The main benefits of using aluminium alloy wheels are as follows:

This is the foundation of all advantages of aluminium alloy wheels.

Reducing unsprung mass: Wheels, tires, brakes, suspension arms, etc. Fall under the category of “unsprung mass”, which refers to the weight not supported by the suspension system. Reducing unsprung mass has an immediate effect on performance improvement.

The benefits brought:

Enhance handling: The suspension system responds more quickly, the tires fit the road surface more closely, providing greater stability when cornering and passing over bumpy roads, and offering better grip. It is commonly know as “One pound lighter on your feet means ten pounds lighter on your vehicle.”

Improve acceleration and breaking performance: With a smaller moment of inertia, acceleration is smoother and breaking is less burdensome, which helps to shorten the braking distance.

Improving fuel economy: Reducing the overall vehicle weight, especially lightening the selected components that require repeated acceleration and deceleration, can directly lower fuel consumption (for fuel vehicles) or increase the driving range (for electric vehicles).

Good thermal conductivity: The thermal conducivity of aluminium alloy is much higher than that of steel, approximately three times that of steel.

The benefits brought:

Effective cooling for the braking system: During prolonged braking or intense driving, brake discs and calipers generate a significant amount of heat. Aluminium alloy wheels can quickly conduct this heat to the air, preventing the braking system from overheating and avoiding the “thermal attenuation” phenomen (i.e., the brakes fail due to overheating), which greatly enhances driving safety.

Protecting tires: Excessively high temperatures are the main cause o tire aging and blowouts. Better heat dissipation capacity helps to extend the lifespan of tires.

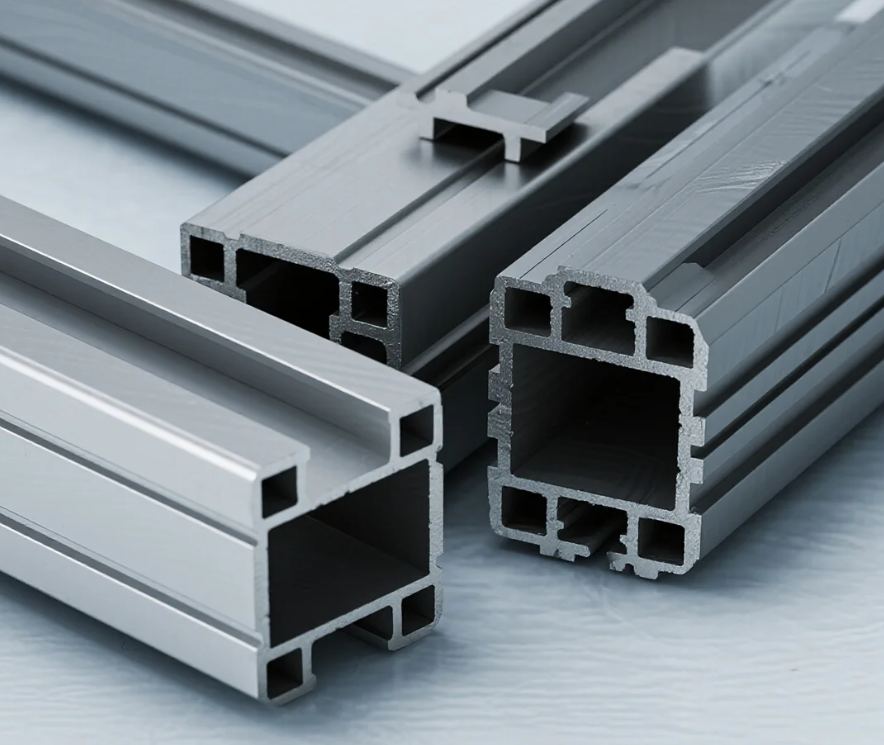

Advanced manufacturing process: Aluminium alloy wheels are usually manufactured by low-pressure casting, forging or spinning processes. Their dimensional accuracy and dynamic balance performance are inherently better than those of steel wheels made by stamping and welding.

Benefits brought:

Smoother ride: The high-precision wheels vibrate less when rotating at high speed, making the vehicle ride more smoothly and providing higher comfort.

Extending component lifespan: Less vibration means less impact on the suspension system, bearings and other components, which can extend the service life of these components.

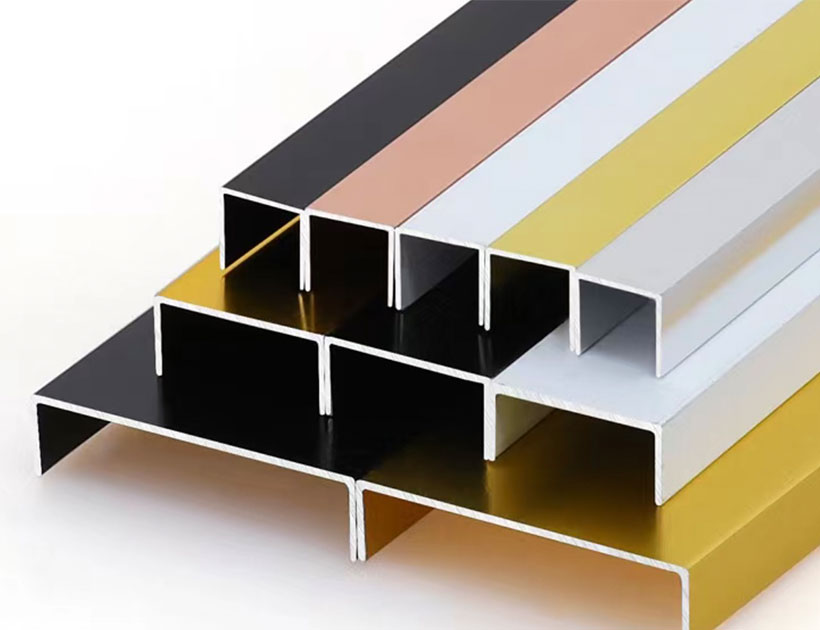

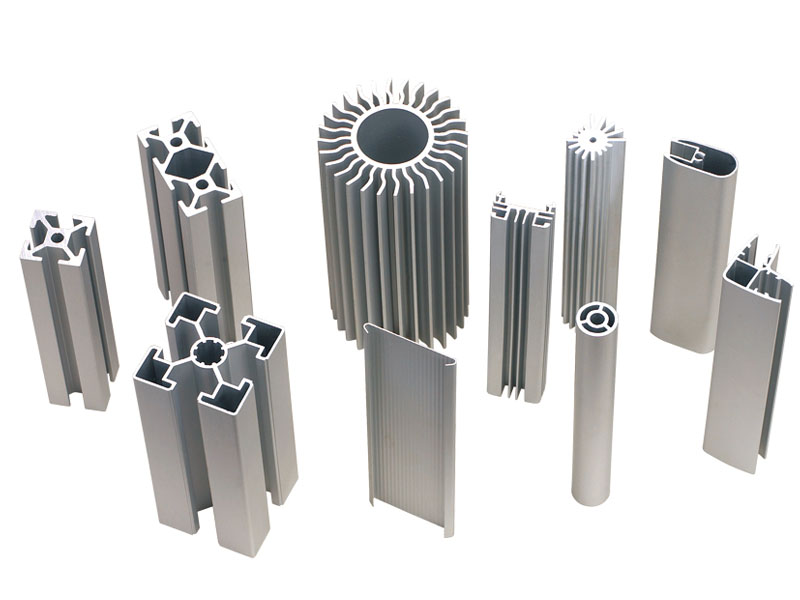

High degree of freedom in shaping: Aluminium alloy has excellent casting performance and can be used to create very complex and fashionable shapes, meeting the aesthetic demands of different consumers. From simple multi-spoke designs to complex two-tone and hollowed-out designs, the selection is extremely rich.

Diverse surface treatments: It can undergo various surface treatments such as polishing, electroplating, powder coating and brushing, presenting a bright color and being less prone to rust.

This is a comprehensive result, mainly due to the lightweighting mentioned in the first point. Although reducing the weight of a single wheel hub by a few kilograms may seem insignificant, when all four wheel hubs are combined and considering that it is a rotating part, its contribution to reducing fuel consumption is tangible.

| Characteristic | Aluminium wheel hub | Steel wheel hub |

| Weight | Light | Heavy |

| Heat dissipation property | Good | Poor |

| Precision and balance | High | Low |

| Aesthetic appeal | High and diverse in shape | Low and requires a decorative cover |

| Strength | Good, Excellent forging | Extremely high, with good toughness |

| Cost | Higher | Cheaper |

| Main advantages | Performance, handling, aesthetics, safety | Low cost, good toughness and easy to repair |

In summary, aluminium alloy wheels have brought about an all-round improvement in handling, safety, energy conservation and aesthetics for automobiles through their three core advantages: lightweight, good heat dissipation and high precision. Therefore, it has become the absolute mainstream configuration in today’s passenger car market.

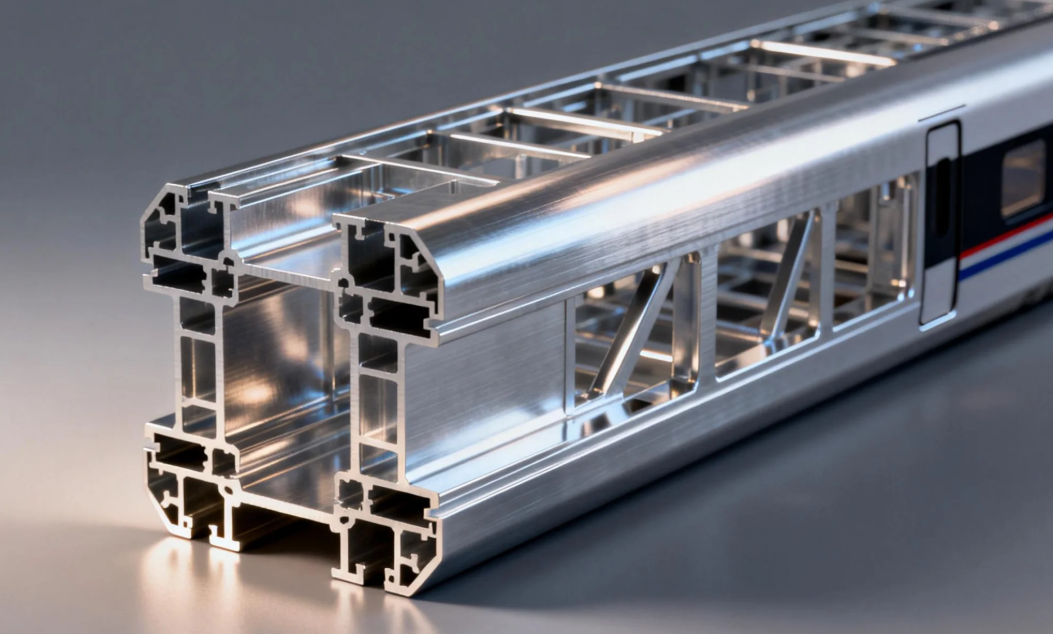

The advantages of using aluminium alloy for the main structure of high-speed train carriages

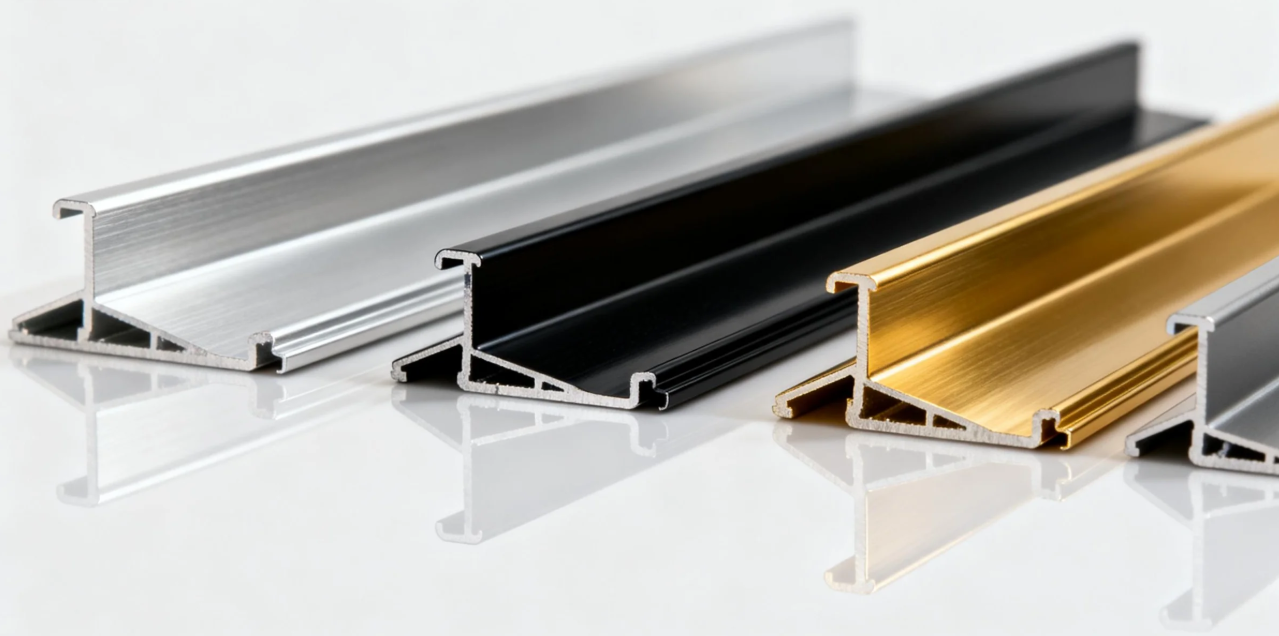

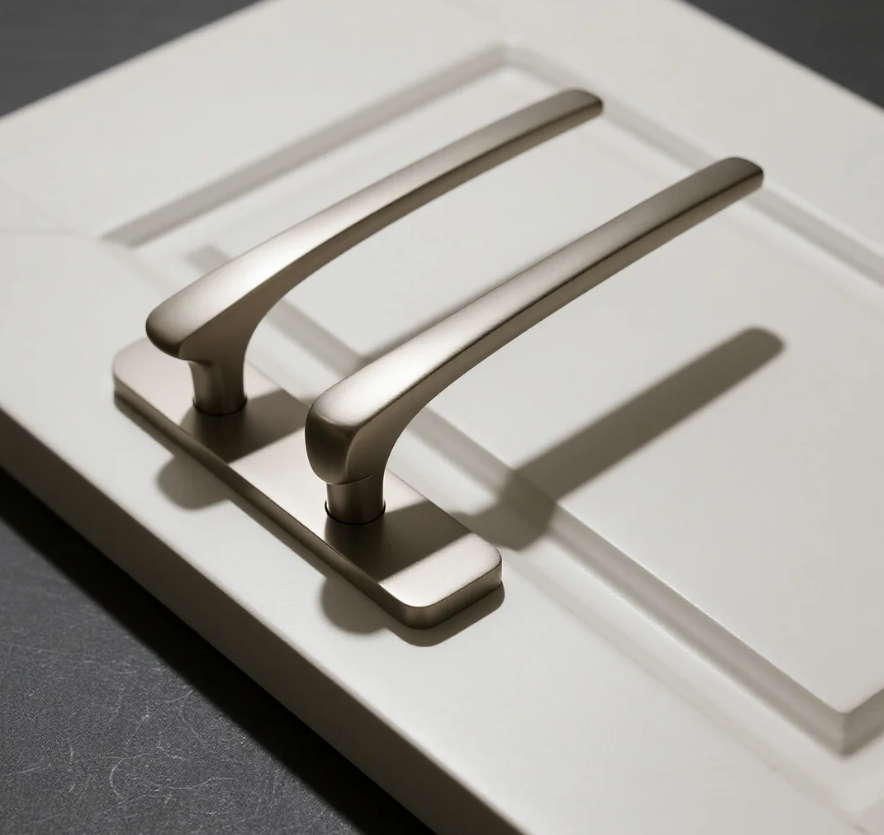

Methods for distinguishing Indoor and Outdoor Aluminium Doors

Maintenance methods and tips for aluminium doors and windows

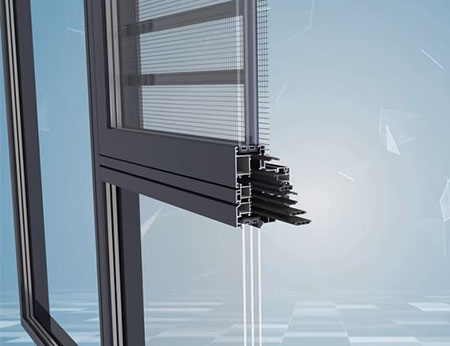

Characteristic of outward-opening and hung aluminium windows

Xinhe Aluminium Research: 7.14-7.18 Analysis of Aluminium Prices

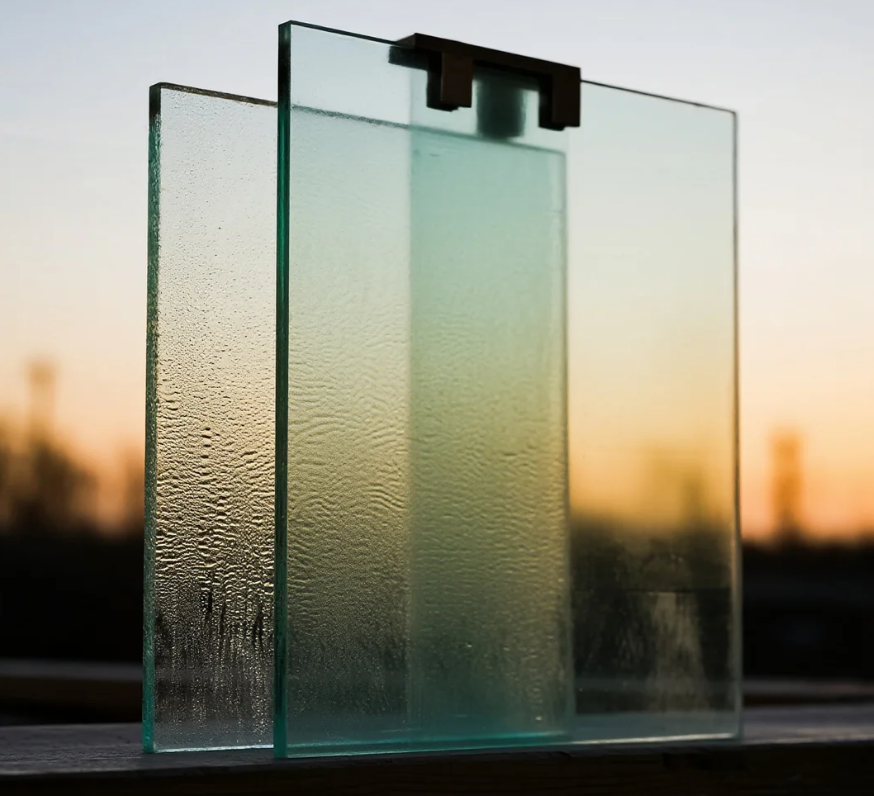

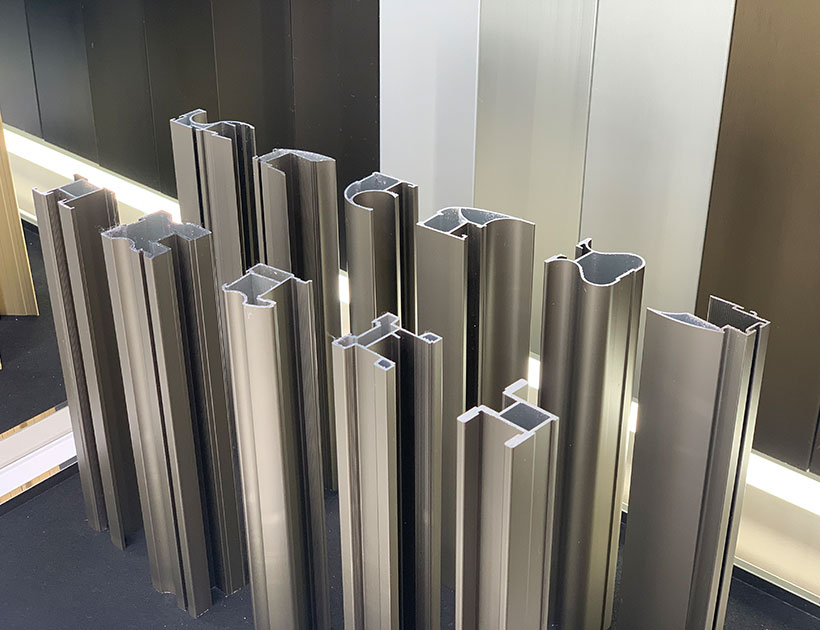

Seven Benefits Of Using Aluminium Profiles In Curtain Wall Systems

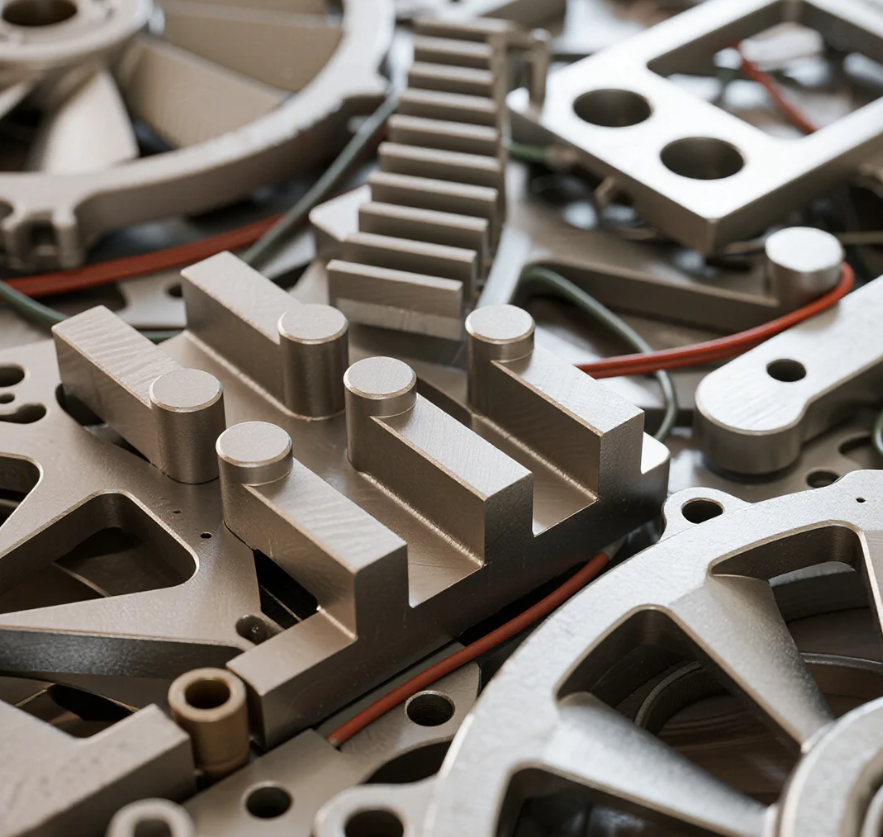

The Application of Aluminium Profiles in New Energy Vehicles

The Composition and Application of Series 6 Aluminium Alloys

Top 5 Benefits of Using LED Aluminium Profiles in Modern Lighting

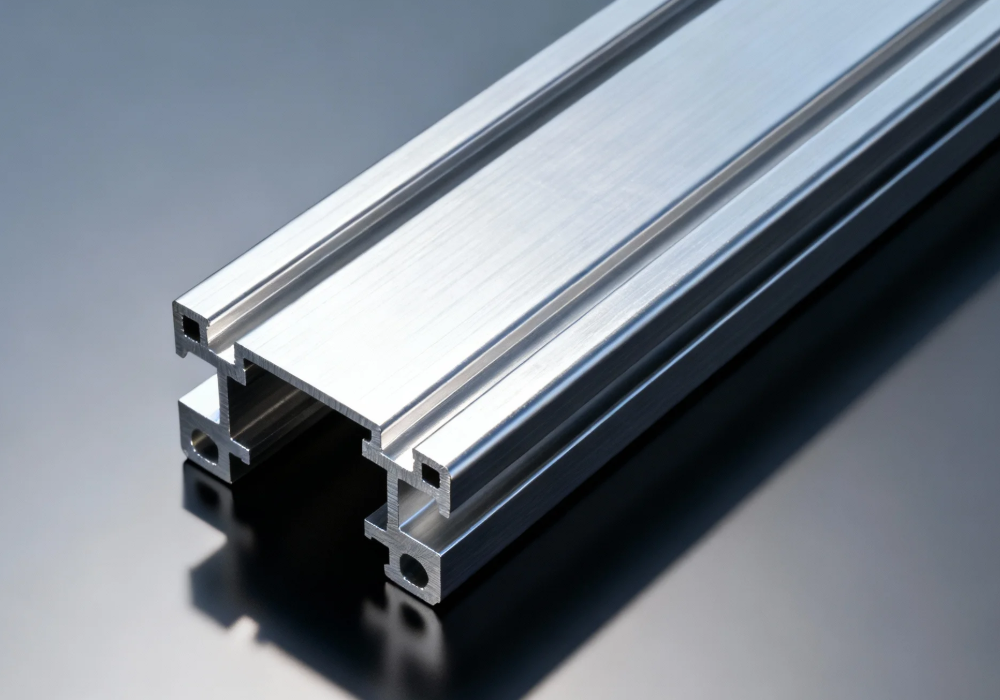

A Complete Guide to Aluminium Frame Profiles for Modern Structures

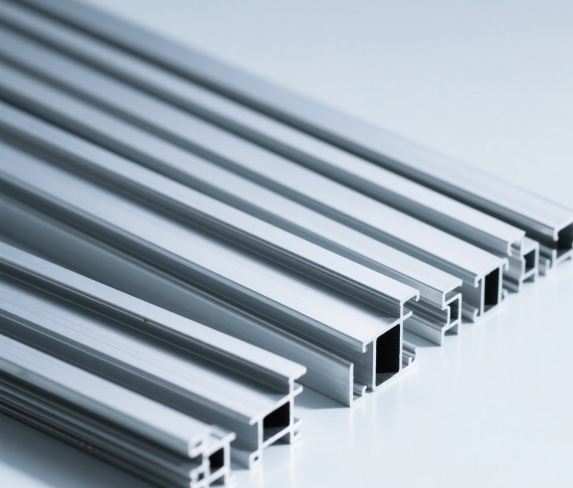

Exploring the Strength and Versatility of Aluminium Extrusion Profiles

How to Choose the Right Aluminium Profile Supplier for Your Project