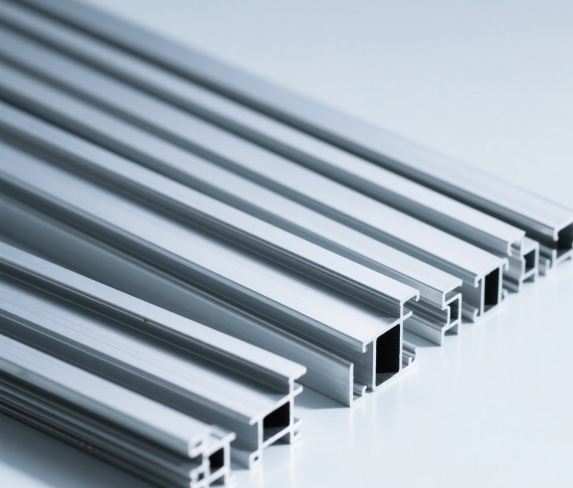

Aluminium profiles are strong, lightweight, and resistant to corrosion, and they are utilized extensively in many different sectors. Choosing the right aluminium profile supplier is of vital importance, as it will have a big impact on the success of your project. The following is a comprehensive guide introducing the factors to be considered when choosing the right supplier.

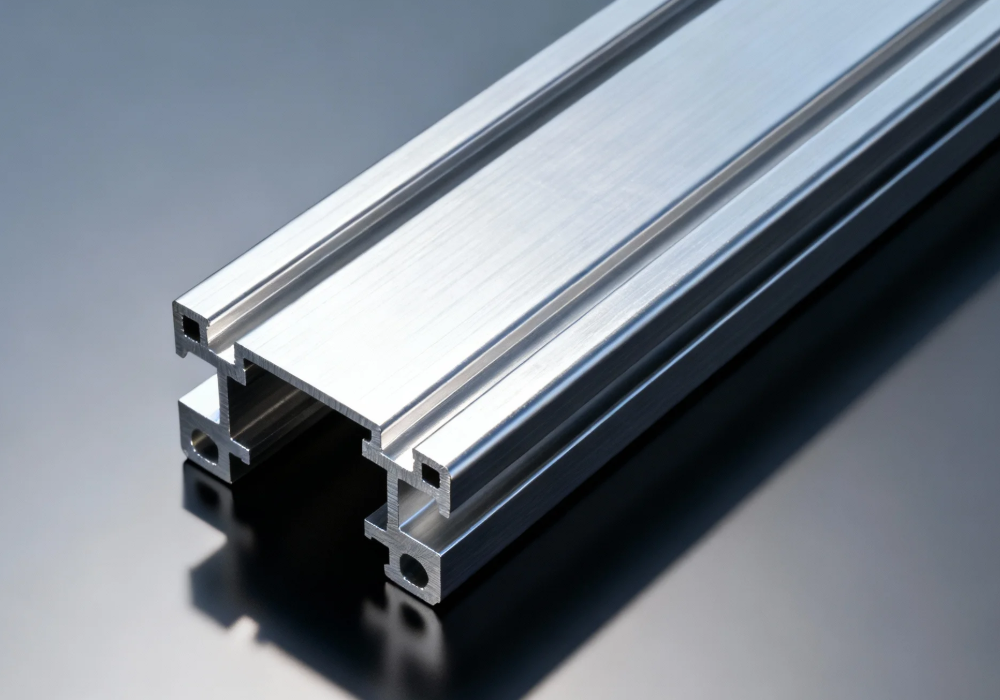

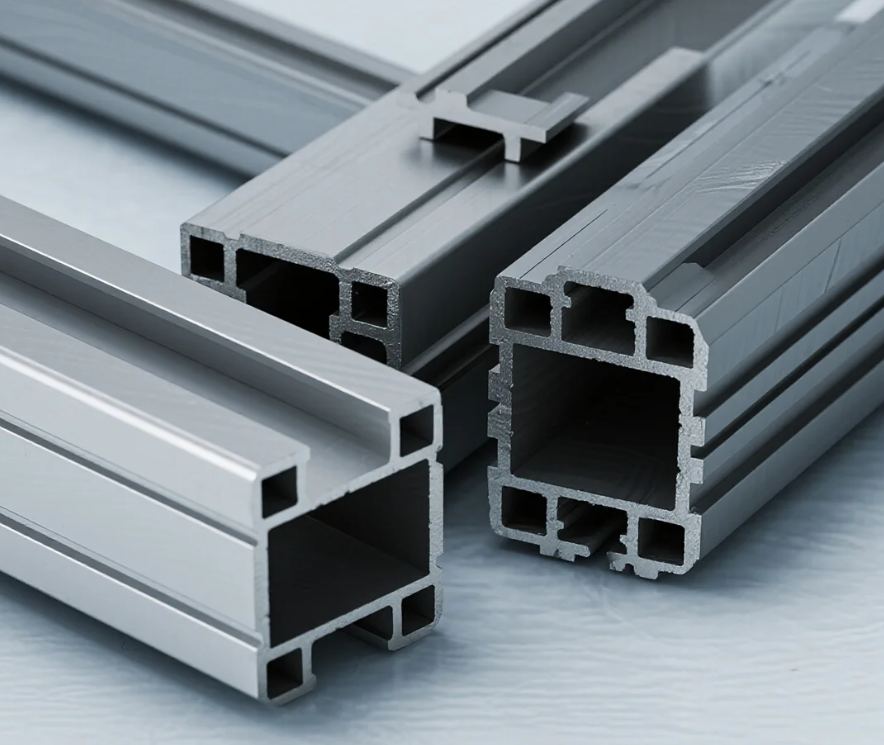

The quality of the product should be the main consideration when selecting an aluminium profile supplier. Profiles of superior quality must adhere to global standards like ISO, ASTM, or EN. These standards serve as crucial benchmarks for determining if the goods fulfill the requirements since they explicitly outline the composition, strength, dimensional accuracy, and surface treatment procedure of aluminium profiles.

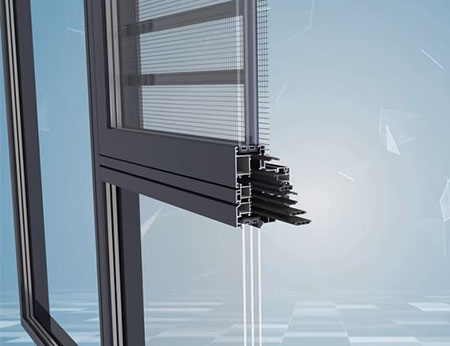

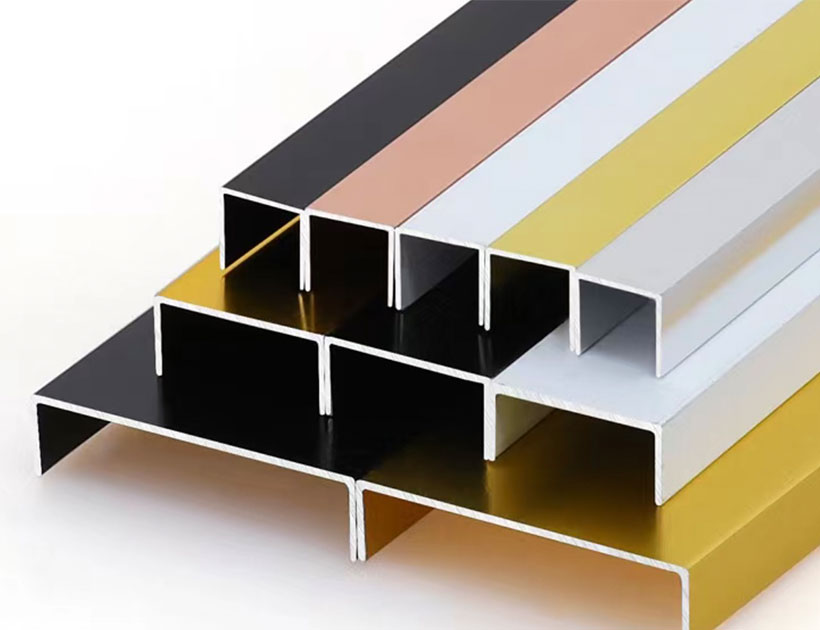

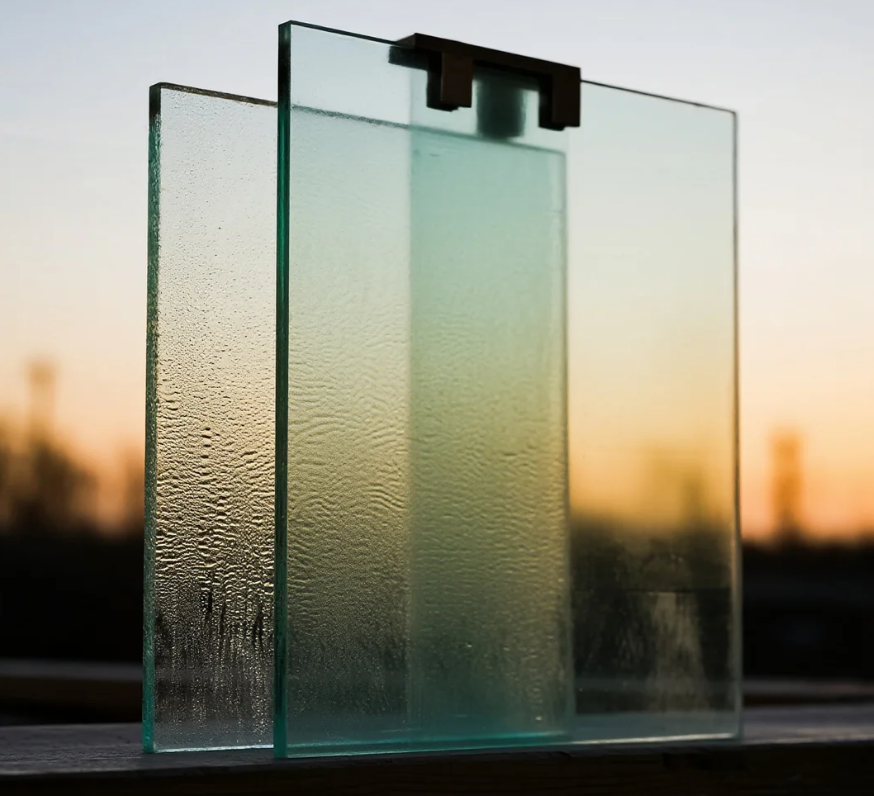

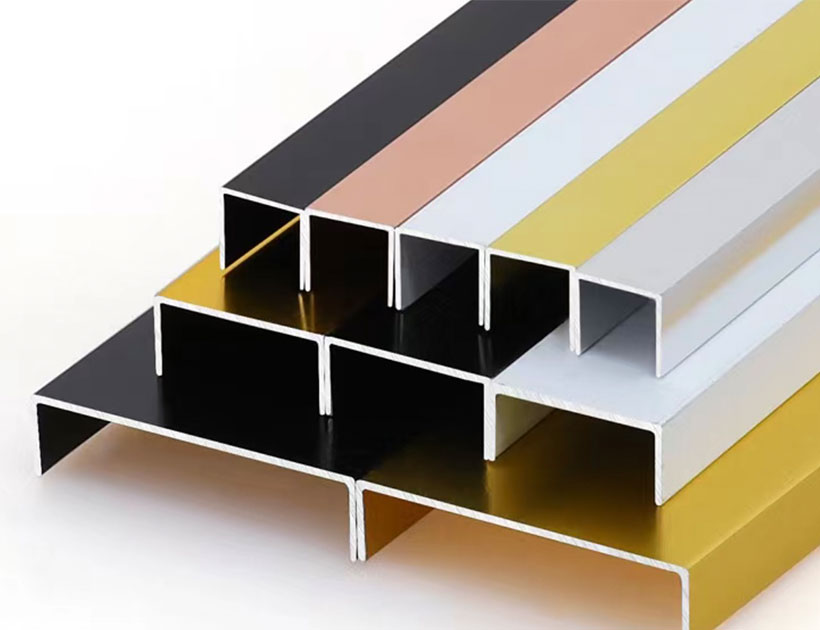

To guarantee the longevity and uniformity of the products, find out if they employ premium raw materials and cutting-edge extrusion technology. In order to improve corrosion resistance and appearance, reputable suppliers like Xinhe Aluminium will provide a range of surface treatment choices, including anodizing, electrophoretic coating, powder coating, etc.

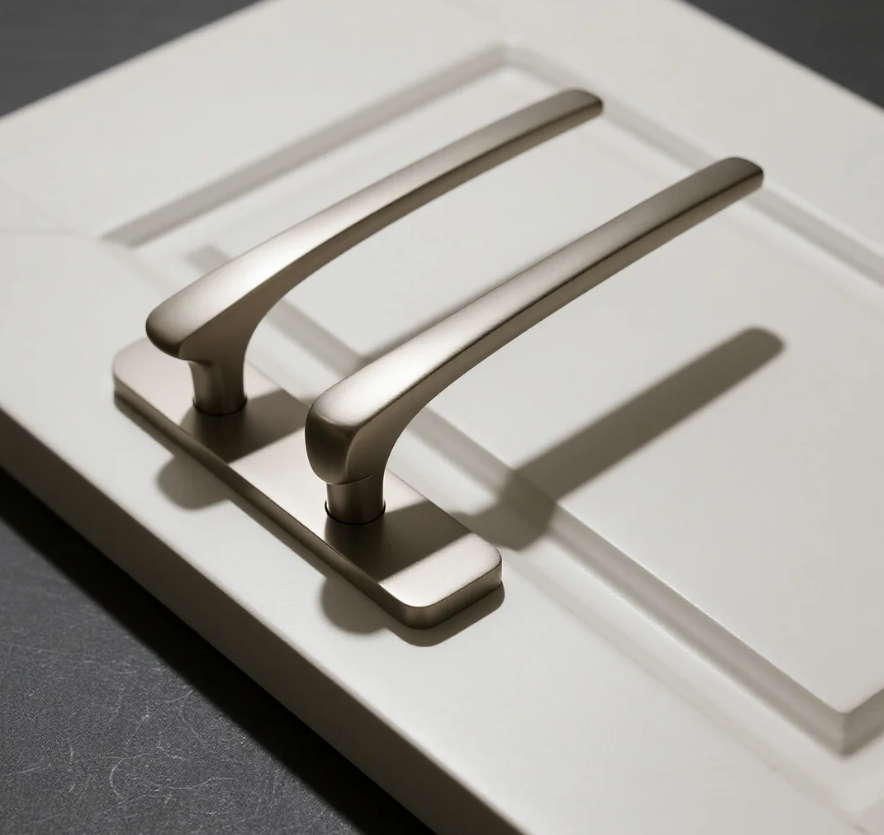

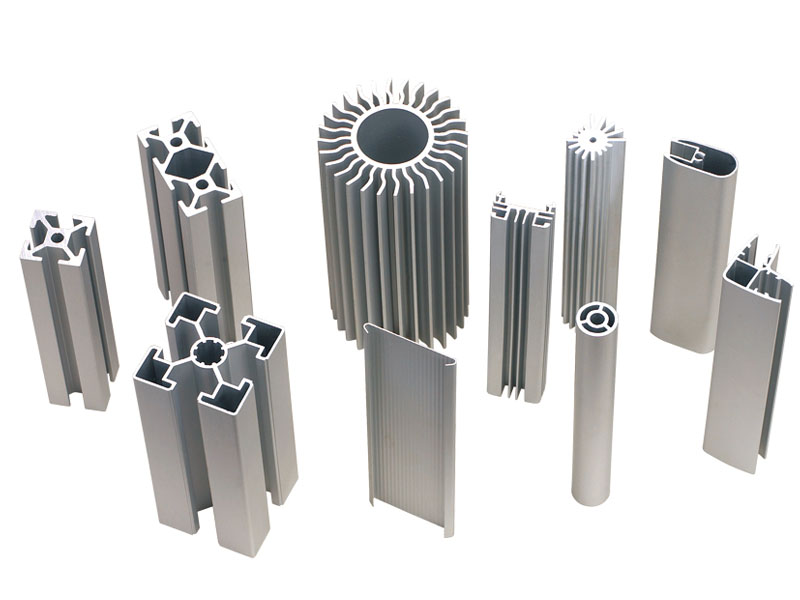

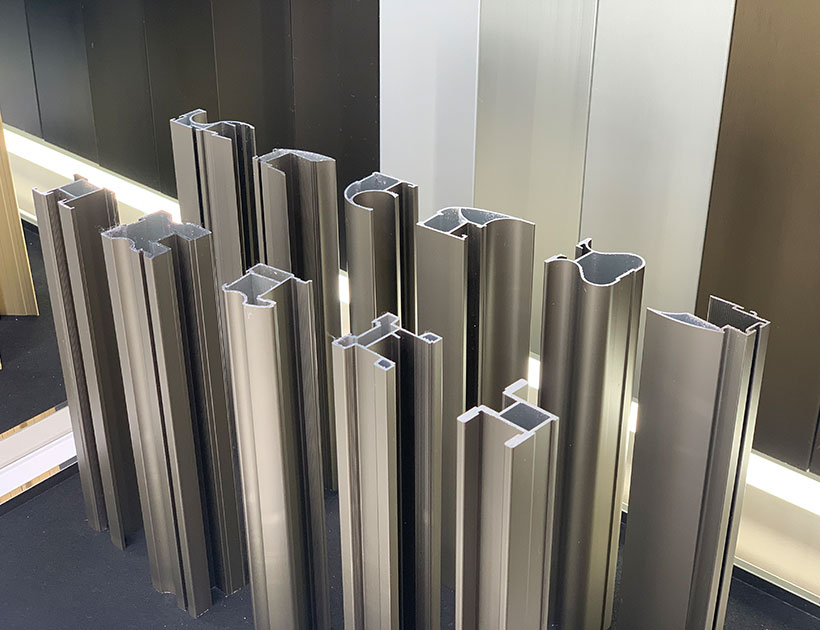

Every project has different needs. To satisfy various structural and aesthetic needs, a top supplier should provide a large range of profiles, including T-slot, angle, rectangular, and circular profiles.

More significantly, a top-notch supplier should be able to provide extrusion services that are specifically tailored to your design specifications. You can have more options from suppliers who can create custom aluminium profiles, regardless of whether you require particular sizes, forms, or surface treatments.

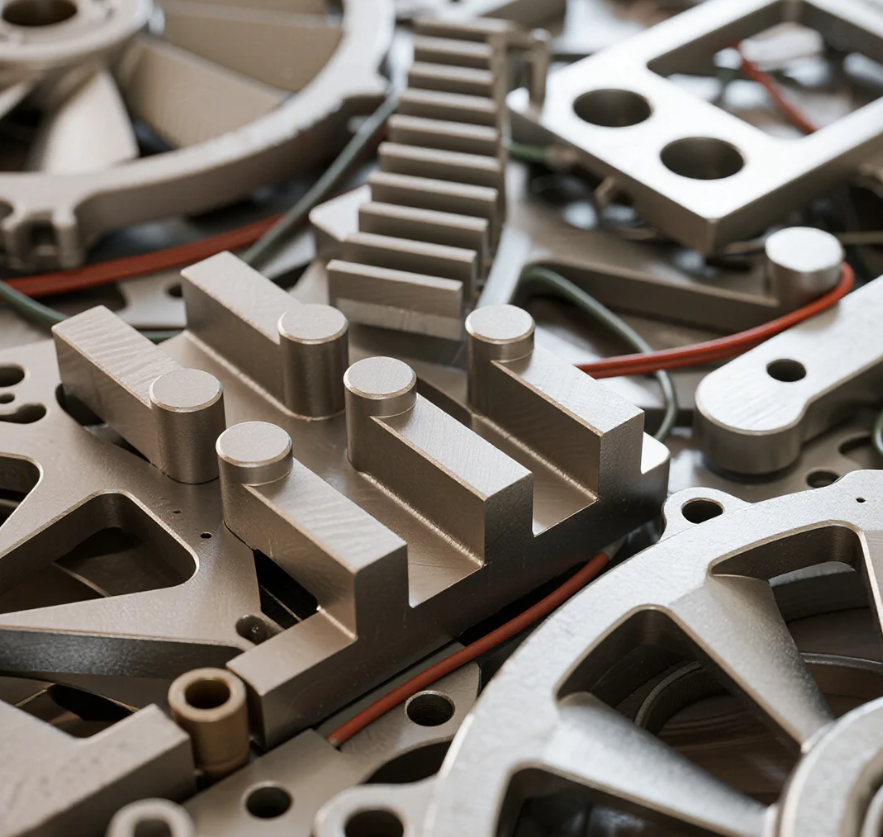

The experience of the supplier is another crucial factor to take into account when selecting an aluminium profile supplier. Due to years of operation and practice, suppliers with extensive industry expertise typically have refined their production procedures, quality control systems, and customer services, enabling them to deliver more reliable and superior products.

Furthermore, seasoned suppliers frequently have sophisticated production methods and quality control procedures that can preserve constant product quality throughout mass production and prevent issues brought on by erratic production or inadequate technology.

Timely delivery is of vital importance in project management. If the materials fail to arrive on time during the project, it may lead to costly delays, which in turn will affect the progress of the entire project. To avoid this situation, it is crucial to choose an aluminium profile supplier that can ensure continuous and timely delivery.

Understand their inventory levels, production capacity, and logistics support. Suppliers with strong supply chains and efficient delivery systems can help your projects proceed as planned.

An outstanding aluminium extrusion profile supplier should not only provide high-quality aluminium profile products, but also offer professional guidance and technical support at all stages of the project to help you achieve the best design and production results.

Experienced and highly qualified suppliers like Xinhe Aluminium can offer tailored recommendations based on your unique needs and suggest the right alloy type or production process, whether you’re selecting the type of aluminium profile alloy or determining the best manufacturing method. You will cut down on needless trial and error and modifications throughout the design and implementation process in this way.

Although cost is always important when choosing an aluminium profile supplier, the cheapest option is not necessarily the best. Price is frequently simply one aspect in evaluating suppliers. The entire value is what should be the main focus.

To guarantee that you are getting the best value for your money, you should thoroughly assess a number of factors when selecting an aluminium profile supplier, including material quality, customization possibilities, and service standards.

Choosing the right aluminium profile supplier is a key step to ensure the smooth progress of the project and achieve the expected goals. Quality, product range, reliability, service level, and other crucial aspects must all be carefully taken into account during this procedure. By carefully evaluating these factors, you will be able to establish partnerships with suppliers who can support your project goals, budget, and schedule, thereby ensuring the success of the project.

Methods for distinguishing Indoor and Outdoor Aluminium Doors

Maintenance methods and tips for aluminium doors and windows

Characteristic of outward-opening and hung aluminium windows

Xinhe Aluminium Research: 7.14-7.18 Analysis of Aluminium Prices

Seven Benefits Of Using Aluminium Profiles In Curtain Wall Systems

The Application of Aluminium Profiles in New Energy Vehicles

The Composition and Application of Series 6 Aluminium Alloys

Top 5 Benefits of Using LED Aluminium Profiles in Modern Lighting

A Complete Guide to Aluminium Frame Profiles for Modern Structures

Exploring the Strength and Versatility of Aluminium Extrusion Profiles