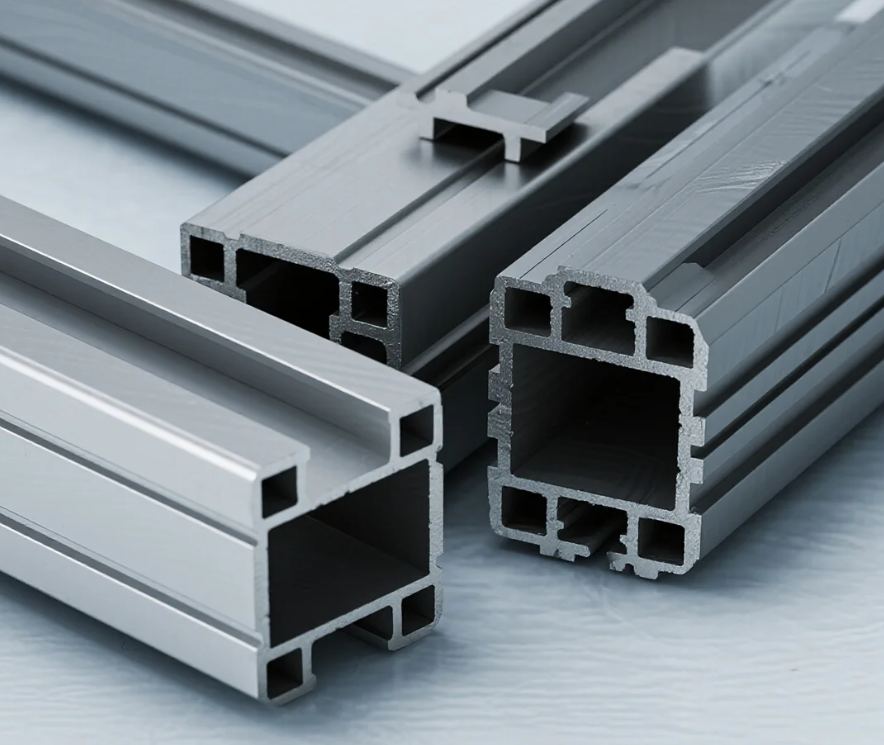

The use of aluminium profiles in cabinets can significantly enhance functionality, durability and aesthetics, and is particularly suitable for modern kitchens and custom home needs. The following is an analysis of the specific advantages and applicable scenarios.

In the high-humidity kitchen environment: Aluminium profiles are completely resistant to water vapor erosion, avoiding the common problems of expansion and mold that wooden cabinets encounter.

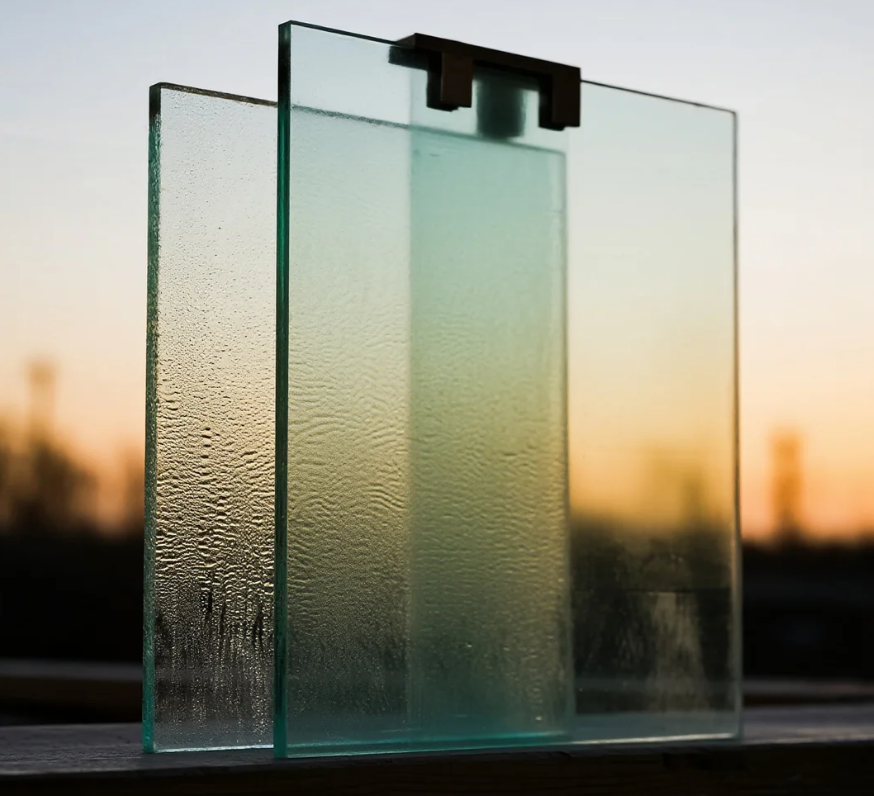

Direct contact sink area: Aluminium frame combined with stone/glass panels, suitable for damp areas.

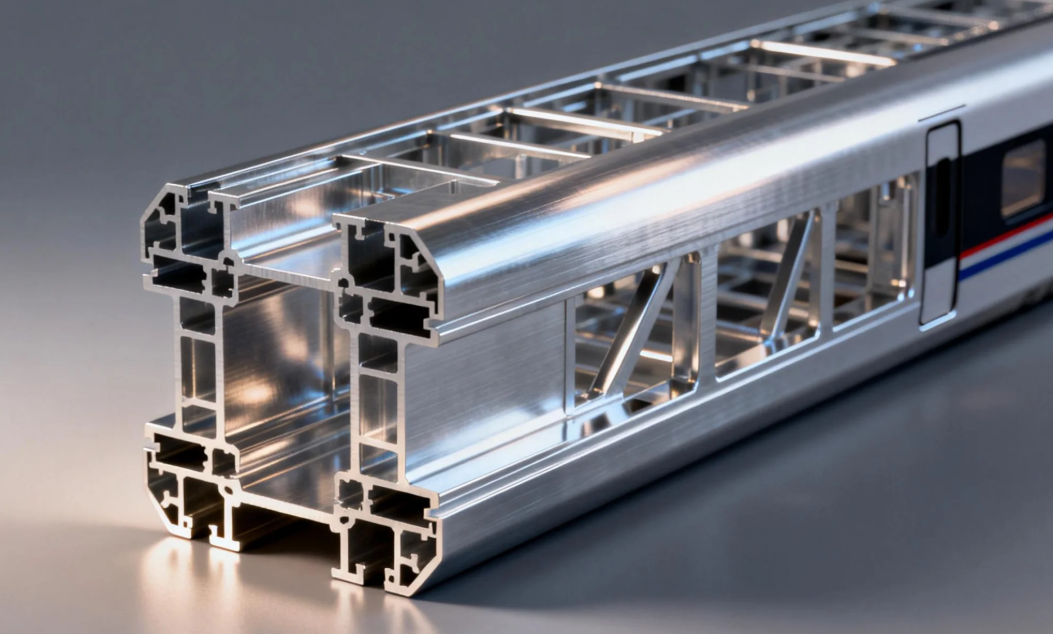

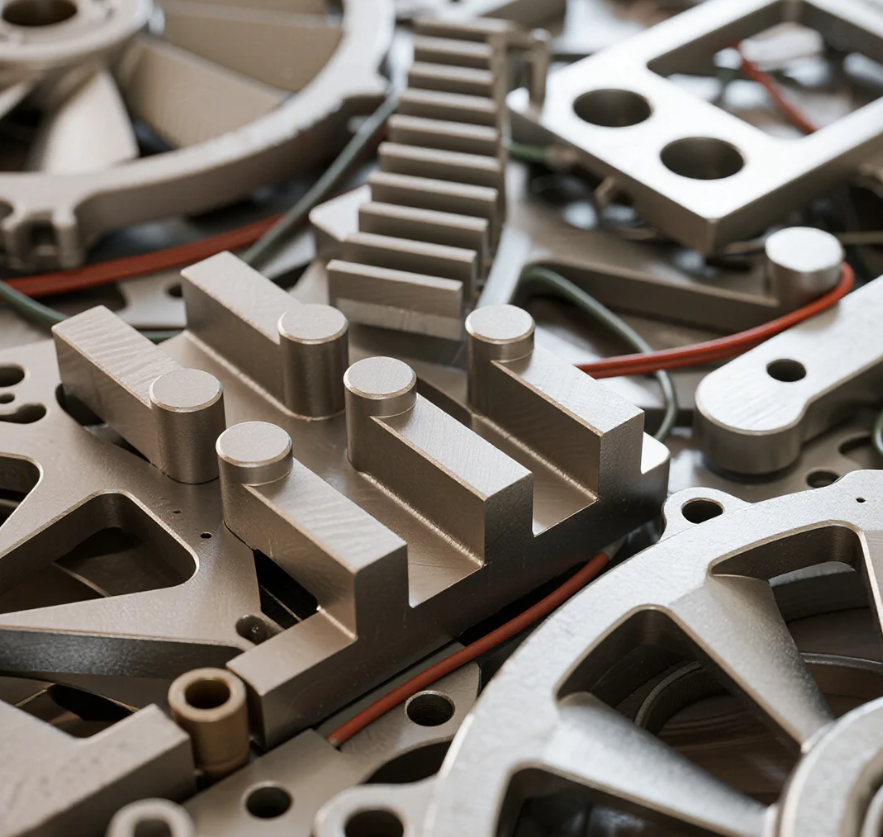

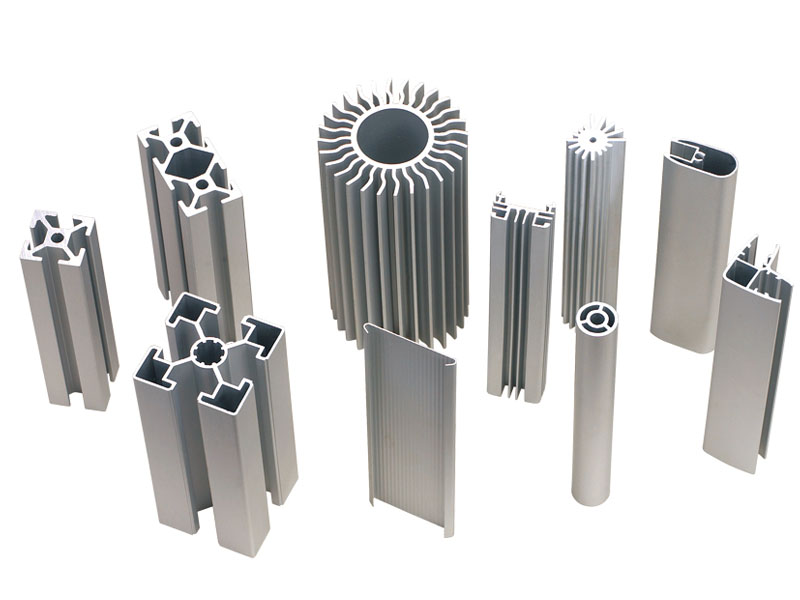

Heavy-duty storage support: The aluminium alloy columns and beams can bear heavy tableware and electrical appliances (such as built-in ovens), and will not deform over long-term use.

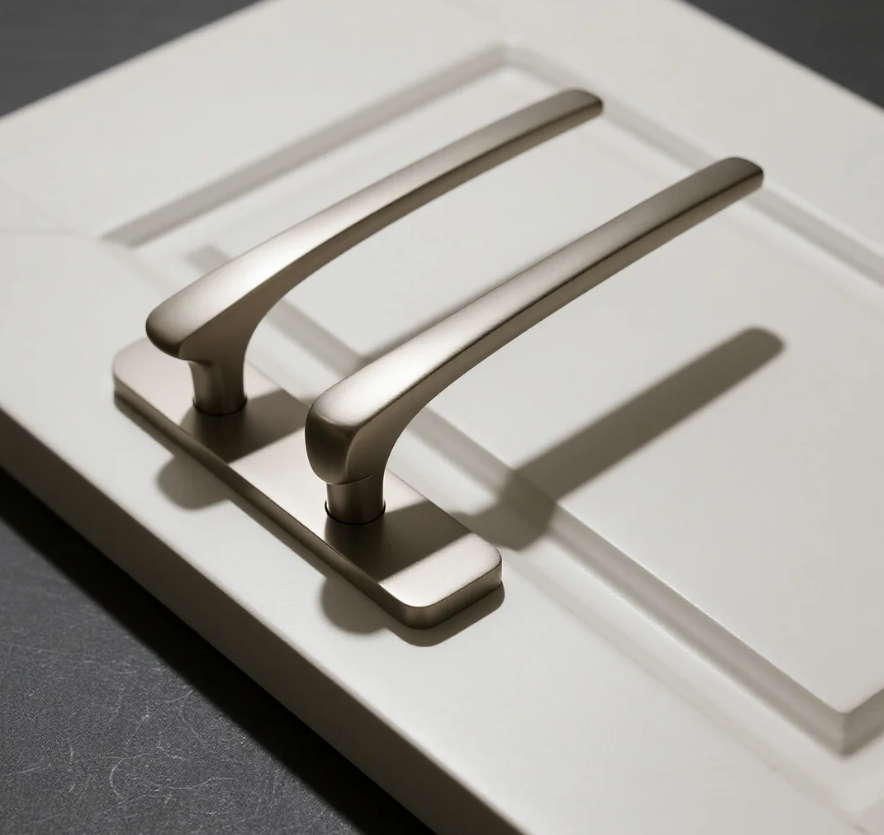

Hinge durability: Aluminium hinge bases are more resistant to repeated opening and closing than plastic or wooden substrates, thus extending the lifespan of hardware components.

Zero formaldehyde emission: Compared with artificial boards such as density board and particle board, aluminium profiles eliminate indoor pollution from the root.

Antibacterial property: The surface oxide layer inhibits bacterial growth and meets food contact safety standards (such as FDA certification)

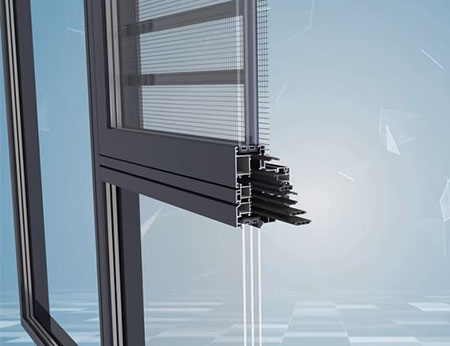

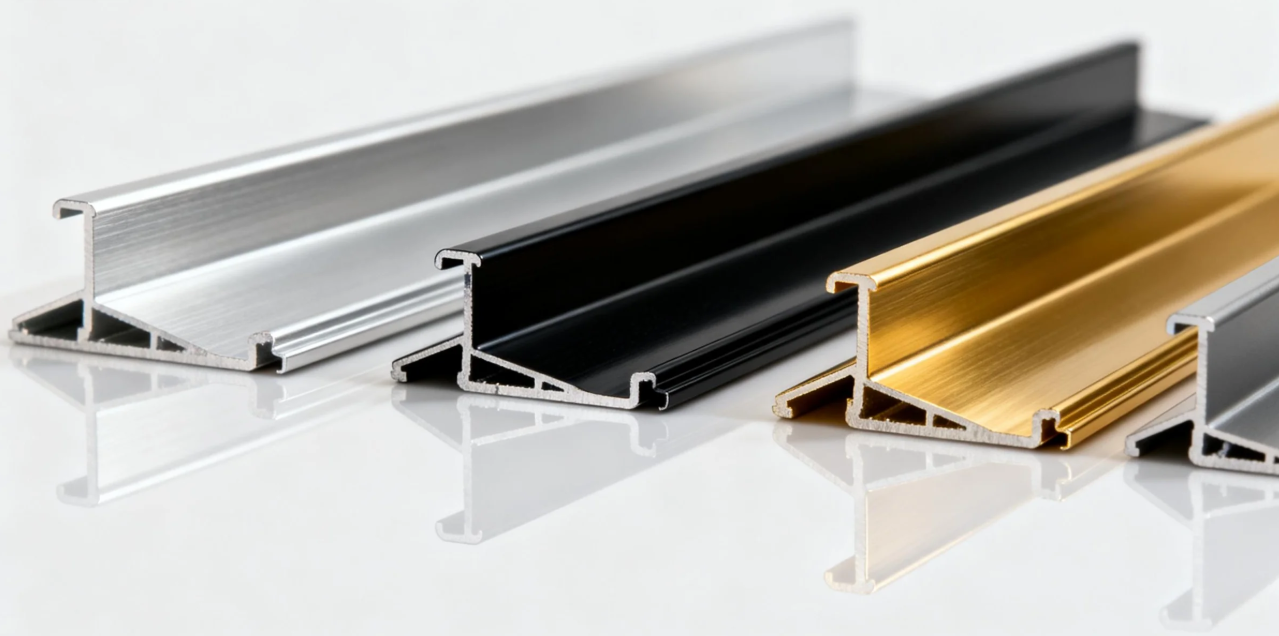

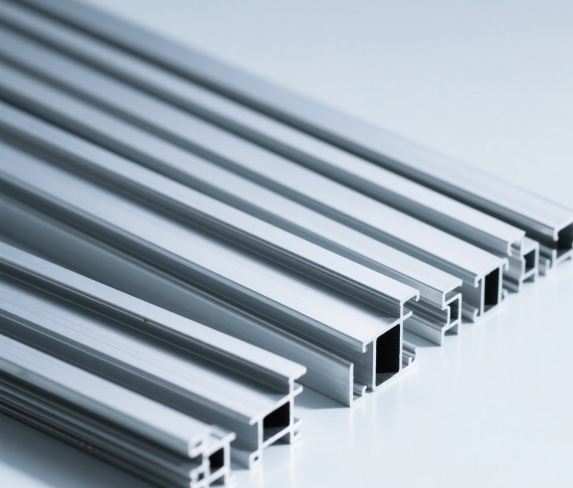

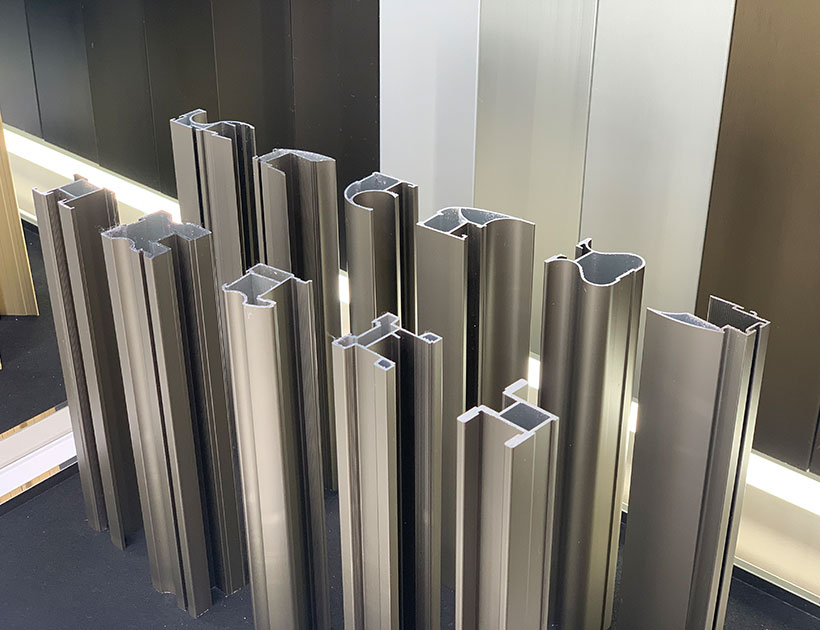

Narrow-edge process: Aluminium profiles can achieve ultra-thin frames (as thin as 1cm), and when paired with glass or acrylic door panels, they present a light and technological feel.

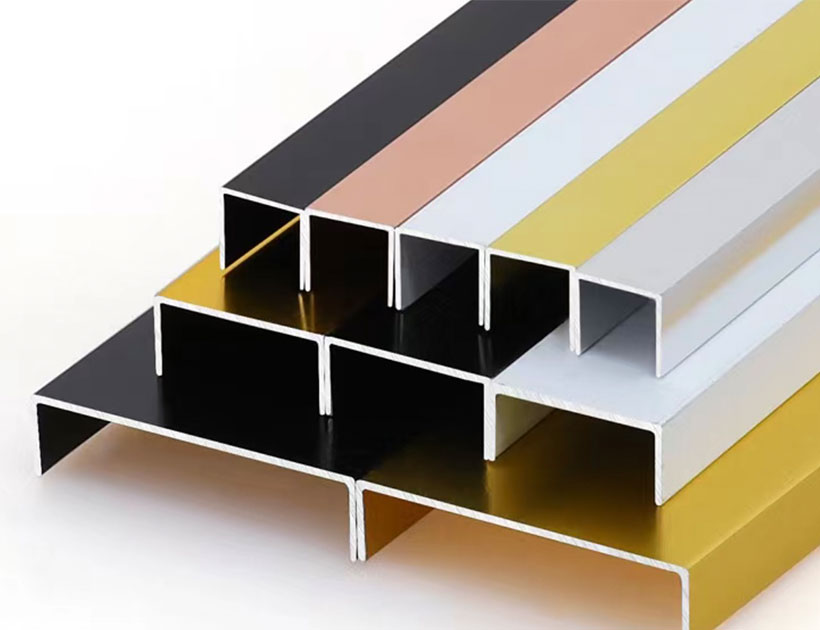

Color customization: Powder coating can match any color number, with common high-end textures such as matte black and champagne gold.

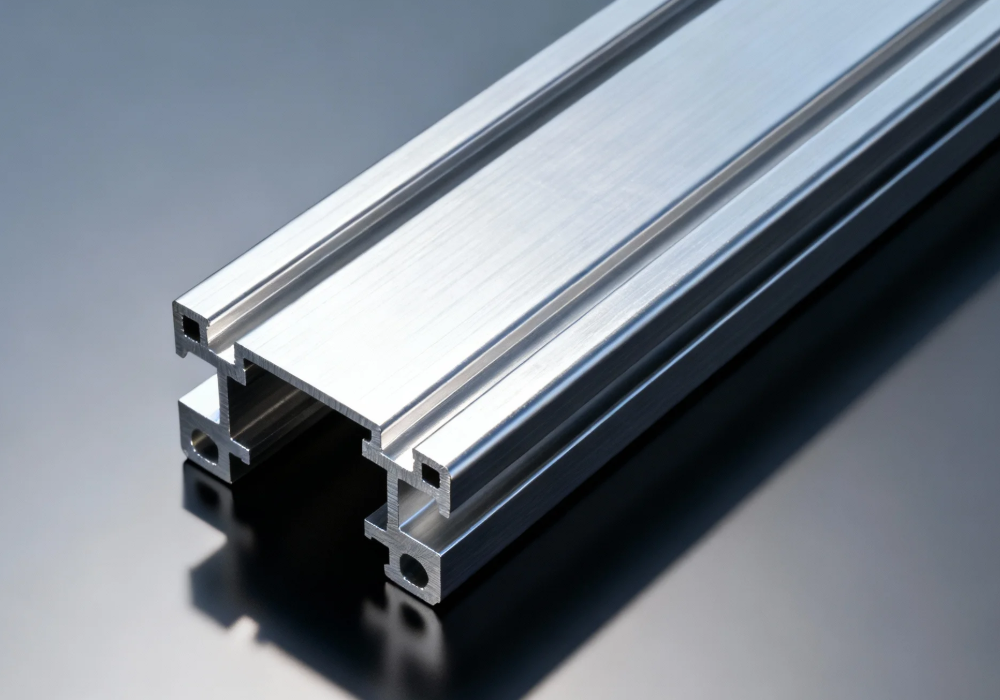

Welding-free structure: It uses corner codes and pins for connection, and the assembly efficiency is over 50% higher than that of traditional wooden cabinets.

Detachable design: Convenient for later layout adjustment or relocation and reorganization (suitable for renting and apartments)

Flame retardant property: The melting point reaches 660℃, making the cabinet around the stove safer and reducing the risk of fire.

Heat resistance test: The surface coating does not change color at 150℃ (better than PVC laminate).

Anti-oil stain: Smooth surfaces can be wiped clean immediately. Stubborn stains can be wiped with a cleaner without color seepage.

No coating peeling: The anodizing process is more wear-resistant than baking varnish and leaves no scratches after long-term use.

All-aluminium cabinets: Both the cabinet body and door panels are made of aluminium profiles, making them suitable for extremely humid areas or commercial kitchens.

Mixed materials: Aluminium frame+rock plate countertop/glass door panel, balancing cost and aesthetics.

Functional accessories: Aluminium pull-out baskets and slide rails, solving the load-bearing problem of drawers.

Sound insulation treatment: aluminum cabinet should be equipped with damping pad to reduce the collision noise of tableware.

Cost control: Pure aluminium cabinets are relatively expensive. It is recommended to use them in key areas.

Aluminium profile cabinets are the ideal choice for those pursuing zero formaldehyde, high durability and modern style, especially suitable for open kitchens, small-sized apartments (space-saving) and environmentally sensitive families. The cost performance can be further optimized through a mixed material design (such as aluminium frame+ wooden countertop).

The advantages of using aluminium alloy for the main structure of high-speed train carriages

Methods for distinguishing Indoor and Outdoor Aluminium Doors

Maintenance methods and tips for aluminium doors and windows

Characteristic of outward-opening and hung aluminium windows

Xinhe Aluminium Research: 7.14-7.18 Analysis of Aluminium Prices

Seven Benefits Of Using Aluminium Profiles In Curtain Wall Systems

The Application of Aluminium Profiles in New Energy Vehicles

The Composition and Application of Series 6 Aluminium Alloys

Top 5 Benefits of Using LED Aluminium Profiles in Modern Lighting

A Complete Guide to Aluminium Frame Profiles for Modern Structures

Exploring the Strength and Versatility of Aluminium Extrusion Profiles

How to Choose the Right Aluminium Profile Supplier for Your Project