Aluminium extrusion profiles have completely transformed the way the industry designs and builds structures, products and systems. Their unique strength, lightness and adaptability make them the preferred choice in fields such as architecture, automotive, aerospace, electronics and interior design. With the continuous development of manufacturing demands, aluminium extruded profiles are more practical than ever before.

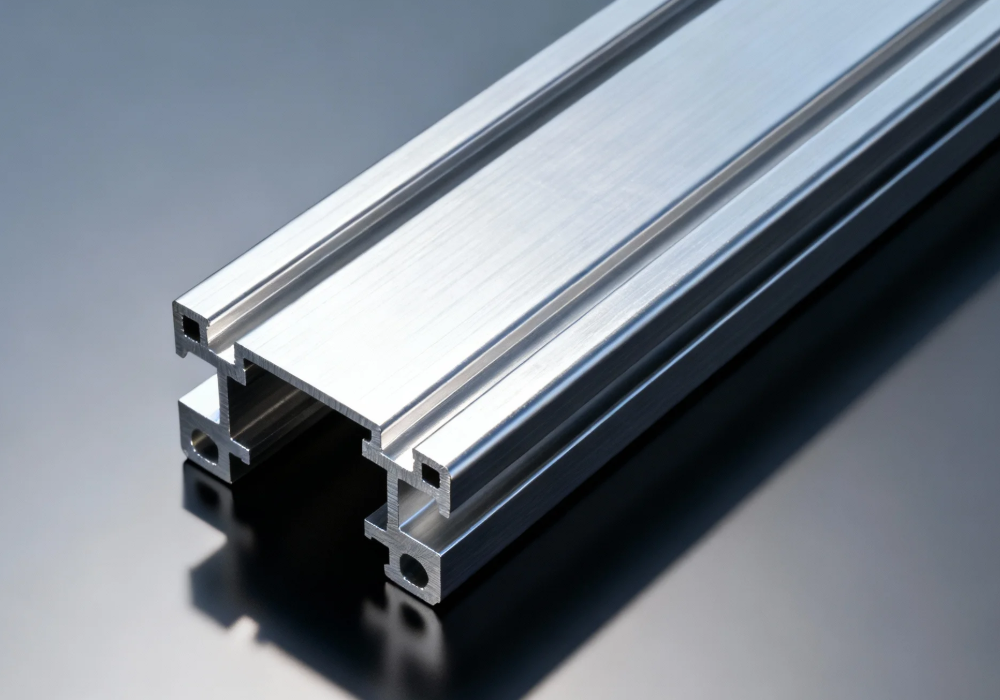

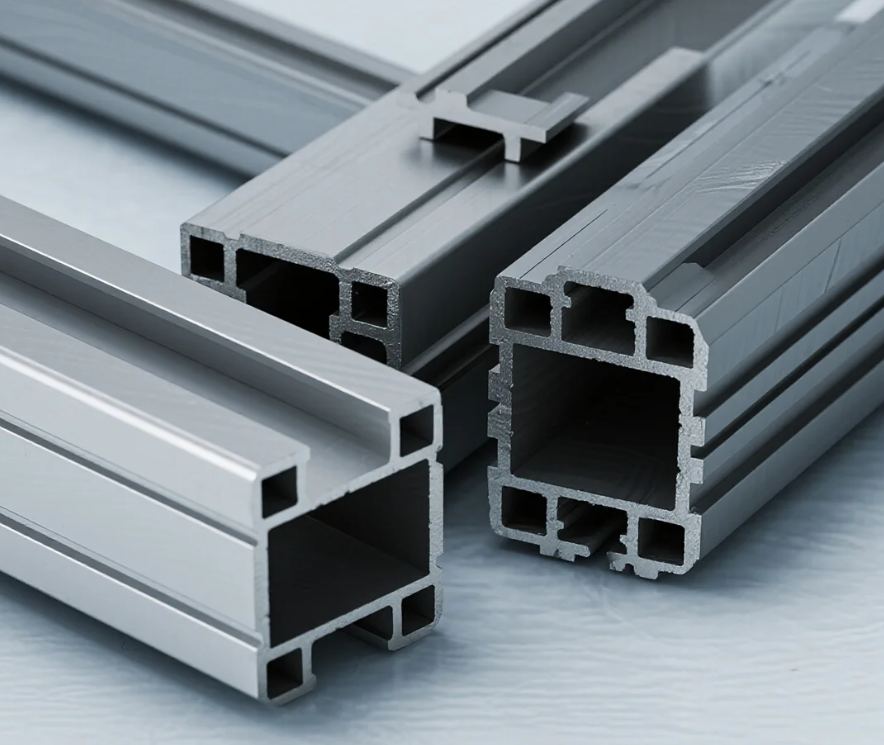

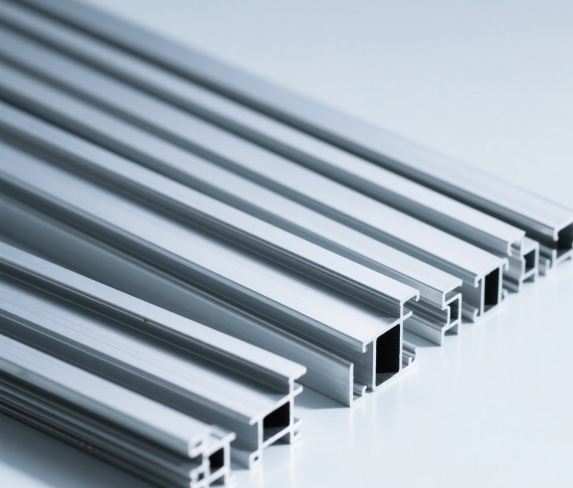

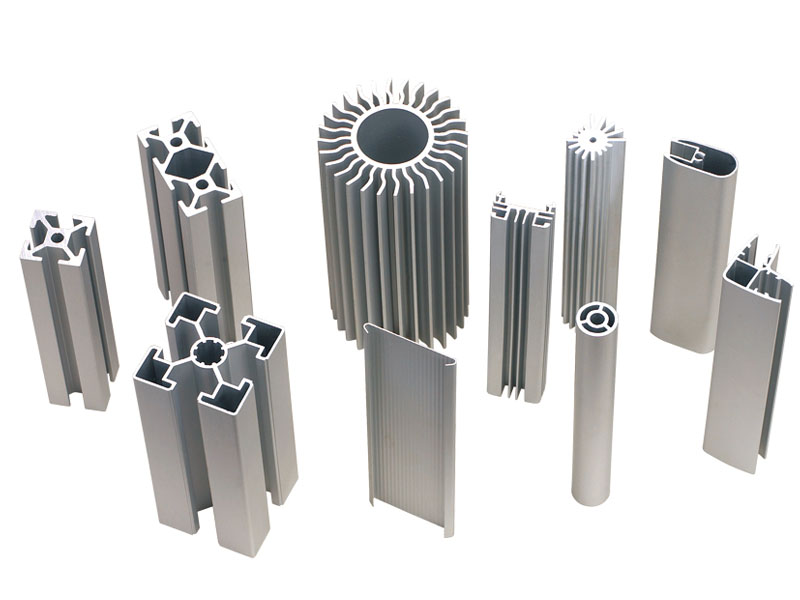

Aluminium extrusion is an efficient, sustainable and widely applicable metal forming process. It forms continuous profiles with fixed cross-sectional shapes by applying high pressure to preheated aluminium billets and pushing them through designed molds. This process enables the production of various aluminium profiles with different cross-sectional complexities, ranging from the most basic angle steel and round pipes to precision structural profiles with multiple chambers and multi-functional channels.

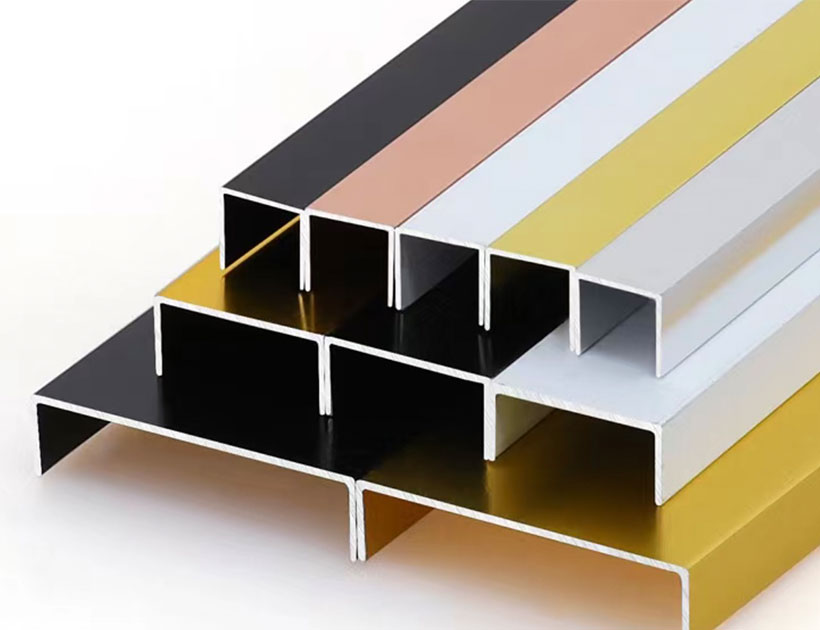

Aluminium extrusion profiles are typically made from 6000 series alloys such as 6061 or 6063, which achieve an excellent balance in terms of strength, corrosion resistance, and machinability. Aluminium profiles after extrusion molding usually require further surface treatments, such as anodizing, powder coating, or painting, etc., to enhance their aesthetic appeal and durability.

Although the density of aluminium is only one-third that of steel, it demonstrates an excellent strength-to-weight ratio through alloy strengthening and extrusion processes. This unique combination of properties makes aluminium extruded profiles stand out in a variety of industrial applications, especially in those fields that are sensitive to weight but do not want to sacrifice structural strength.

Aluminium also has natural corrosion resistance. The dense and hard oxide layer formed on its surface can effectively prevent further erosion by moisture, oxygen and other corrosive media. After undergoing anodic oxidation treatment, this protective layer will be further thickened, possessing higher anti-oxidation and anti-ultraviolet capabilities. This not only enhances weather resistance but also improves the overall aesthetic appeal.

Aluminium extrusion profiles have been widely used in many industries due to their outstanding versatility and adaptability. The extrusion process allows for almost unlimited customization. Whether it is standard shapes or complex geometries, they can be customized according to project requirements.

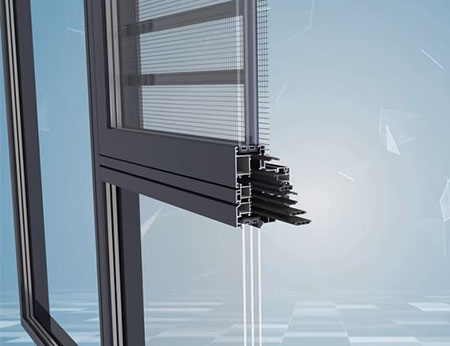

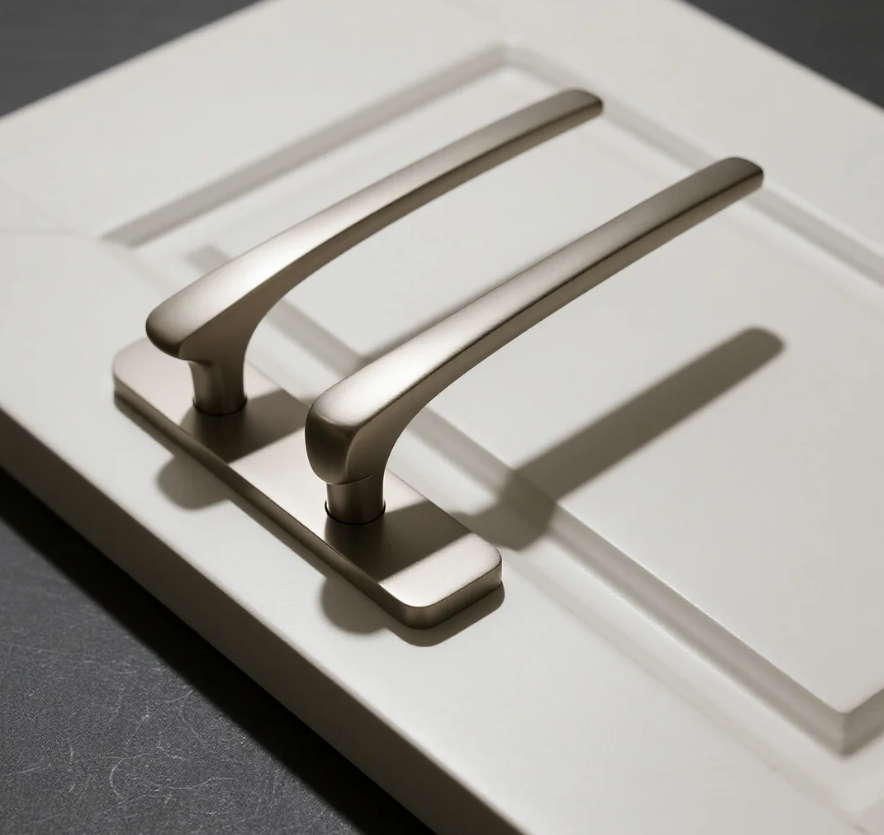

In the field of architecture, aluminium profiles are widely used in door and window frames, curtain wall systems, railings, etc. Aluminium extrusion profiles have a simple sense of lines and can be provided with a variety of color options through various surface treatment processes such as anodizing, electrophoretic coating, and spraying. Moreover, aluminium profiles are lightweight yet have high strength, making them particularly suitable for the design requirements of high-rise buildings and lightweight structures.

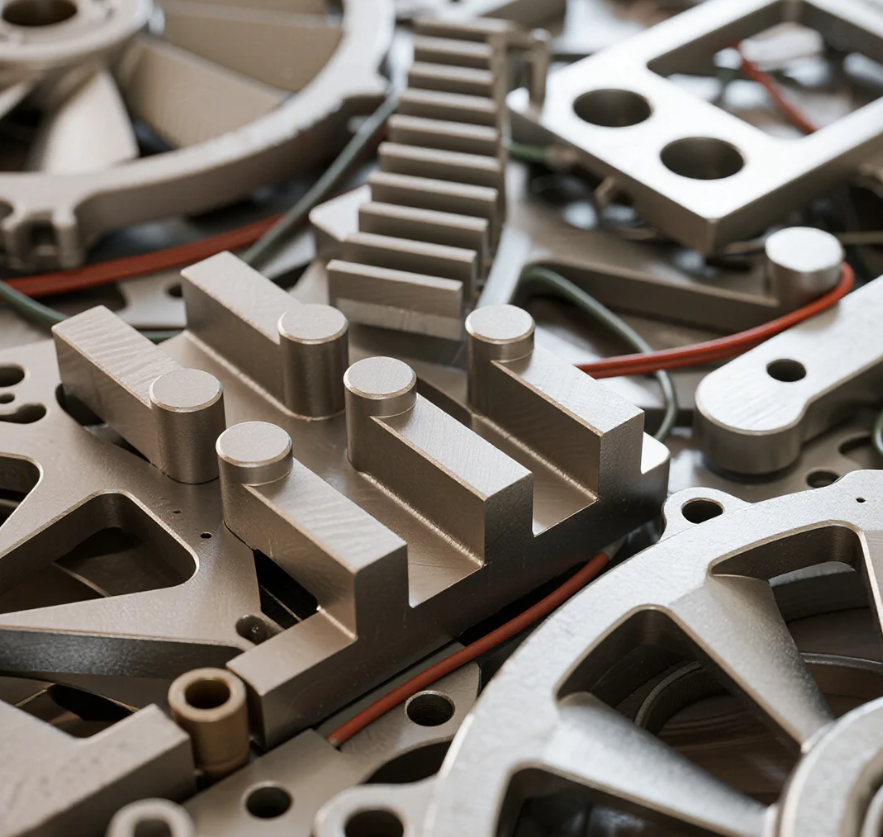

In the fields of industrial automation and robotics, T-slot aluminium profiles can be used to easily and efficiently build modular frame systems, workstations, housings, and conveyor structures. The T-slot structure makes modular assembly using standard connectors effortless, eliminating the need for welding and requiring almost no professional tools, thereby enhancing the flexibility of the overall project and the efficiency of later maintenance.

Aluminium extruded profiles have also shone brightly in the transportation industry. Customized profiles are widely used in everything from electric vehicles to interior decorative parts and structural components of trains. Their lightweight feature helps to reduce vehicle weight, improve acceleration performance, and fuel economy.

Aluminium extrusion profiles are not only structural components but also the key to innovation in many industries. Their high strength, light weight, and flexible design make them an excellent alternative to many traditional materials. As the demands for performance, efficiency and sustainability continue to grow, aluminium extruded profiles will remain the cornerstone of modern engineering and design.

Methods for distinguishing Indoor and Outdoor Aluminium Doors

Maintenance methods and tips for aluminium doors and windows

Characteristic of outward-opening and hung aluminium windows

Xinhe Aluminium Research: 7.14-7.18 Analysis of Aluminium Prices

Seven Benefits Of Using Aluminium Profiles In Curtain Wall Systems

The Application of Aluminium Profiles in New Energy Vehicles

The Composition and Application of Series 6 Aluminium Alloys

Top 5 Benefits of Using LED Aluminium Profiles in Modern Lighting

A Complete Guide to Aluminium Frame Profiles for Modern Structures

How to Choose the Right Aluminium Profile Supplier for Your Project