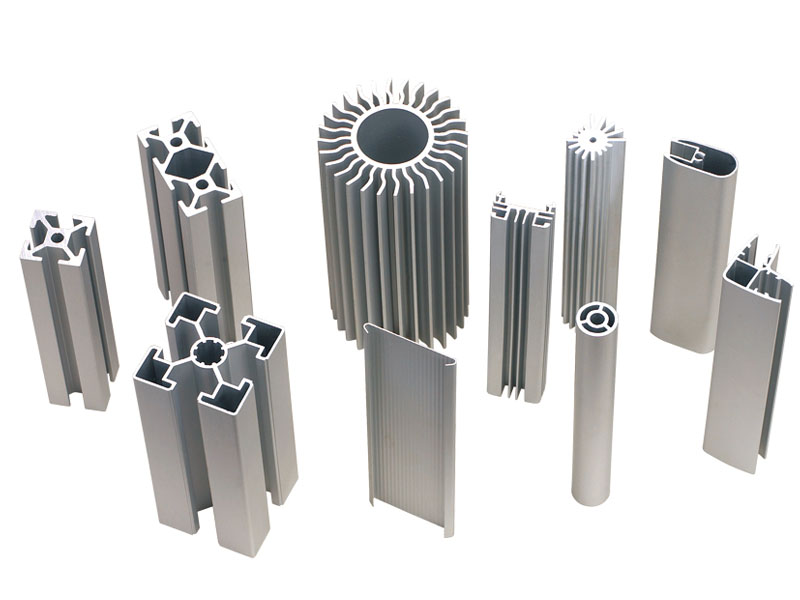

It adopts high-strength aluminium alloy profiles (such as 6061, 6063-T5/T6 states), and through scientific cross-sectional design and structural reinforcement, it can withstand huge wind pressure, snow load and self-load. The properties of metals determine that they hardly deform, crack or shrink, and can maintain structural stability for a long time, ensuring the sealing performance of doors and windows.

Unparalleled corrosion resistance

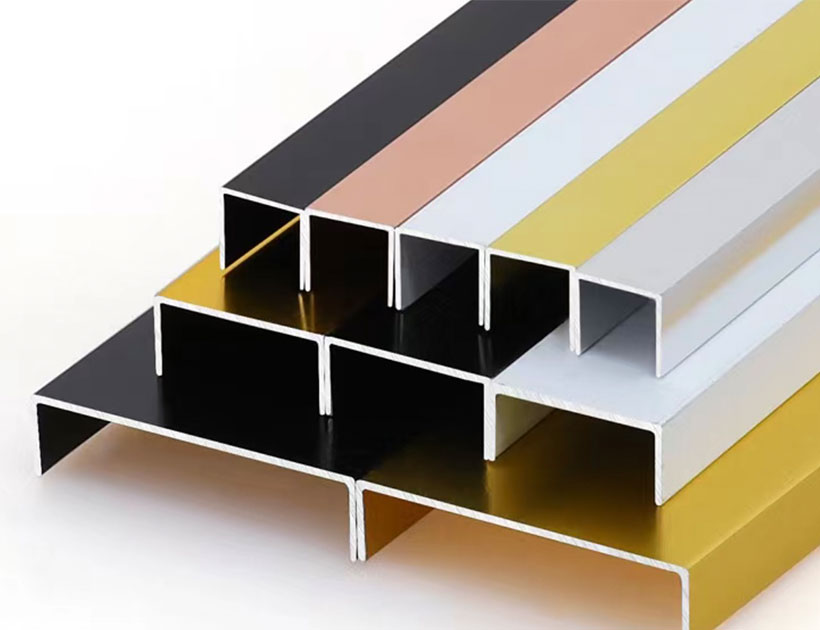

This is the greatest advantage of aluminium over steel. The natural oxide layer on the aluminium surface and subsequent advanced surface treatments (such as anodizing and fluorocarbon spraying) endow it with an extremely strong anti-rust ability. It can perfectly resist harsh weather conditions such as sun exposure, rain and humidity, and will never be troubled by rust for life. It is particularly suitable for outdoor environments.

Extremely long service life

Under normal use and maintenance, the service life of high-quality aluminium sunroom frames can reach over 50 years, far exceeding that of plastic steel and wood, and is in line with the lifespan of the main building.

Design aesthetics and flexibility advantages

Slender and beautiful with a wide field of vision

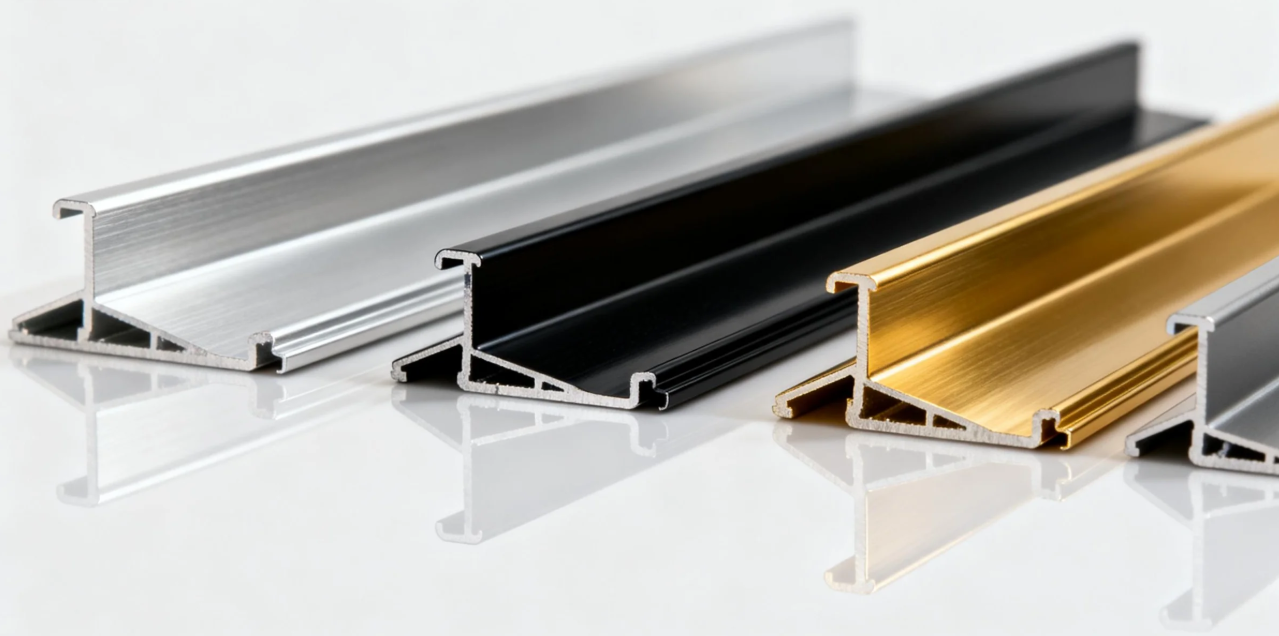

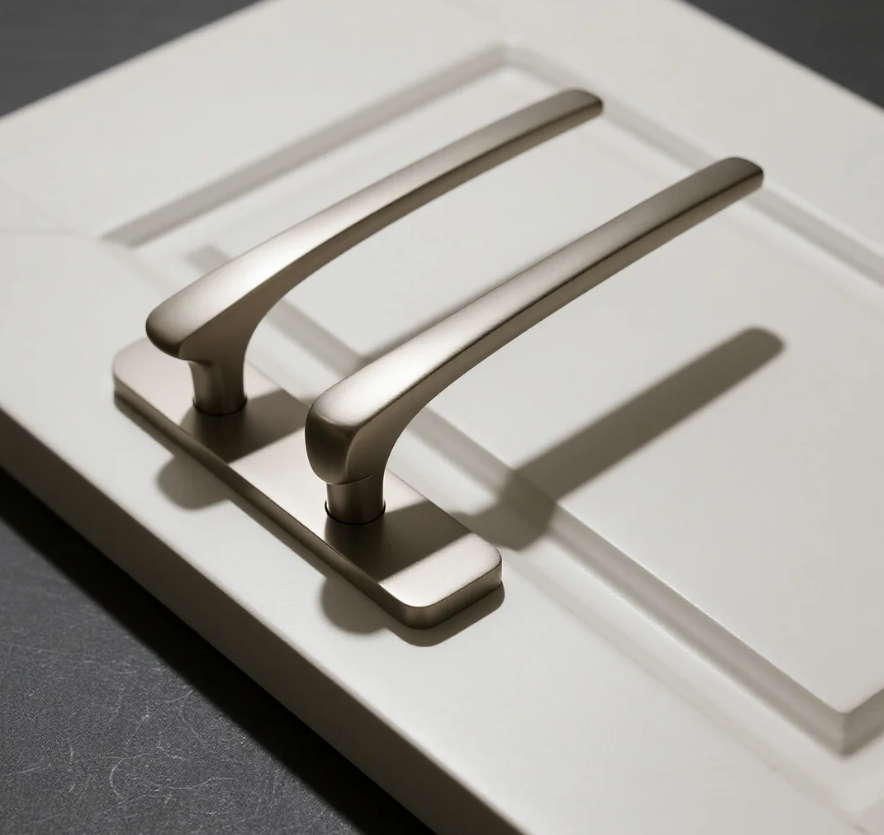

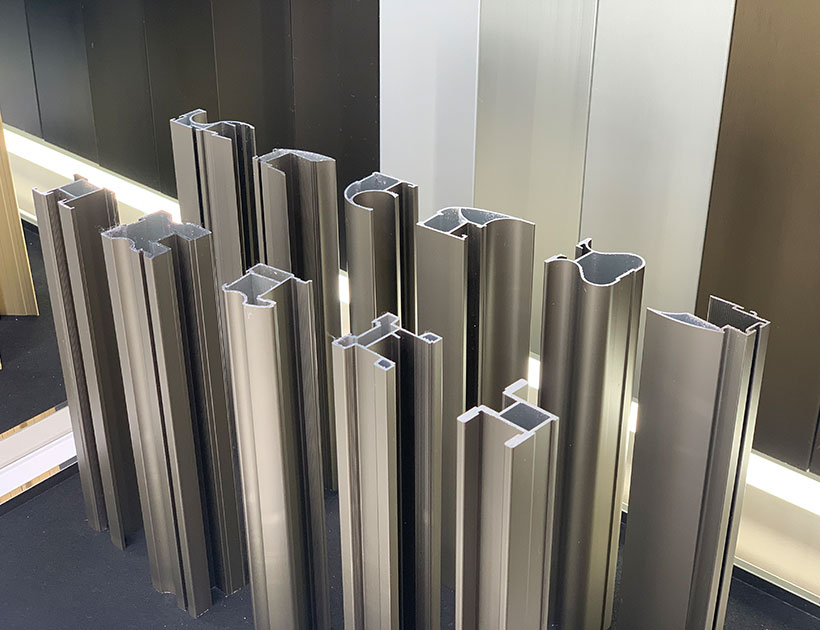

Aluminium profiles can achieve extremely narrow frame designs (thanks to high strength), significantly reducing visual obstruction, maximizing the glass area and the field of vision for light transmission, and have a strong modern feel. The surface treatment features a rich variety of colors (metallic, wood-grain imitaion, and various custom colors), which can blend perfectly with any architectural style.

Strong styling ability

The excellent extrusion forming characteristics of aluminium alloy can produce complex and smooth special-shaped materials, easily achieving various personalized designs such as arcs, inclined tops, and multi-angle combinations, meeting the demands of creative shapes.

Advantages in sealing and energy conservation and environmental protection

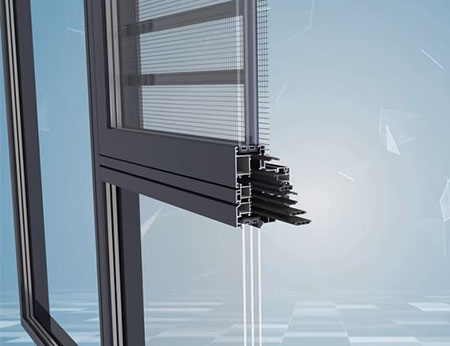

Outstanding sealing performance

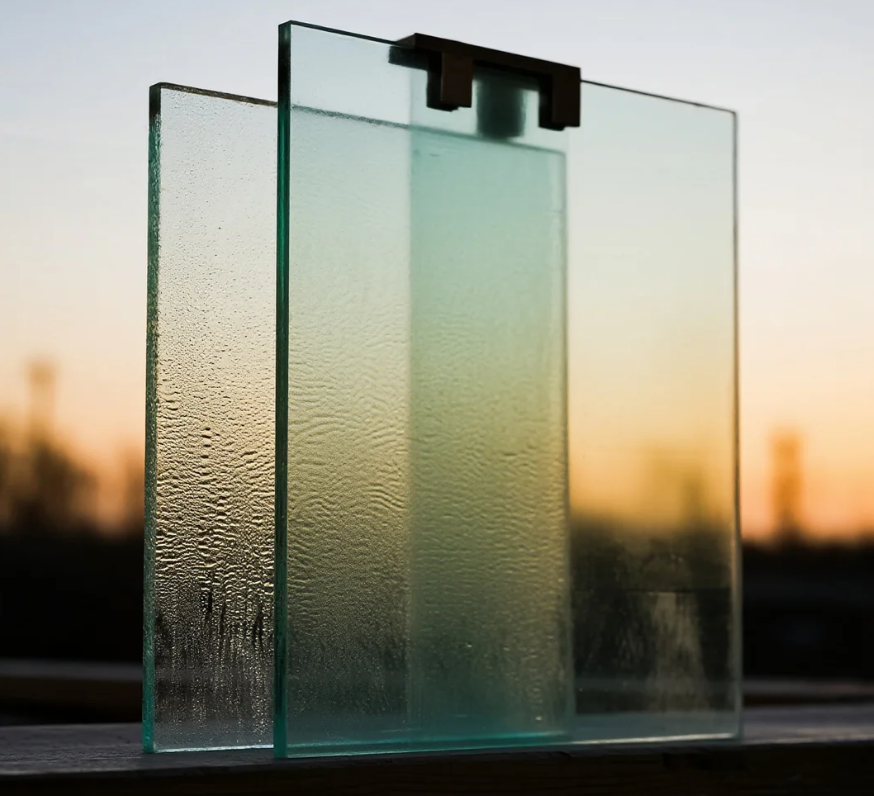

The aluminium alloy frame is equipped with high-quality automotive-grade sealing strips (such as EPDM) and adopts a multi-seal design to achieve excellent water tightness, air tightness and sound insulation.

Outstanding heat insulation performance (Key breakthrough)

The adoption of “broken bridge aluminium” technology is the core highlight. High-strength thermal break strips (PA66 GF25) are injected in the middle of the aluminium profiles to physically separate the inner and outer aluminium frames, effectively blocking heat conduction.When combined with hollow Low-E glass, its heat insulation performance (K value) can rival or even exceed that of high-quality plastic-steel windows, solving the pain point of traditional aluminium alloys not being heat-insulating, achieving warmth in winter and coolness in summer, as well as energy conservation and consumption reduction.

Environmental protection and health

Aluminium itself is non-toxic and its surface treatment is safe. 100% recyclable and reusable, the production and usage processes are environmentally friendly, in line with the concept of green buildings.

Advantages in usage and maintenance

Extremely low maintenance costs

True “maintenance-free”: Unlike wooden structures that require regular painting for anti-corrosion, there is no need to worry about rusting like steel structures. It only requires simple wiping and cleaning on a daily basis.

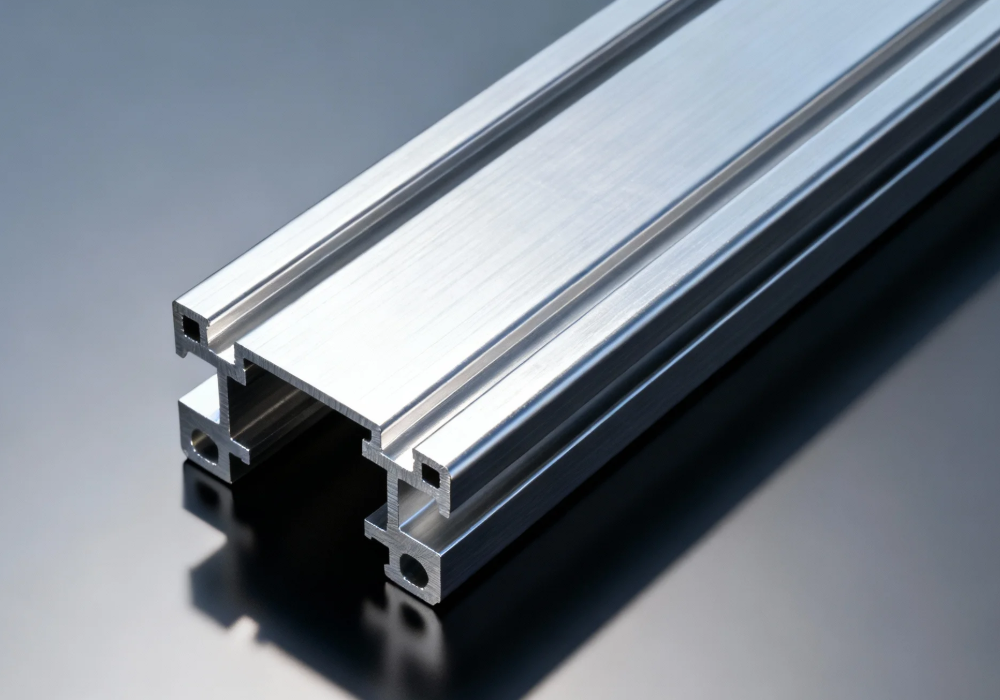

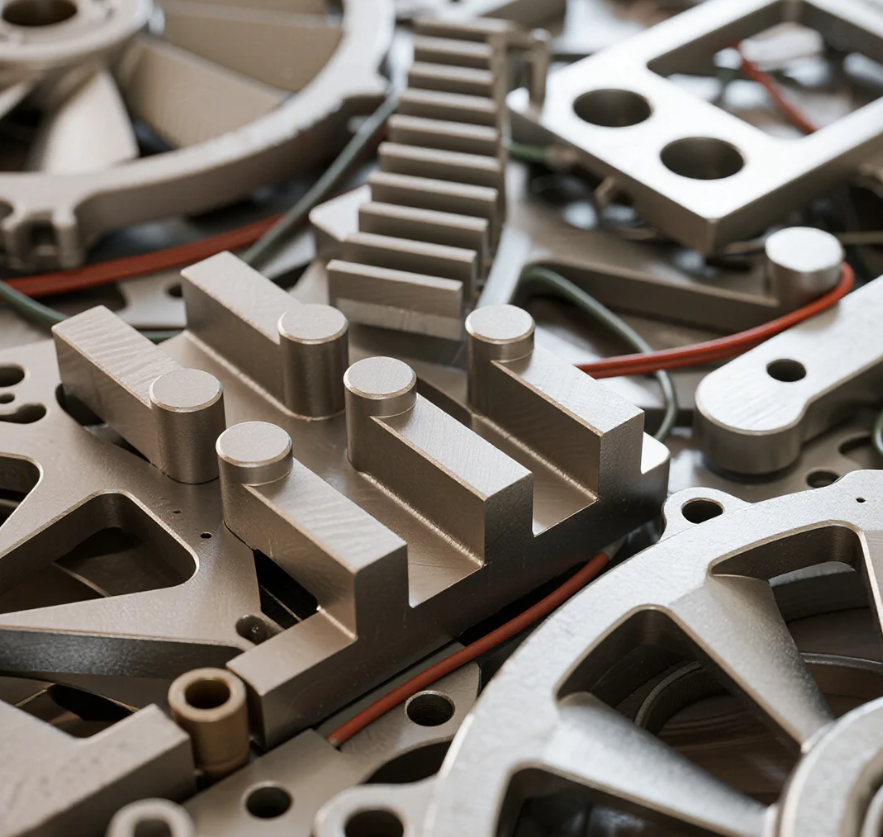

High precision and modular installation

Factory precision processing, on-site assembly, fast, clean and highly standardized construction, which can effectively guarantee the overall quality and construction period.

A comparison with traditional frame materials

| Characteristics | Aluminium frame (especially broken bridge aluminium) | Steel frame | Wooden frame | PVC frame |

| Strength/Durability | Extremely high, no deformation | High, but easy to rust | It is easy to deform and crack under moisture | Generally easy to aging deformation |

| Corrosion resistance | Excellent | Poor, need frequent maintenance | Poor, need paint maintenance | Good |

| Thermal insulation | Thermal break is excellent | Bad | Good | Good |

| Aesthetics/Vision | Extremely narrow bezel | The border is relatively thick | It’s naturally warm, but there’s a lot of shade | The border is rather thick and the texture is general |

| Service life | More than 50 years | Depends on rust prevention maintenance | 10-20 years, need careful maintenance | It is prone to discoloration and aging after 15 to 25 years |

| Maintenance cost | Extremely low | High | High | Lower |

| Design flexibility | Extremely high | General | Higher | General |

| Environmental friendliness | High and fully recyclable | Recyclable | Renewable, but requires felling | Recycling is difficult, including PVC |

Conclusions and suggestions

Aluminium sunroom frames, especially the “thermal break aluminium system”, represent the best solution for current sunroom structures. It successfully strikes a balance between structural strength and lightweight, modern aesthetics and functional practicality, long-lasting durability and energy-saving comfort, as well as one-time investment and lifetime maintenance-free.

Suggestion: If you plan to build a sunroom, especially when you are pursuing long service life, low maintenance, high appearance level, good thermal comfort and long-term investment return, high-quality broken bridge aluminium frame is undoubtedly the first choice.

The advantages of using aluminium alloy for the main structure of high-speed train carriages

Methods for distinguishing Indoor and Outdoor Aluminium Doors

Maintenance methods and tips for aluminium doors and windows

Characteristic of outward-opening and hung aluminium windows

Xinhe Aluminium Research: 7.14-7.18 Analysis of Aluminium Prices

Seven Benefits Of Using Aluminium Profiles In Curtain Wall Systems

The Application of Aluminium Profiles in New Energy Vehicles

The Composition and Application of Series 6 Aluminium Alloys

Top 5 Benefits of Using LED Aluminium Profiles in Modern Lighting

A Complete Guide to Aluminium Frame Profiles for Modern Structures

Exploring the Strength and Versatility of Aluminium Extrusion Profiles

How to Choose the Right Aluminium Profile Supplier for Your Project