Process principle–A dense layer of aluminium oxide (Al₂O₃) film is generated on the surface of aluminium through electrolysis, which enhances its corrosion resistance, hardness and decorative properties.

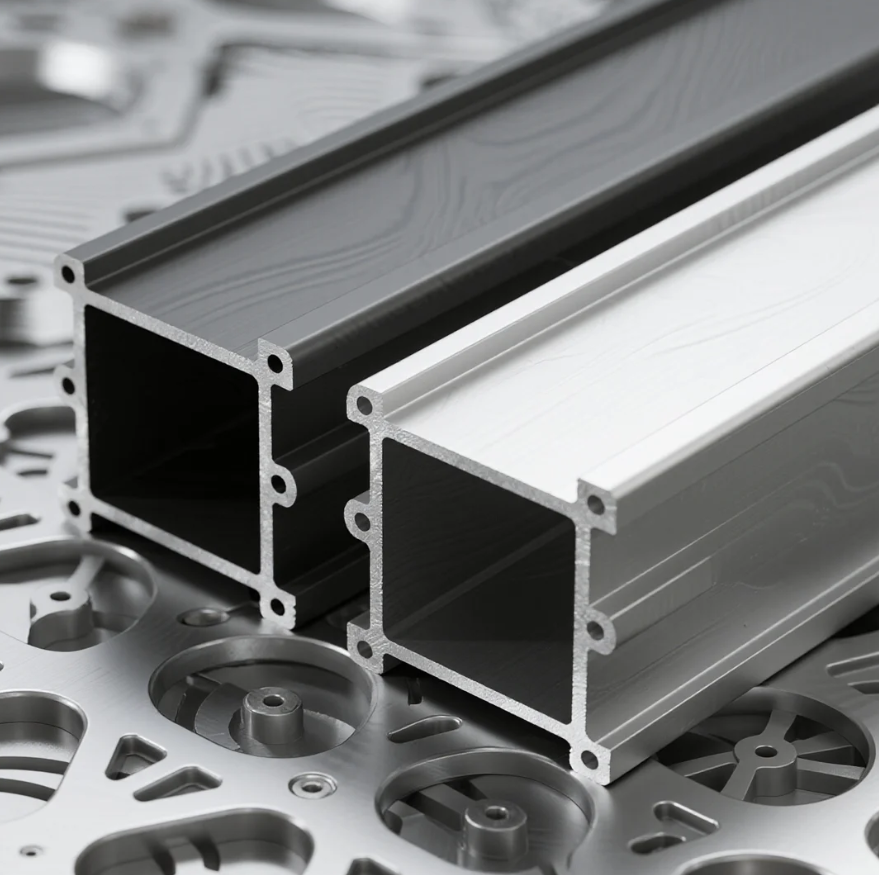

Characteristics–1.The hardness of the oxide film is high (HV 300-500) and it has good wear resistance.

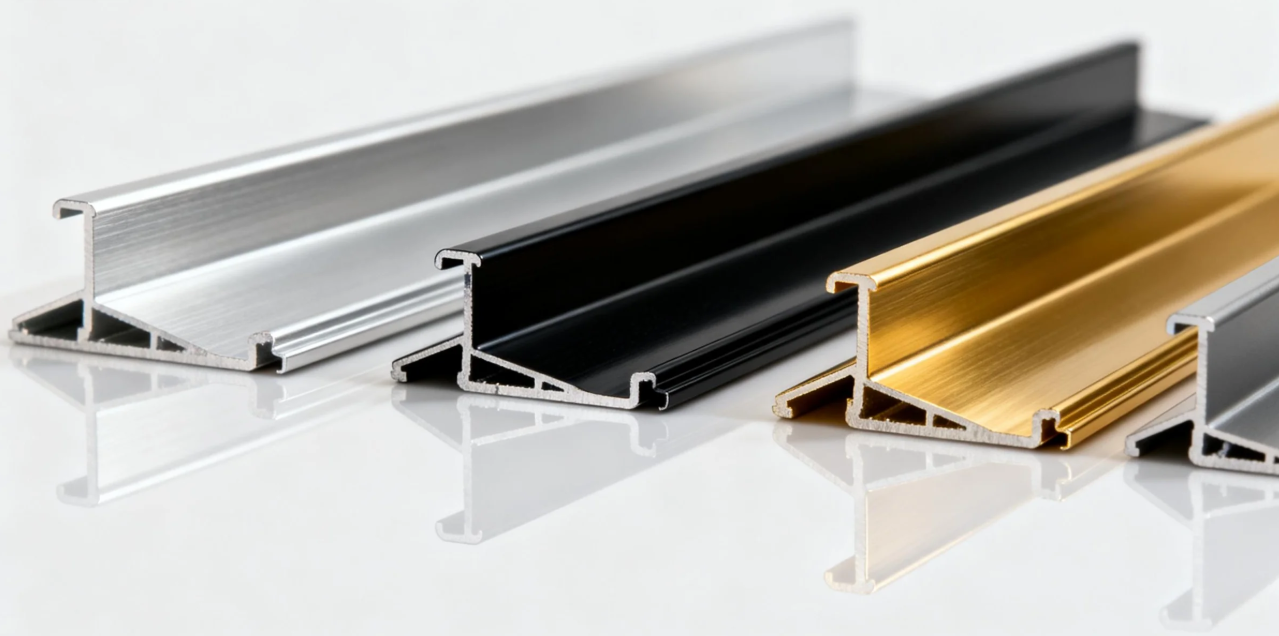

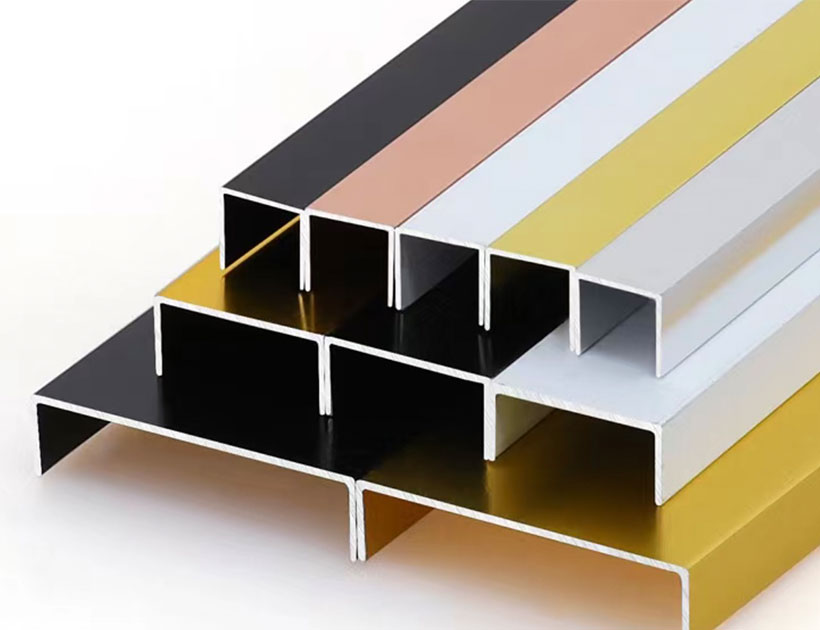

2.It can be made in various colors (silver white, black, gold, etc.)

3.It has strong weather resistance and is suitable for outdoor use.

4.The film thickness is limited and it is not suitable for strong acid/ strong alkali environments.

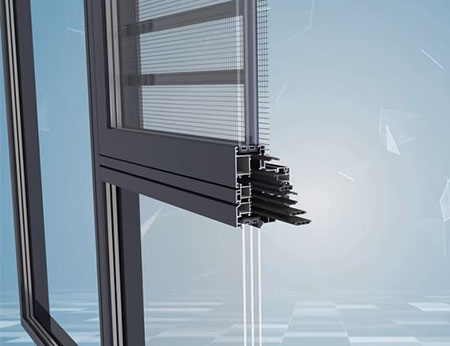

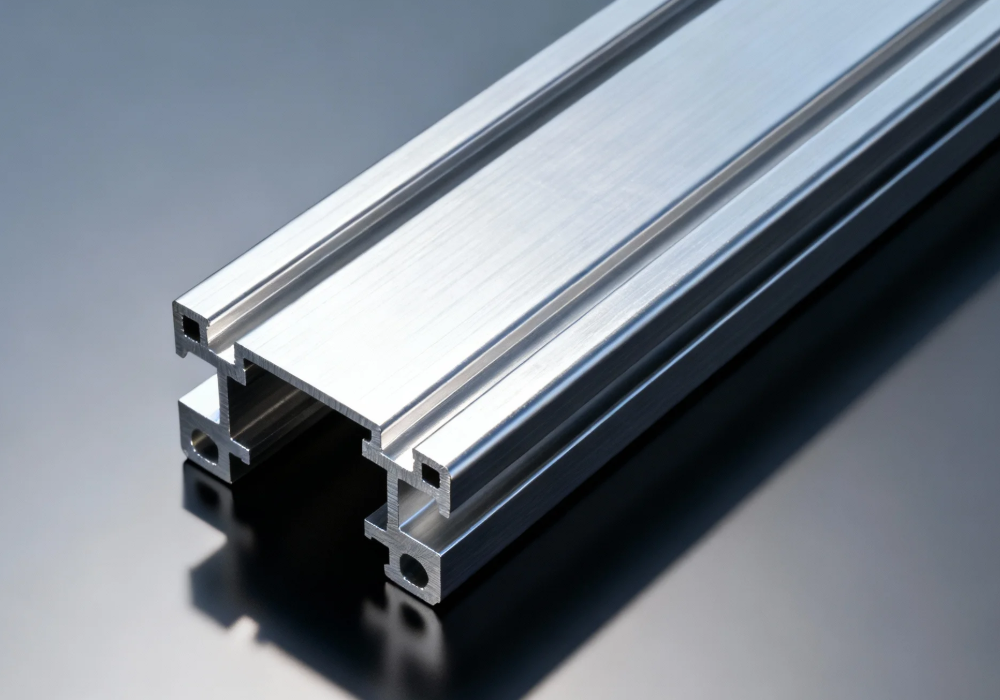

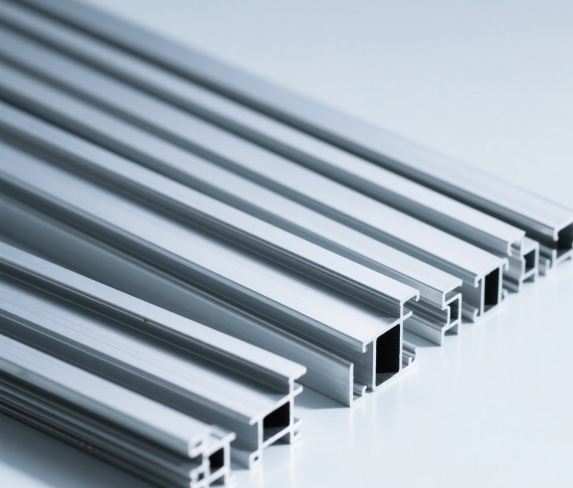

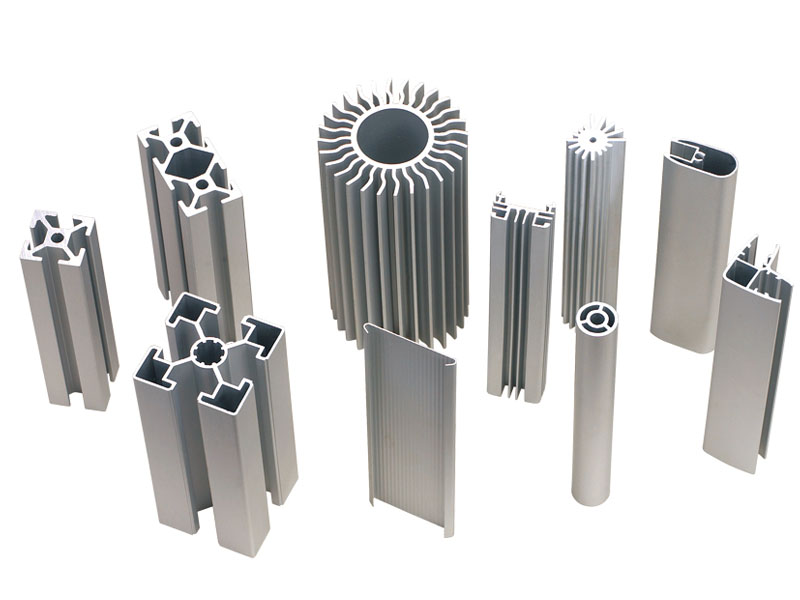

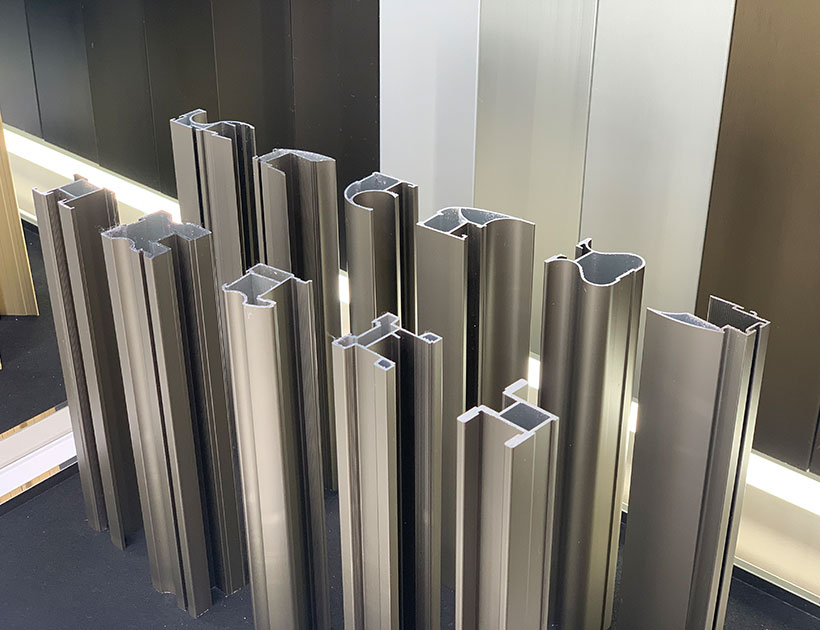

Application scenarios–Architectural aluminium profiles (doors and windows, curtain walls), electronic products (mobile phone frames), industrial accessories.

Process principle— Aluminium profiles are immersed in the electrophoretic paint tank as electrodes. After being electrified, charged resin particles deposit to form a uniform coating.

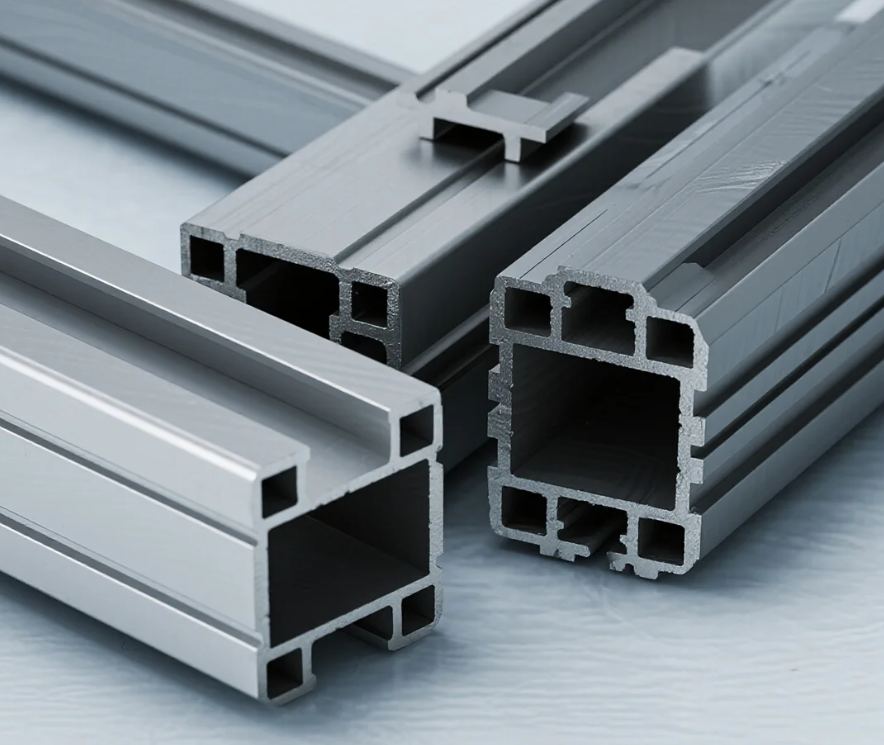

Characteristics–1.The coating is uniform and has a strong ability to cover dead corners, making it suitable for profiles with complex cross-sections.

2.It has good corrosion resistance

3.The color is relatively simple, mostly light, and the hardness is lower than powder coating.

Application scenarios–Automotive aluminium parts, electronic enclosures, high-end building materials.

Process principle–Electrostatic adsorption powder coating is formed by high-temperature curing to create a coating.

Characteristics–1.Environmentally friendly with no VOC, thick coating and diverse colors.

2.The corner coverage is slightly poor and may discolor in high-temperature environments.

Application scenarios–Architectural aluminium profiles, household appliances, outdoor facilities.

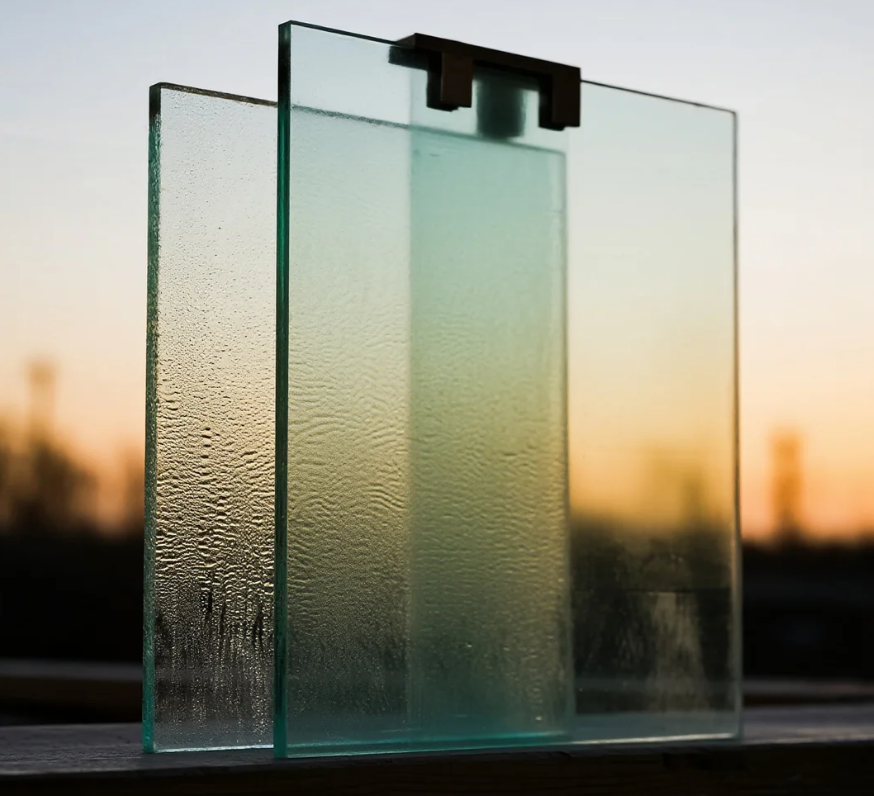

Process principle–PVDF coating is adopted, with multi-layer spraying and high-temperature curing.

Characteristics— 1.Super weather resistance, can be up to 20 years without powder.

2.UV-resistant, acid and alkali resistant, and has good self-cleaning properties.

Application scenarios–High-end buildings (airports, landmark curtain walls), coastal areas or regions with severe industrial pollution.

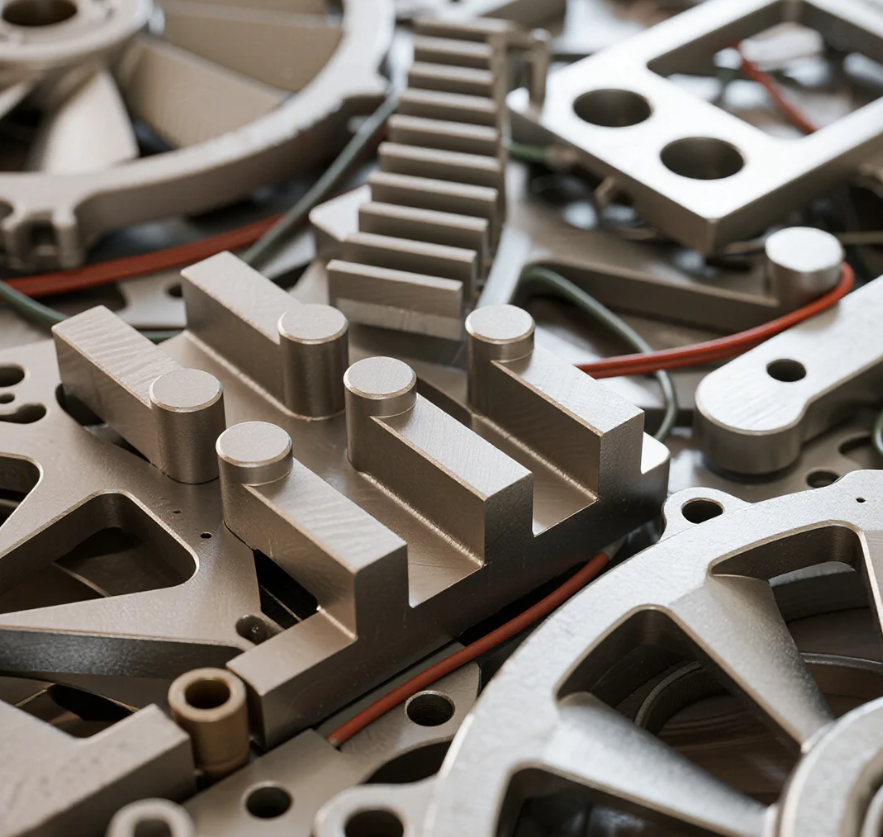

Process principle–Mechanical processing creates a uniform texture or mirror-like effect on the surface.

Characteristics–1.Aesthetically pleasing and enhances texture.

2.It has no anti-corrosion function and needs to be used in combination with anodizing or powder coating.

Application scenarios–Electronic products (mobile phones, laptops), decorative building materials.

Process principle–High-speed spraying of sand particles creates a matte and rough texture on the surface.

Characteristics–1.Enhance the adhesion of the coating and hide surface defects.

2.It can be combined with anodizing or powder coating to enhance the texture.

Application scenarios–Industrial equipment, high-end furniture

Outdoor architecture: PVDF>Powder coating>Anodized

Interior decoration: Anodized (aesthetics)

Industrial anti-corrosion: Double-layer protection by electrophoresis and powder coating

The selection of surface treatment for aluminium profiles needs to comprehensively consider factors such as weather resistance, cost, aesthetics, and environmental protection. Different process can be used separately or in combination to meet the requirements.

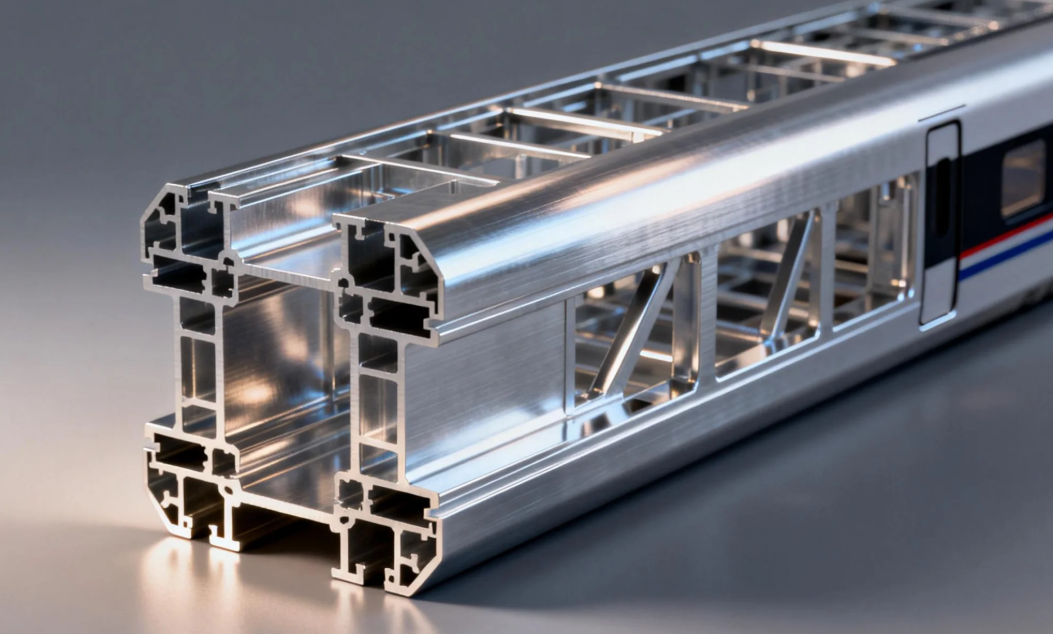

The advantages of using aluminium alloy for the main structure of high-speed train carriages

Methods for distinguishing Indoor and Outdoor Aluminium Doors

Maintenance methods and tips for aluminium doors and windows

Characteristic of outward-opening and hung aluminium windows

Xinhe Aluminium Research: 7.14-7.18 Analysis of Aluminium Prices

Seven Benefits Of Using Aluminium Profiles In Curtain Wall Systems

The Application of Aluminium Profiles in New Energy Vehicles

The Composition and Application of Series 6 Aluminium Alloys

Top 5 Benefits of Using LED Aluminium Profiles in Modern Lighting

A Complete Guide to Aluminium Frame Profiles for Modern Structures

Exploring the Strength and Versatility of Aluminium Extrusion Profiles

How to Choose the Right Aluminium Profile Supplier for Your Project