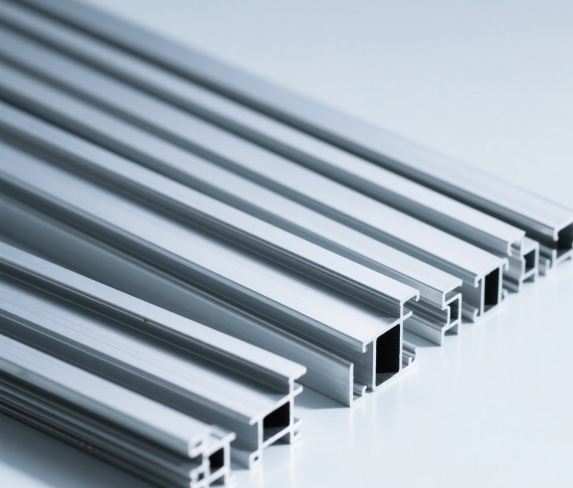

The need for specific materials and components is growing daily in a variety of industrial applications. Because of their exceptional strength, resistance to corrosion, and distinctive lightweight nature, aluminium materials are highly preferred. However, standard aluminium profiles frequently appear to be insufficient in extremely complicated or specialized applications. Custom industrial aluminium profiles are designed to provide solutions specifically tailored to meet the needs of various industries.

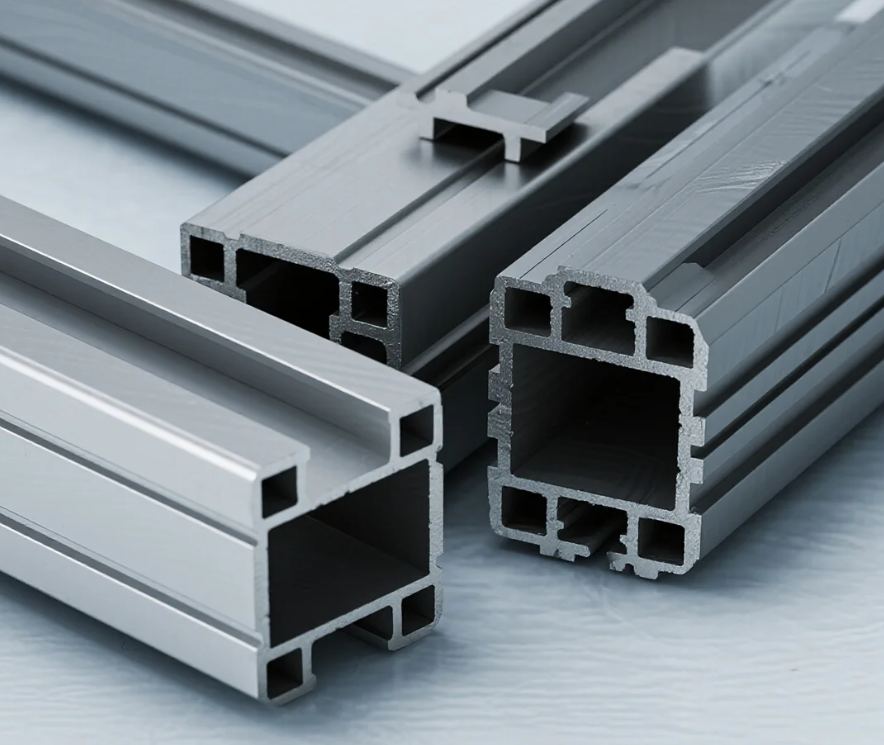

Custom aluminium profiles are made to satisfy certain project specifications. They are more adaptable in terms of size and shape than standard profiles, which are mass-produced and have set dimensions. Custom profiles are also more focused in terms of performance criteria, allowing them to better satisfy the demands of high strength, high precision, and unique usage settings.

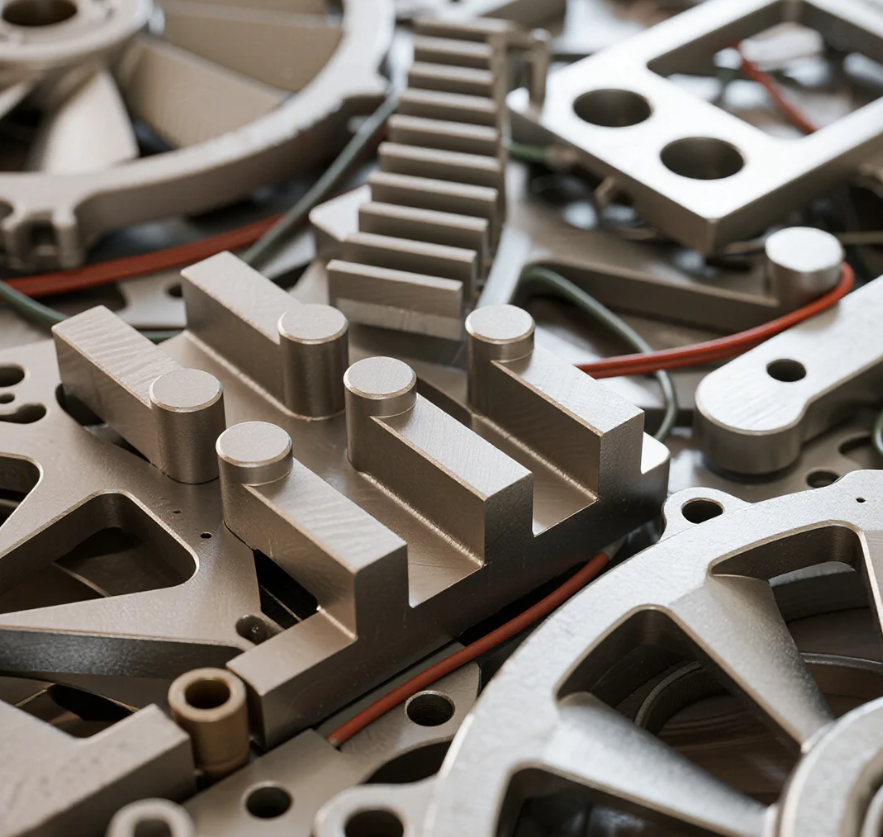

Depending on the need, important elements like load-bearing capability, exposure to the environment, and particular mechanical qualities needed for the application can be incorporated into the design. Because of their adaptability, custom aluminium extrusion profiles can be used to create anything from unique frameworks to mechanical components.

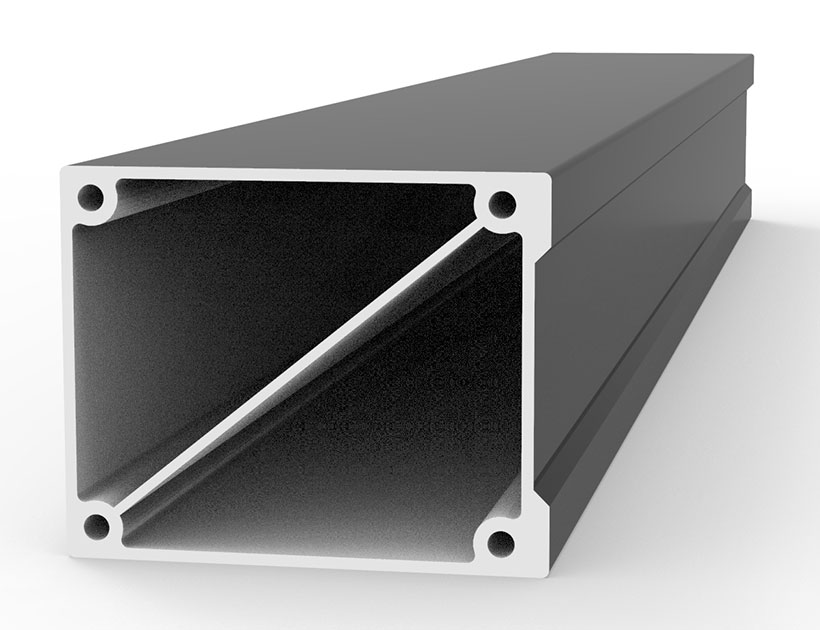

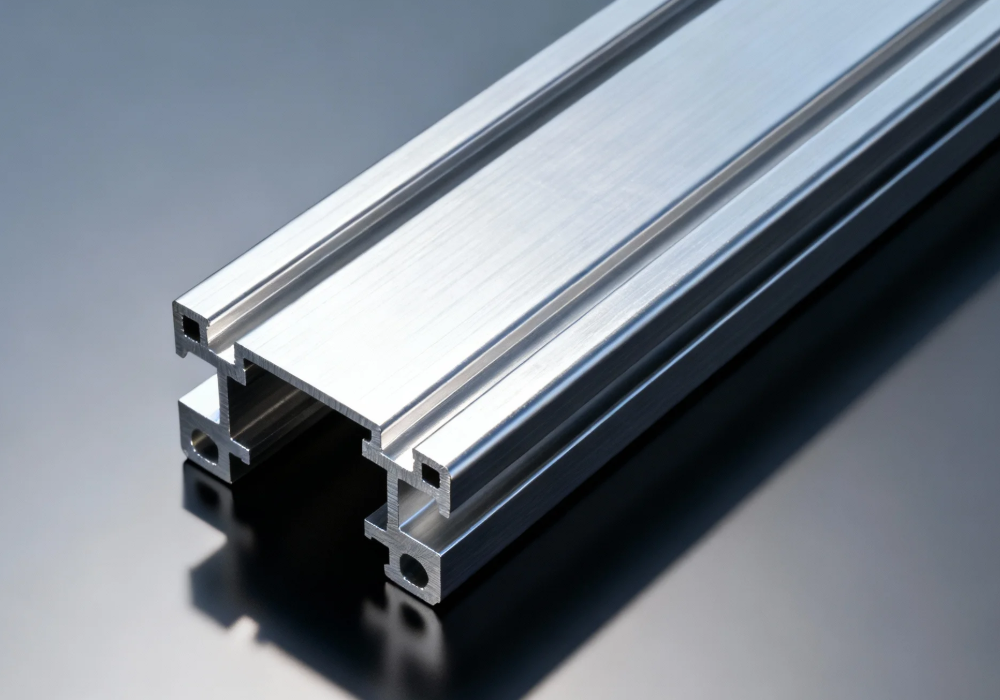

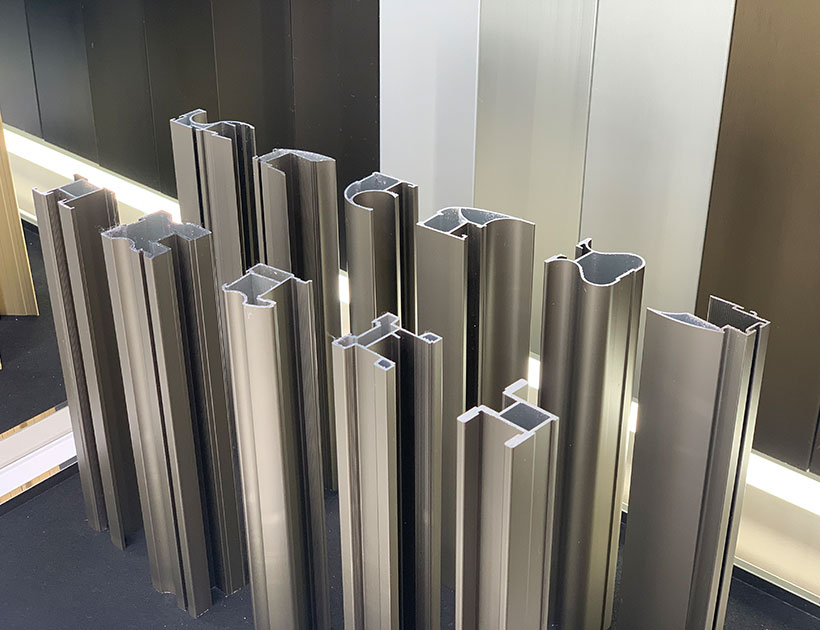

One of the most notable advantages of custom industrial aluminium profiles is their design flexibility. Since aluminium is a very machinable metal, it can be extruded into a wide range of sizes and forms to satisfy a variety of structural and functional needs.

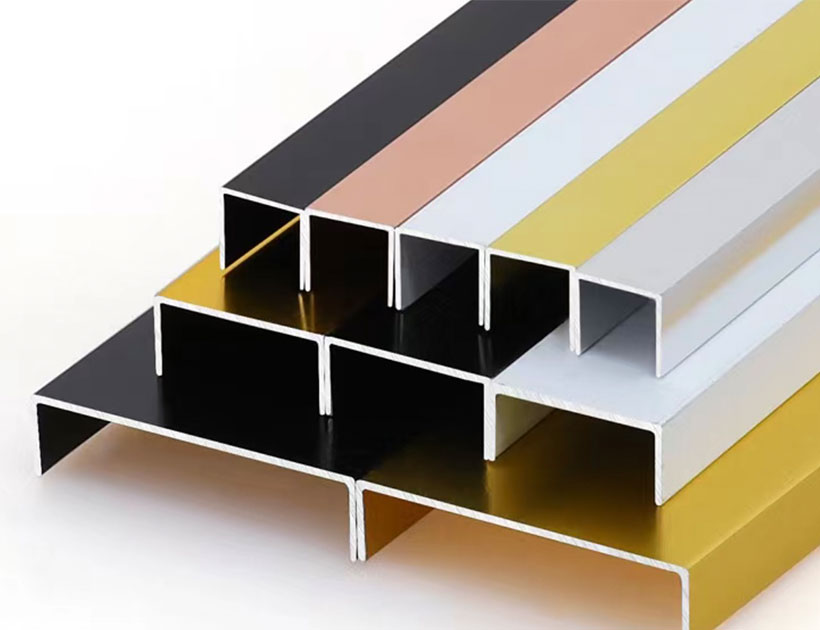

Whether it is simple channel steel, hollow tubes, or more complex designs, custom profiles can create profiles with complex cross-sectional shapes. This flexibility is not only reflected in the geometric shape, but also in multiple aspects such as wall thickness control, opening position, and surface treatment requirements.

An important part of the customizing process is selecting the right aluminium alloy. Properties like increased strength, resistance to corrosion, or electrical conductivity vary throughout alloys. For industrial profiles, 6060, 6061, and 6063 are often utilized alloys. Depending on the application, each alloy has unique benefits.

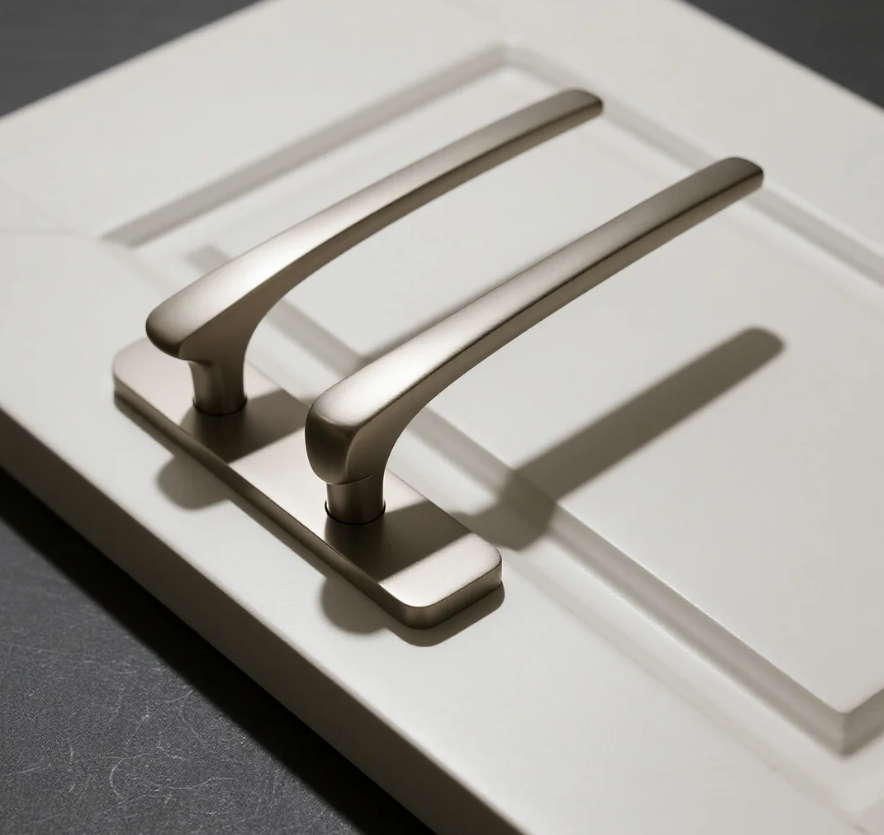

In addition to the alloy itself, custom industrial aluminium profiles can also adopt various surface treatments, including anodizing, powder coating, electroplating, etc., to enhance their strength and appearance. These treatments not only ensure that the profiles are fully functional, but also can resist environmental factors such as ultraviolet radiation, chemicals, and extreme weather conditions.

Custom industrial aluminium profiles can be relatively expensive to design and manufacture initially, but over time, their performance advantages and economic benefits greatly outweigh the initial outlay, making them a more cost-effective option for many projects.

For instance, highly compatible custom designs can significantly enhance assembly efficiency and structural integrity, reducing the need for post-processing, welding, and the use of connectors. Additionally, throughout the design phase, custom profiles optimize their sizes and forms based on their intended applications, avoiding excessive scraps and unnecessary processing steps from the source.

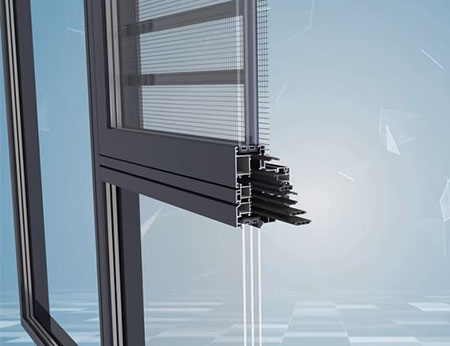

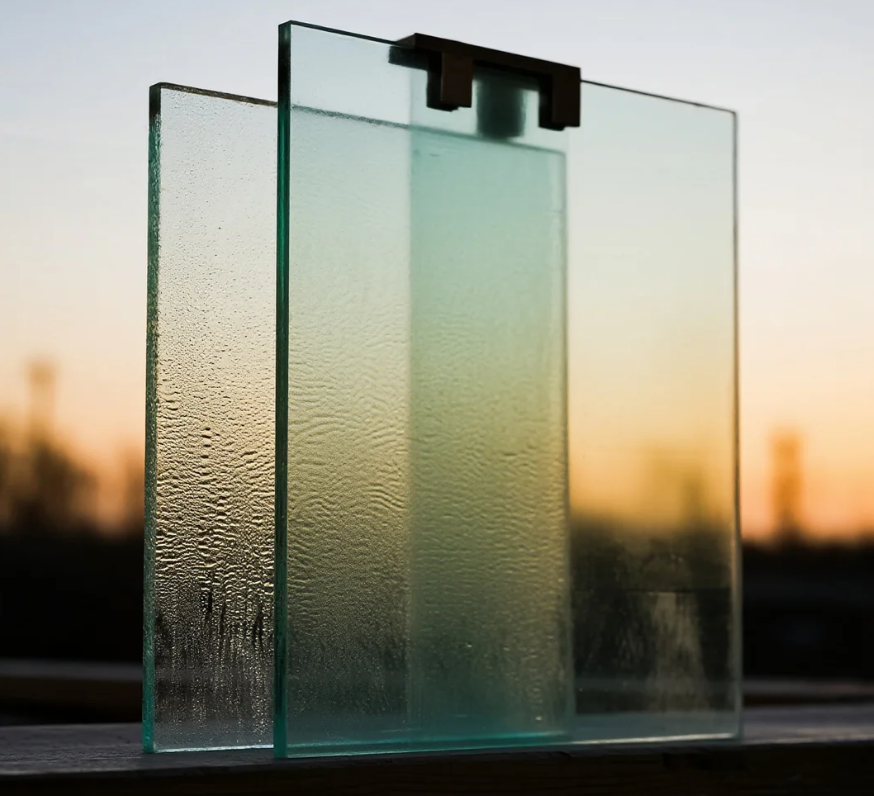

Custom industrial aluminium profiles are widely used in various industries. They are utilized in architecture for structural supports, curtain wall systems, and window frames. In the automotive industry, they are also used in body panels, chassis and other parts that need to be strong and lightweight. Custom profiles are also widely used in the casings and heatsinks of electronic products.

In addition, as custom aluminium extruded profiles can meet strict standards for strength, precision, and durability, they are also applied in industries such as aerospace, medical care, and transportation, including satellite brackets, aircraft connectors, surgical equipment frames, etc.

Custom industrial aluminium profiles are now an essential material for all spheres of life due to their adaptability, versatility, and capacity to be tailored to the particular requirements of a project. As the demand for specialized and high-performance solutions continues to grow, custom aluminium extrusions will continue to play a key role in shaping the future of industrial design and manufacturing.

Methods for distinguishing Indoor and Outdoor Aluminium Doors

Maintenance methods and tips for aluminium doors and windows

Characteristic of outward-opening and hung aluminium windows

Xinhe Aluminium Research: 7.14-7.18 Analysis of Aluminium Prices

Seven Benefits Of Using Aluminium Profiles In Curtain Wall Systems

The Application of Aluminium Profiles in New Energy Vehicles

The Composition and Application of Series 6 Aluminium Alloys

Top 5 Benefits of Using LED Aluminium Profiles in Modern Lighting

A Complete Guide to Aluminium Frame Profiles for Modern Structures

Exploring the Strength and Versatility of Aluminium Extrusion Profiles

How to Choose the Right Aluminium Profile Supplier for Your Project