The use of aluminium profiles in curtain wall systems has significant advantages, making it the preferred material for modern buildings, especially high-rise and landmark buildings. The following are the core benefits of aluminium profiles in curtain wall applications.

Light in weight:The density of aluminium is only 2.7g/cm ³ (approximately one-third that of steel), significantly reducing the load on the building structure by curtain walls, making it particularly suitable for super high-rise buildings.

High strength: Through alloying (such as 6061,6063) and heat treatment. The tensile strength can reach 200-300 Mpa, meeting the requirements of wind pressure resistance and earthquake resistance.

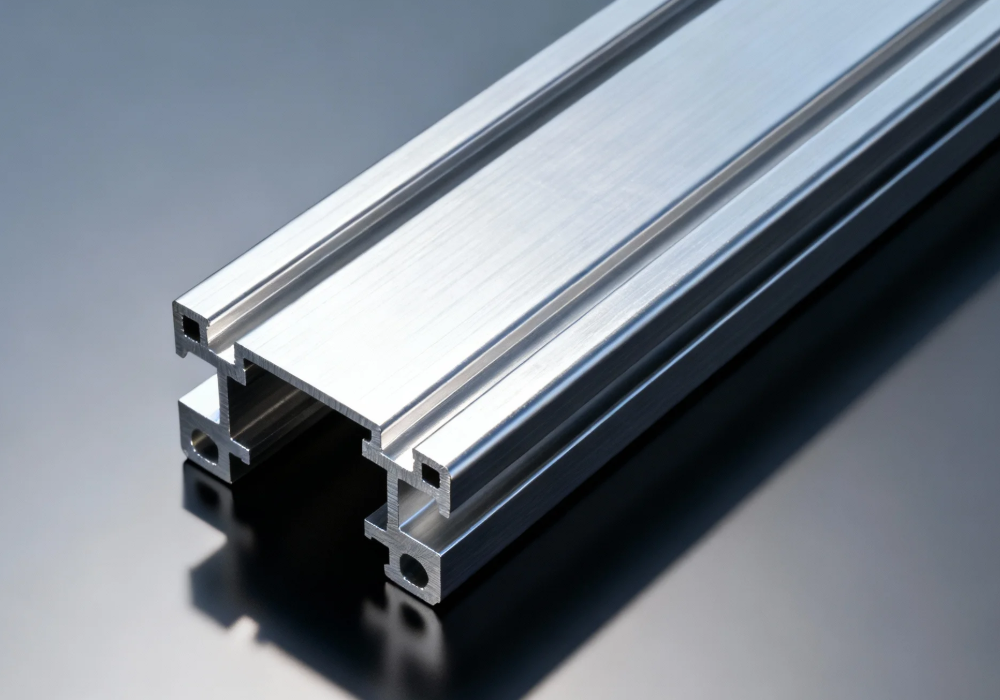

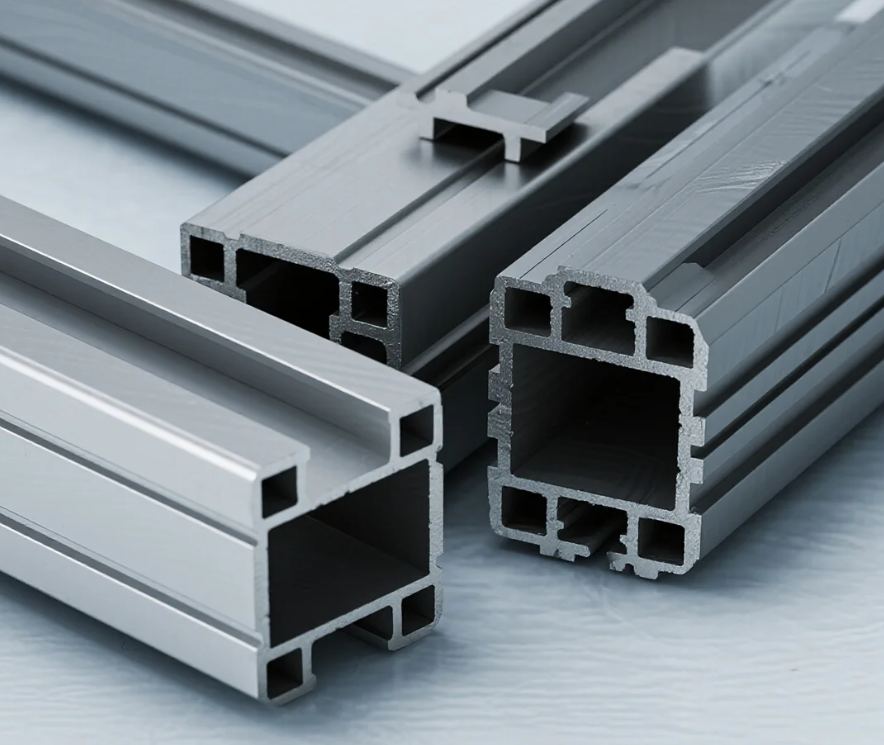

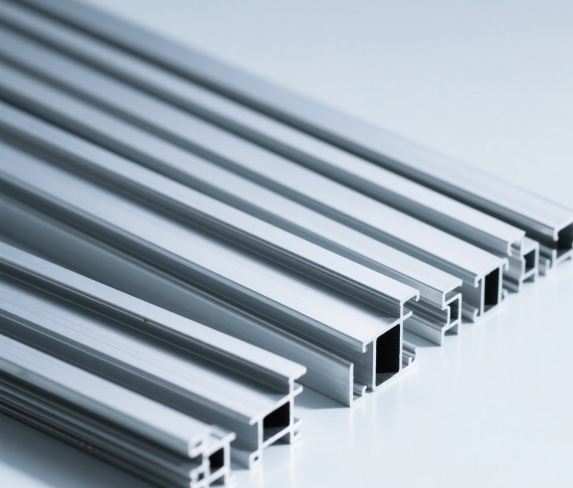

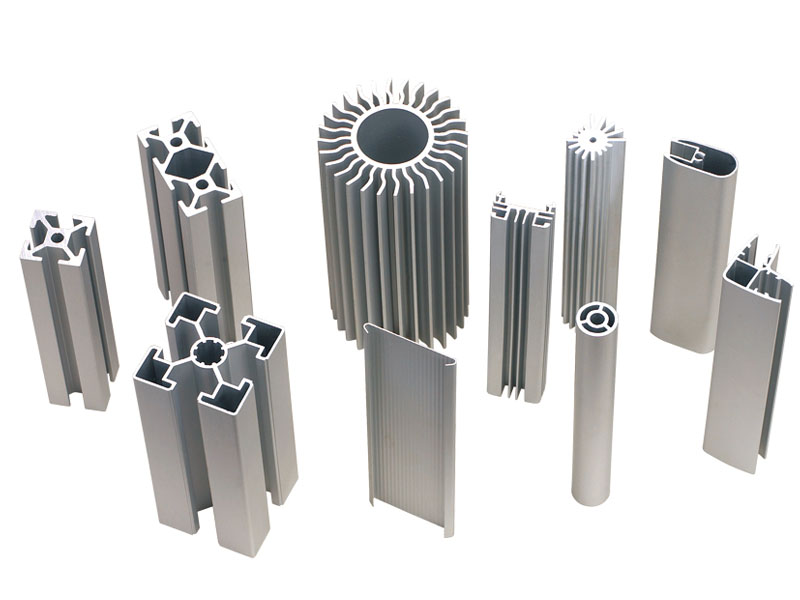

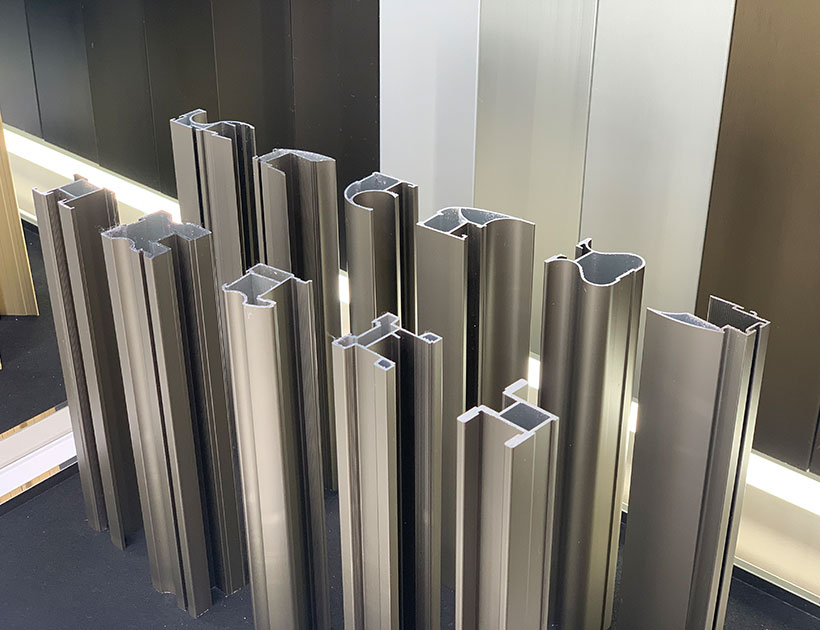

Flexible structural design: It can be extruded into complex cross-sections (such as multi-chamber structures),achieving a balance between high strength and lightweight.

Natural anti-corrosion: The surface of aluminium is prone to form a dense oxide film (Al₂O₃) which is resistant to atmospheric corrosion and suitable for coastal and high-humidity areas.

Surface treatment enhanced: Anodized–The film thickness is 10-25μm, which extends the service life;

PVDF–Resistant to ultraviolet rays and acid rain, with long-lasting color retention.

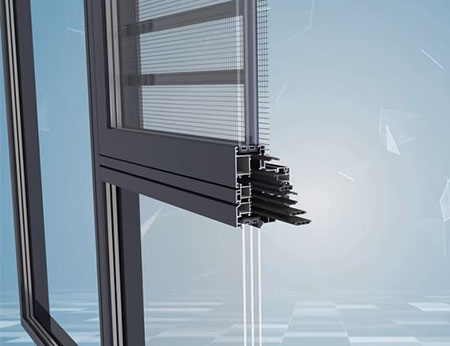

High degree of freedom in extrusion molding: Any cross-sectional shape can be customized (such as invisible drainage channels, thermal break structures).

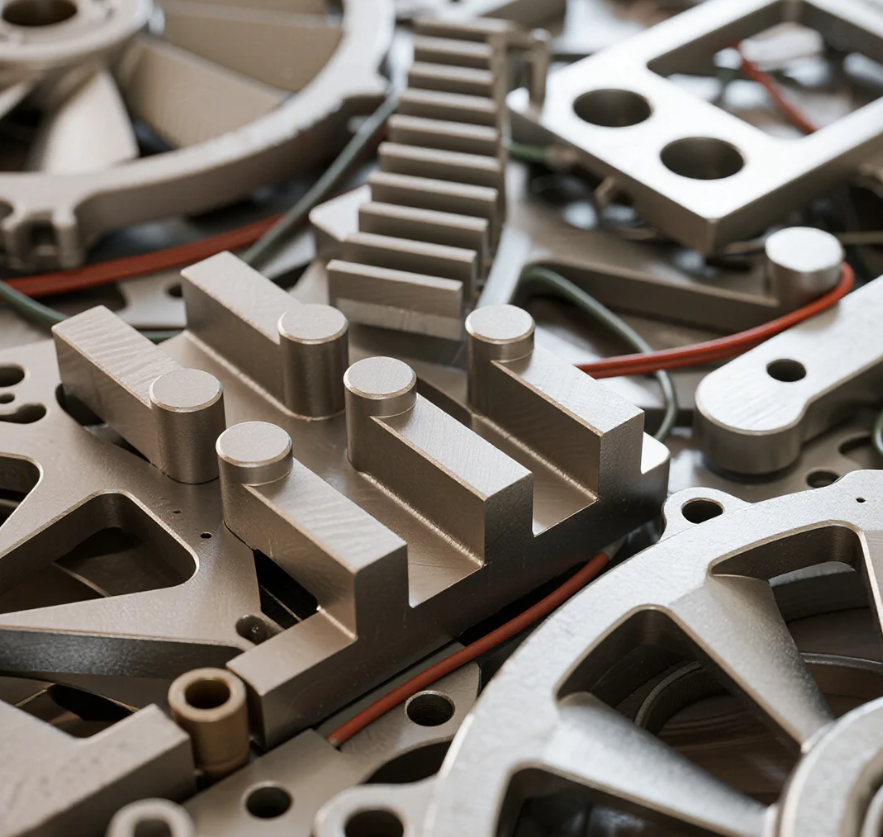

Easy to installation: Aluminium profiles can be quickly assembled through bolts and corner codes, reducing on-site welding and shortening the construction period by 30% to 50%.

High dimensional accuracy:The tolerance can be controlled±0.1 mm to ensure the sealing and flatness of the curtain wall.

Thermal insulation performance: Utilizing thermal break aluminium profiles(PA66 nylon thermal insulation strips), the thermal conductivity is as 1.8 to 3.5W/(m·K), reducing building energy consumption by over 40%.

Recyclability: The aluminium recovery rate exceeds 95%, and the energy consumption for recycled aluminium is only 5% of that for primary aluminium (meting LEED certification requirements).

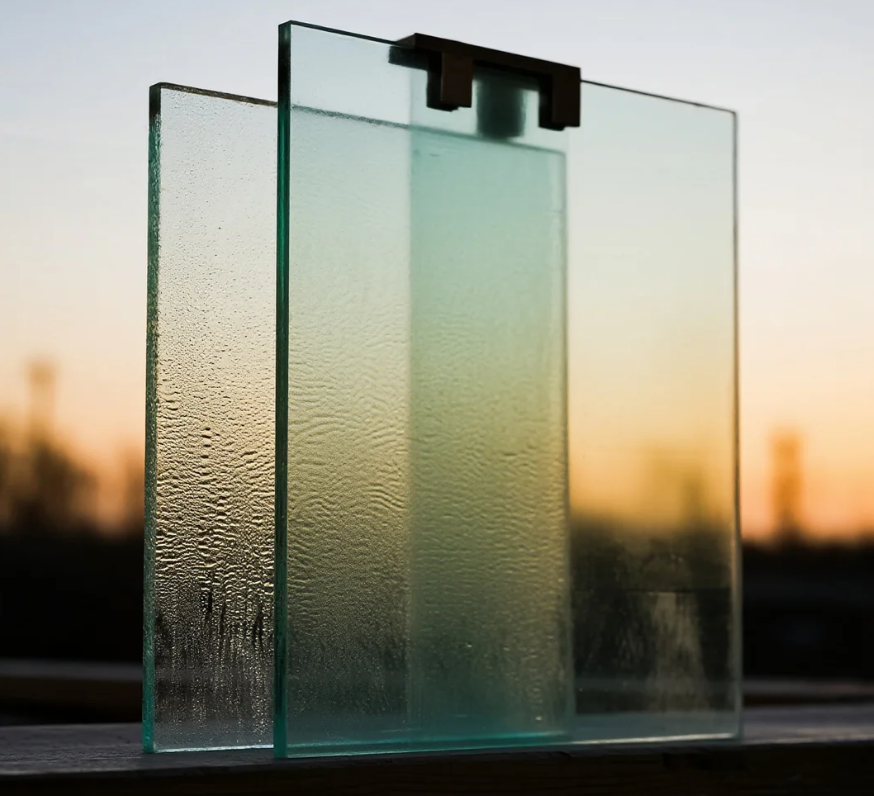

Green building adaptation: In combination with Low-E glass, the overall energy conservation of the curtain wall system is achieved.

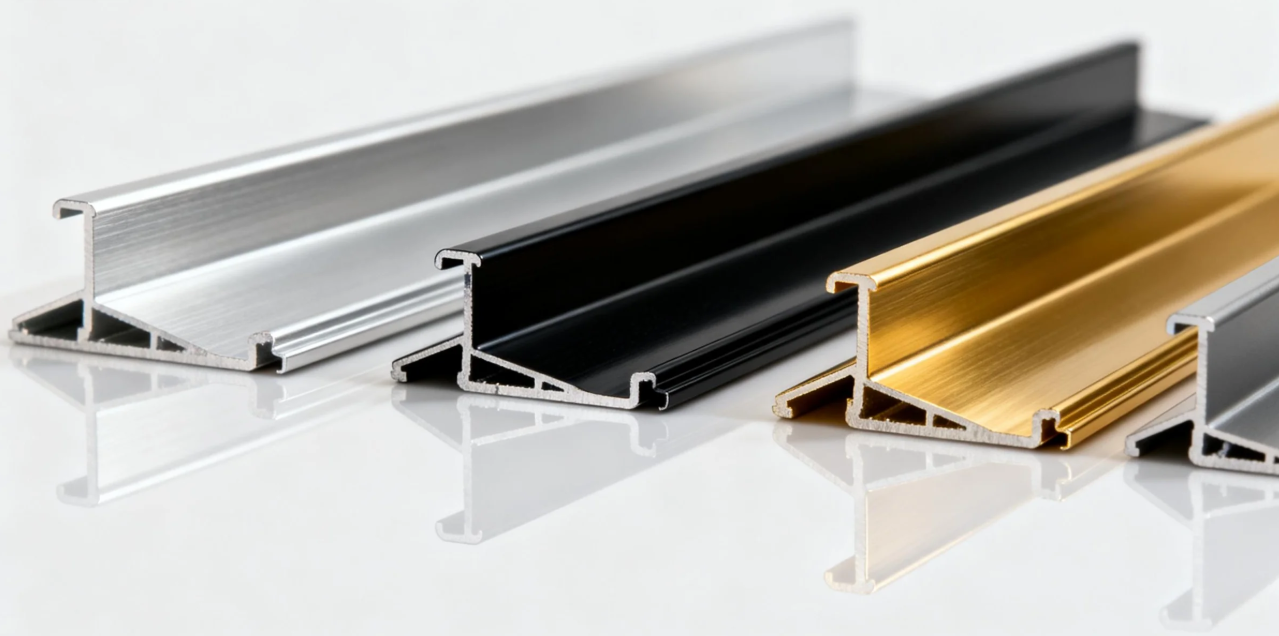

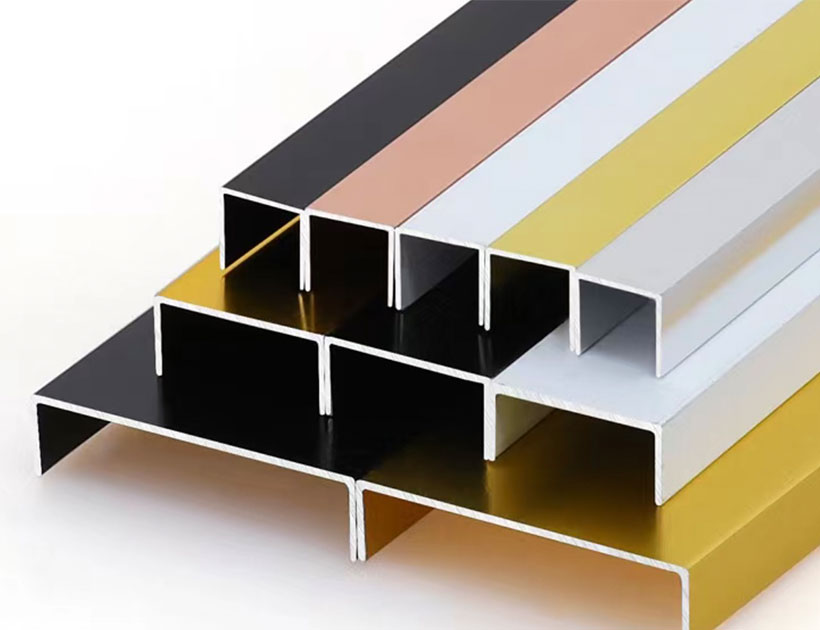

Colorful: Through processes such as powder coating and wood grain transfer printing, over 2000 colors and textures (such as stone imitation and metal brushing) can be achieved.

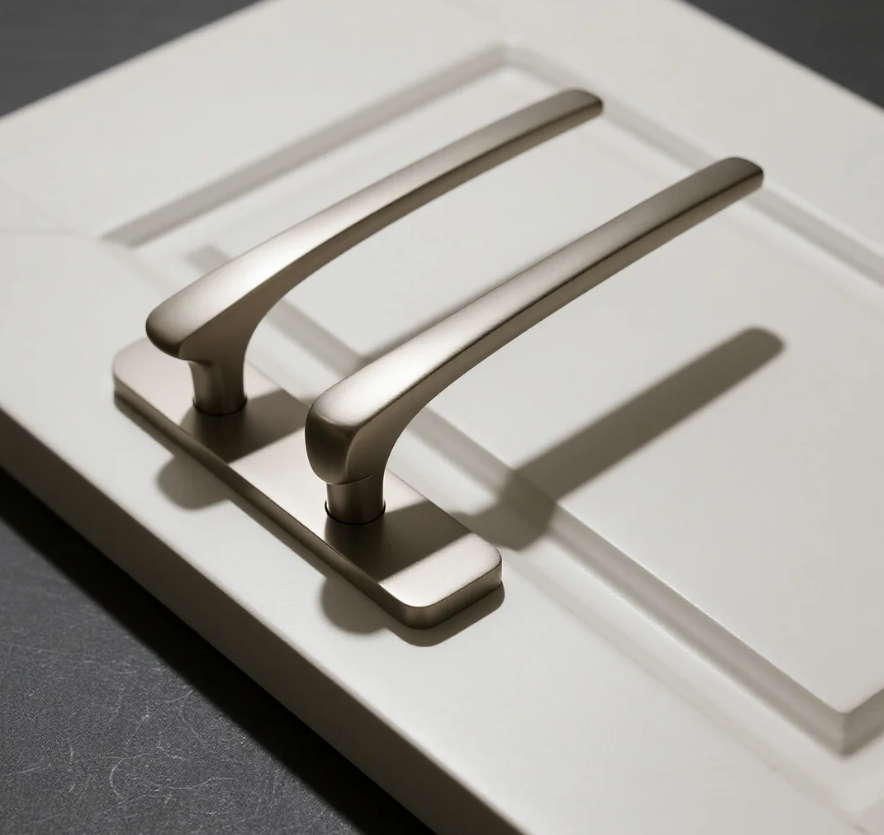

Strong sense of modernity: The lines are simple and smooth, suitable for modern architectural styles such as glass curtain walls and unitized curtain walls (such as Beijing Daxing Airport).

Hidden structure design: Aluminium profiles can integrate drainage and ventilation functions to keep the appearance clean.

Low life cycle cost: Although the initial cost is higher than that of steel, it is maintenance-free, has a long service life, and reduces the total cost.

Easy to maintenance: The surface treatment process has strong anti-fouling ability and only requires regular clean water rinsing.

Fire resistance: The melting point is approximately 660℃, but it can meet the A2-level non-combustible material standard through alloying and fireproof coating.

Impact resistance: When combined with steel cores or reinforcing ribs, it can pass extreme weather tests such as typhoons and hail.

Super high-rise building: Burj Khalifa in Dubai (unitized aluminium profile curtain wall)

Irregular structure: Guangzhou Opera House (curved aluminium profiles+glass combination)

Energy-saving Benchmark: Xiongan New Area Citizen Service Center (integrated of thermal break aluminium profiles and photovoltaic curtain wall)

In coastal and highly polluted areas: PVDF aluminium profiles should be given priority.

In high-cold regions: select multi-chamber thermal break aluminium profiles to enhance thermal insulation.

Irregular-shaped curtain wall: It adopts 3D curved aluminium profiles or segmented splicing technology.

The application of aluminium profiles in curtain walls continues to innovate, such as photovoltaic integrated aluminium profiles curtain walls and intelligent ventilation aluminium profiles systems.

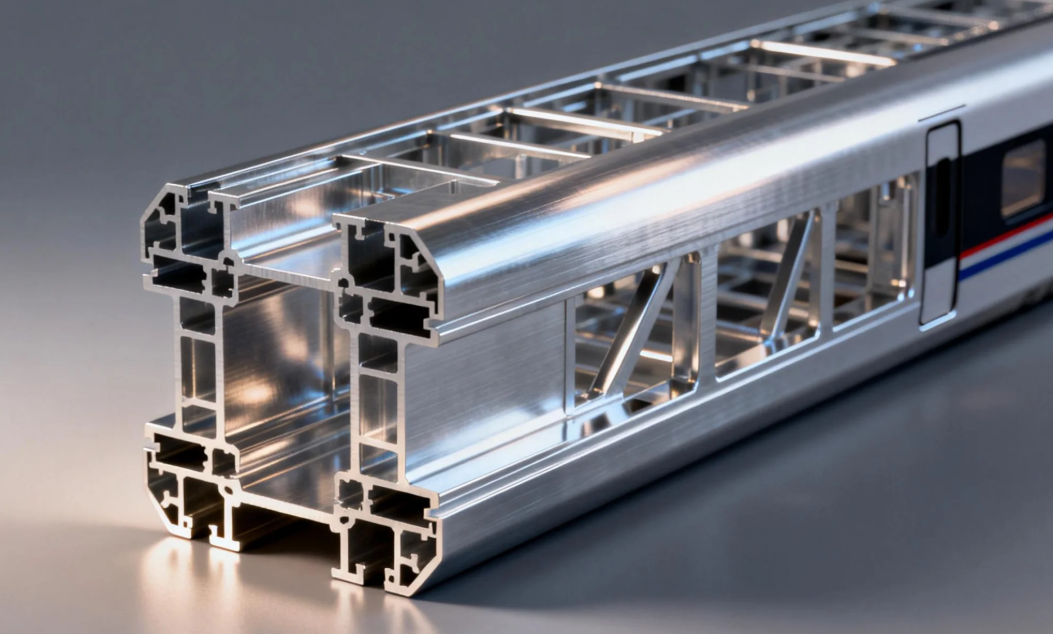

The advantages of using aluminium alloy for the main structure of high-speed train carriages

Methods for distinguishing Indoor and Outdoor Aluminium Doors

Maintenance methods and tips for aluminium doors and windows

Characteristic of outward-opening and hung aluminium windows

Xinhe Aluminium Research: 7.14-7.18 Analysis of Aluminium Prices

The Application of Aluminium Profiles in New Energy Vehicles

The Composition and Application of Series 6 Aluminium Alloys

Top 5 Benefits of Using LED Aluminium Profiles in Modern Lighting

A Complete Guide to Aluminium Frame Profiles for Modern Structures

Exploring the Strength and Versatility of Aluminium Extrusion Profiles

How to Choose the Right Aluminium Profile Supplier for Your Project