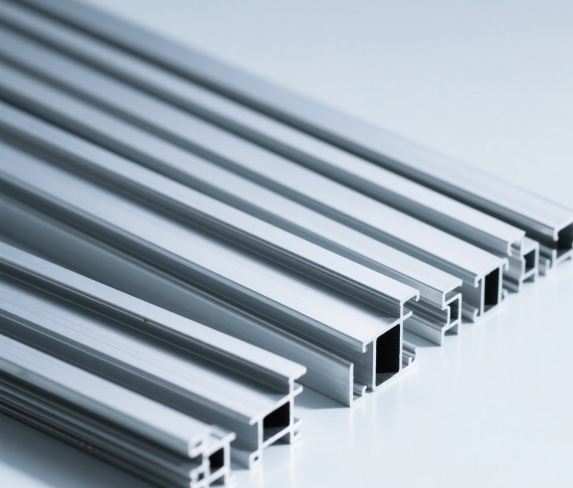

Aluminium profiles are one of the most mainstream and cost-effective materials for manufacturing heat sinks, which is attributed to a series of excellent physical and processing properties of aluminium. The following are the main benefits of using aluminium profiles for heat sinks:

This is the most crucial performance indicator of the hear sink. The thermal conductivity of aluminium is approximately 200-240W/(mk). Although it is not as copper (about 400 W/(m`k), it is much higher than many other metals and materials. This heat conduction capacity is sufficient to effectively and rapidly conduct heat from the heat source (such as CPU/LED chips, power devices) to the various fins of the heat sink for dissipation.

The density of aluminium is very low (about 2.7g/㎤), approximately one-third that of copper (8.9g/㎤). This makes the aluminium heat sink very lightweight. This makes the aluminium heat sink very lightweight. This is crucial for modern electronic devices, especially in– Consumer electronics such as laptops and smart phone are extremely sensitive to weight; Aerospace transportation: Reducing every gram of weight can save fuel or improve performance; Large-scale heat dissipation system: Reduces the load on the overall structure.

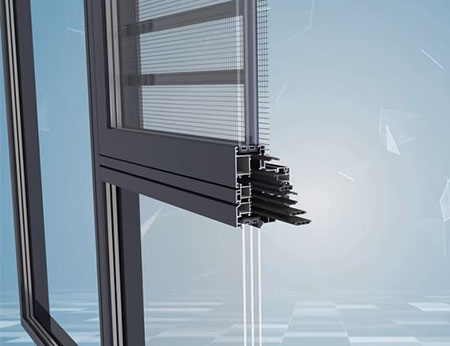

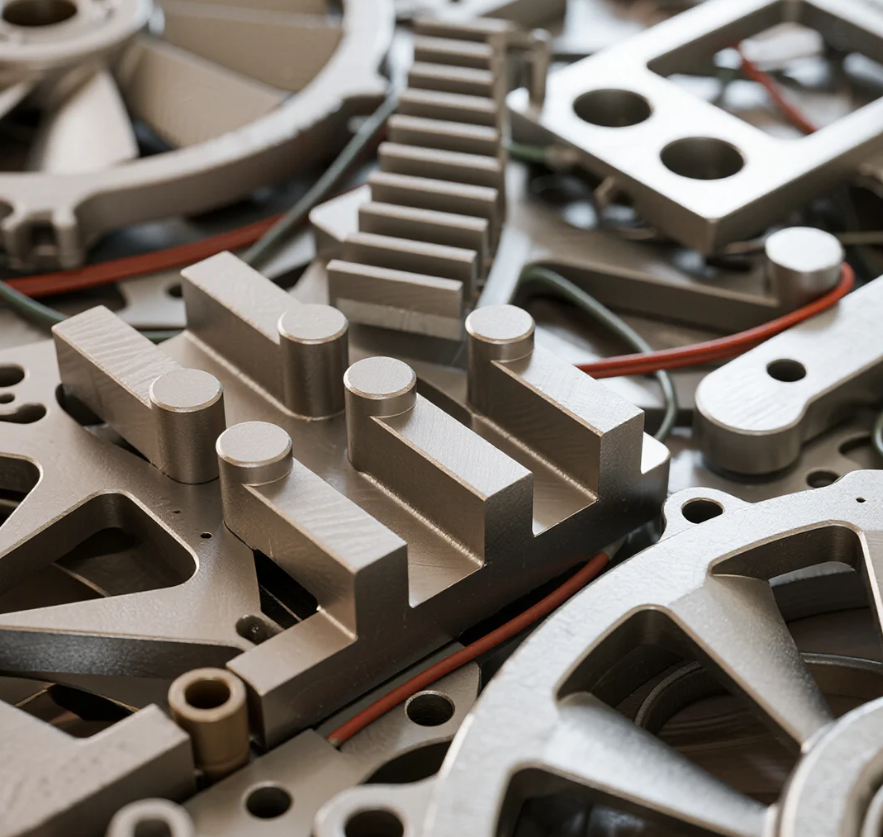

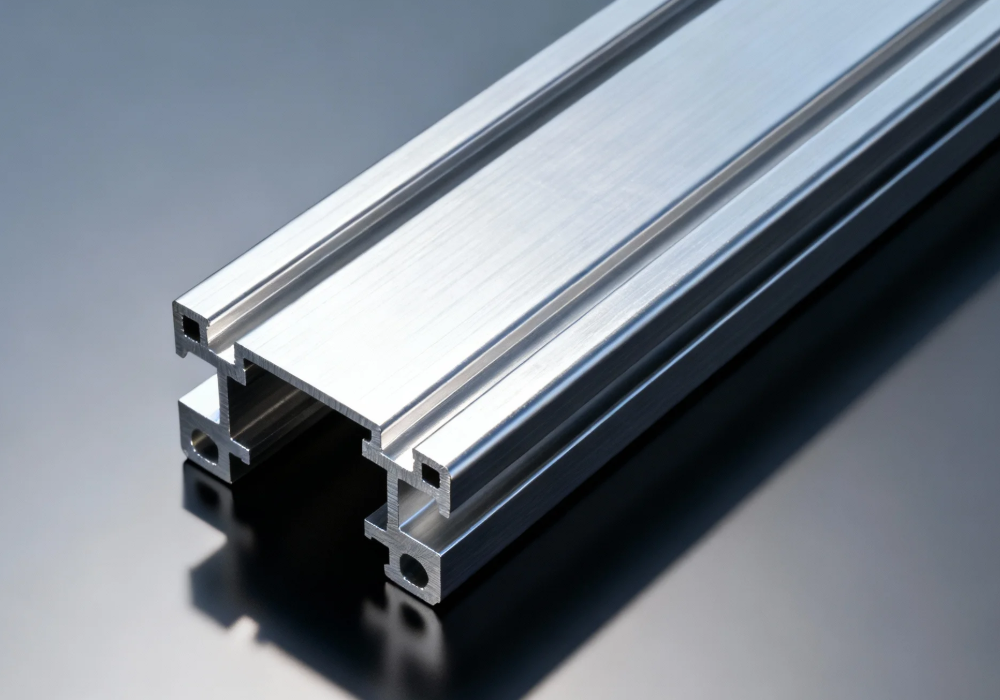

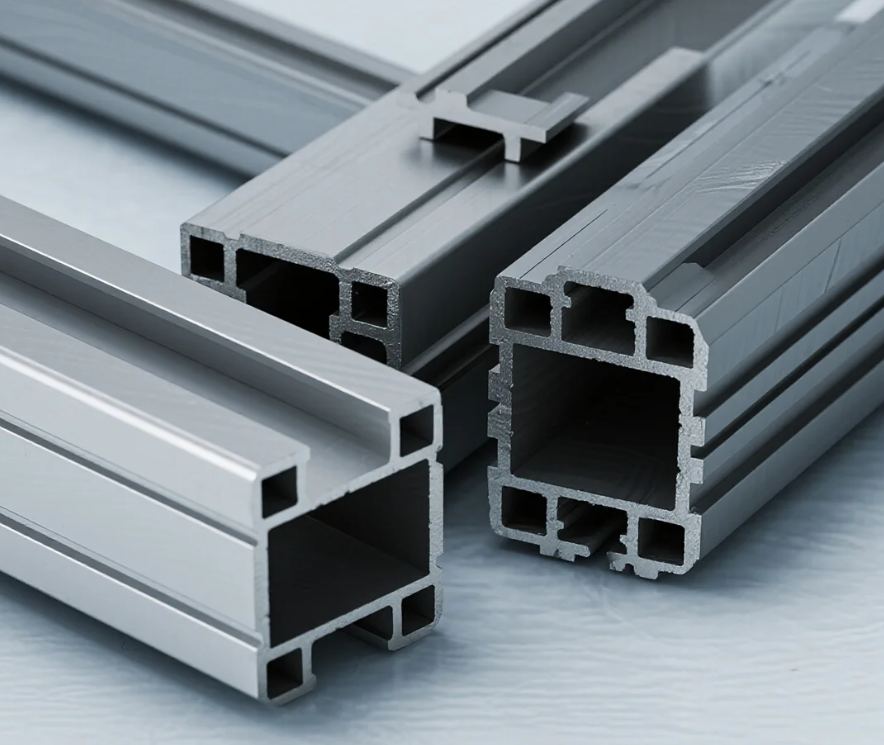

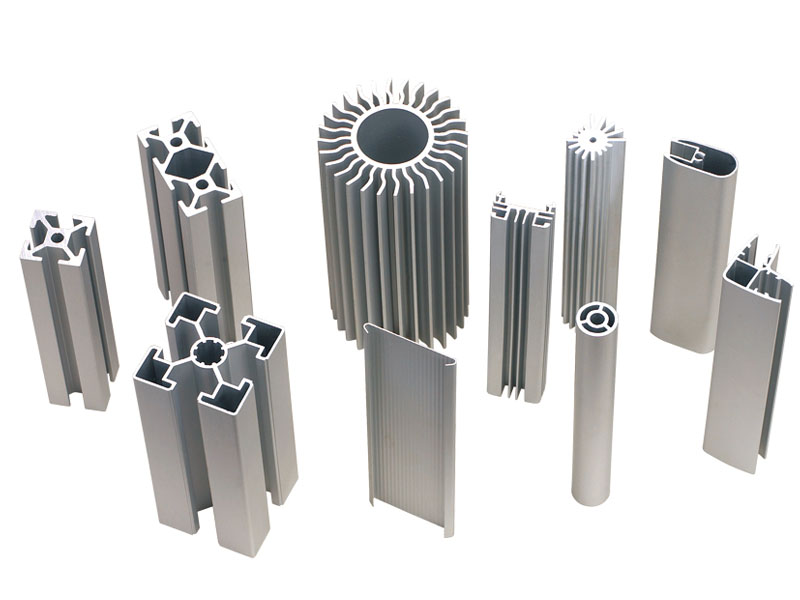

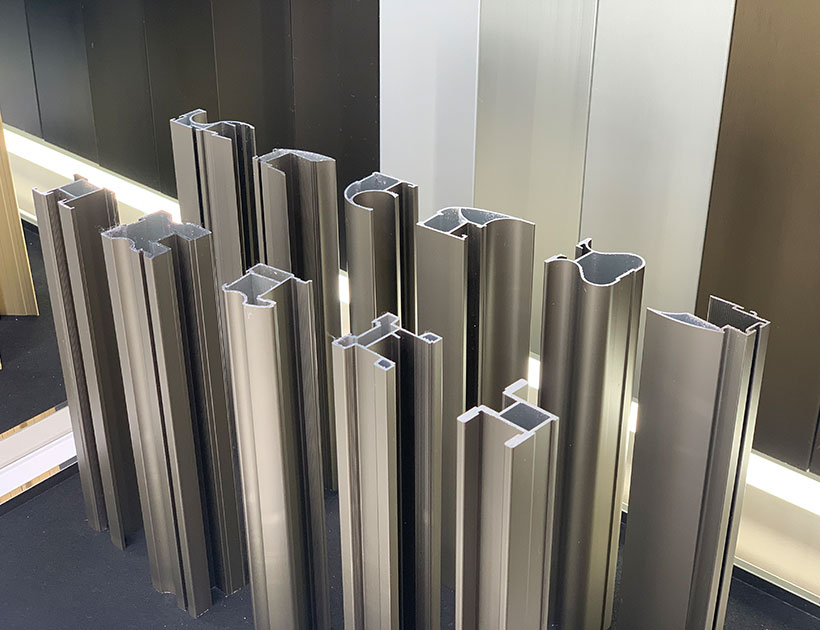

This is one of thr greatest advantages of aluminium profiles over other materials. The extrusion molding process is highly suitable for manufacturing heat sinks.

Complex shapes: Profiles with complex fin shapes can be extruded in one go through molds. The fins can be made very thin and very high to maximize the heat disspation area.

High production efficiency and low cost: Once the mold development is completed, the extrusion process can be carried out continuously and rapidly, and the cost of large-scale production is very low.

No secondary processing is required: Extruded profiles usually only need simple subsequent processing such as cutting and surface treatment to become finished profucts, reducing production steps and waste.

In contrast, although copper conducts heat better, it is softer and heavier, making it more difficult and costly to extrude complex shapes. Usually welding, milling or forging is adopted, which is also very costly.

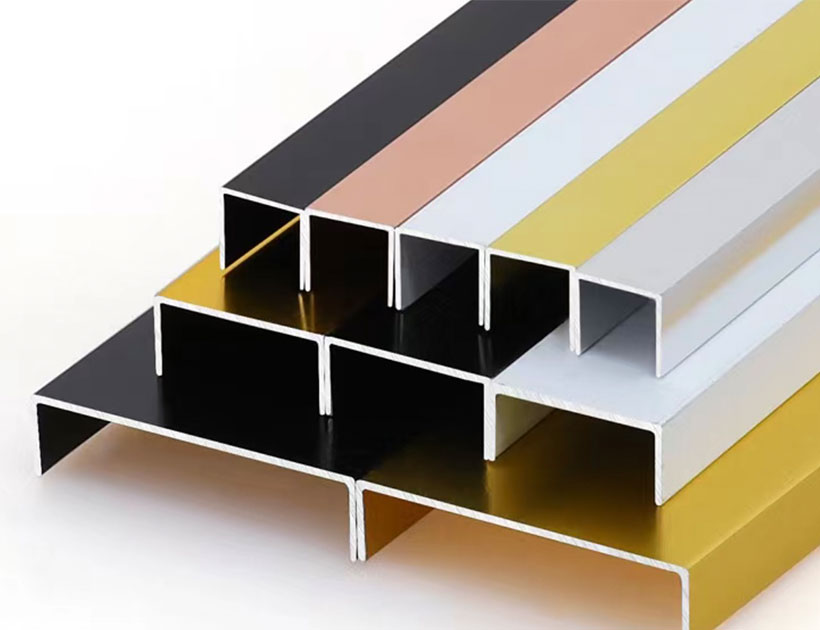

The surface of aluminium can be easily treated in various ways to enhance the performance of heat sinks-Anodizing: This is the most commonly used treatment method. By forming a hard oxide film on the surface of aluminium (such as black anodizing), the radiation rate can be increased, the insulation enhanced, and the corrosion resistance and wear resistance improved; Sandblasting and brushed: Mainly for aesthetic purposes.

Aluminium naturally forms a dense protective filem of aluminium oxide in the air. This film can prevent the internal metal from being further corroded and has good environmental adaptability. After anodic oxidation treatment, its corrosion resistance will be further enhanced.

Taking all the above advantages into account: The raw material cost is lower than that of copper, the processing technology (extrusion) is mature and efficient, and the yield rate is high, making the aluminium heat sink the choice with the highest cost performance ratio. For the vast majority of medium and low powder density scenarios, as well as some high powder density cooling scenarios, it can achieve the best balance between performance and cost.

Aluminium is a 100% recyclable and reusable metal, and the energy required for remelting and regeneration is only 5% of the initial production energy consumption, which is highly in line with the requirements of environmental protection and sustainale development.

| Characteristic | Al | Cu | Effect on heat sink |

| Thermal conductivity | Good (~200W/m`K) | Excellent (~400W/m`K) | Copper bases conduct heat faster |

| Density | Low (2.7g/㎤) | High (8.9g/㎤) | Aluminium heat sinks are lighter |

| Processability | Excellent (easy to extrude complex shapes) | Poor (Extrusion is difficult and costly) | Aluminium can be made into better fin shapes at a low cost |

| Cost | Low | High | Aluminium heat sinks offer an extremely high cost performance |

| Surface treatment | Easy | More difficult | Aluminium surface treatment can further enhance heat disspation |

Aluminium heat sink: It is widely applied in the vast majority of fields such as computer CPU/GPU, LED lighting, power adapters, consumer electronics, automotive electronics, frequency converters,etc.

Copper heat sinks: They are typically used in scenarious where the local heat flux density is extremely high (such as server CPU), or in a composite structure with copper bottom and aluminium fins (taking advantage of the rapid heat absorption of copper and the rapid heat dissipation of aluminium).

The use of aluminium profiles in heat sinks is a perfect balance achieved among multiple key factors such as thermal conductivity, quality, processing difficulty, and production cost. Although it is not the metal with the strongest heat conduction, its comprehensive advantages are unparalled, making it the most widely used and popular material in the field of heat dissipation.

Methods for distinguishing Indoor and Outdoor Aluminium Doors

Maintenance methods and tips for aluminium doors and windows

Characteristic of outward-opening and hung aluminium windows

Xinhe Aluminium Research: 7.14-7.18 Analysis of Aluminium Prices

Seven Benefits Of Using Aluminium Profiles In Curtain Wall Systems

The Application of Aluminium Profiles in New Energy Vehicles

The Composition and Application of Series 6 Aluminium Alloys

Top 5 Benefits of Using LED Aluminium Profiles in Modern Lighting

A Complete Guide to Aluminium Frame Profiles for Modern Structures

Exploring the Strength and Versatility of Aluminium Extrusion Profiles

How to Choose the Right Aluminium Profile Supplier for Your Project