Fluorocarbon spraying is a high-performance surface treatment technology, especially widely used in fields with extremely high requirements for durability and appearance, such as building curtain walls, aluminium doors and windows, and landmark buildings. The core of it is to use fluorocarbon coatings with polyvinylidene fluoride resin as the main component. The following is a detailed elaboration of its core performance:

Outstanding weather resistance

Performance: This is the most prominent advantage of fluorocarbon coatings. It can effectively resist the erosion of harsh climatic conditions such as ultraviolet rays, humidity, temperature changes, acid rain and salt spray.

Principle: The F-C chemical bond is one of the strongest molecular bonds known, with extremely high bond energy and a very stable structure, making it difficult to be damaged by ultraviolet rays. This makes the coating not easy to powder, lose light and change color.

Data: High-quality fluorocarbon spray coatings can ensure that there is no severe powdering or fading (color change ΔE<5) for 20 to 30 years. It is far superior to ordinary powder coating or acrylic coating.

Excellent corrosion resistance and chemical stability

Performance: It has excellent resistance to most chemicals, solvents and cleaning agents. It can effectively prevent the corrosion of the aluminium substrate by industrial waste gas, acid rain and slat from sea breeze.

Application: It is particularly suitable for coastal areas, industrial cities and other corrosive environments.

Excellent self-cleaning property

Performance: The surface of the coating is smooth and not easy to adhere to dust and pollutants. Even if it adheres, it can be easily washed away by rain, keeping the building;s appearance clean for a long time and reducing maintenance costs.

Principle: Fluorocarbon materials have extremely low surface properties and hydrophobicity, making it difficult for water and oil stains to penetrate and adhere.

Good mechanical properties

Adhesion: It adheres very firmly to the surface of aluminium materials that have undergone good pretreatment (such as chromate) and is not easy to peel off.

Flexibility: It can withstand varying degrees of bending and stretching without cracking (such as passing the T-bend test).

Wear resistance: The surface hardness is relatively high, which can resist certain friction and scratches.

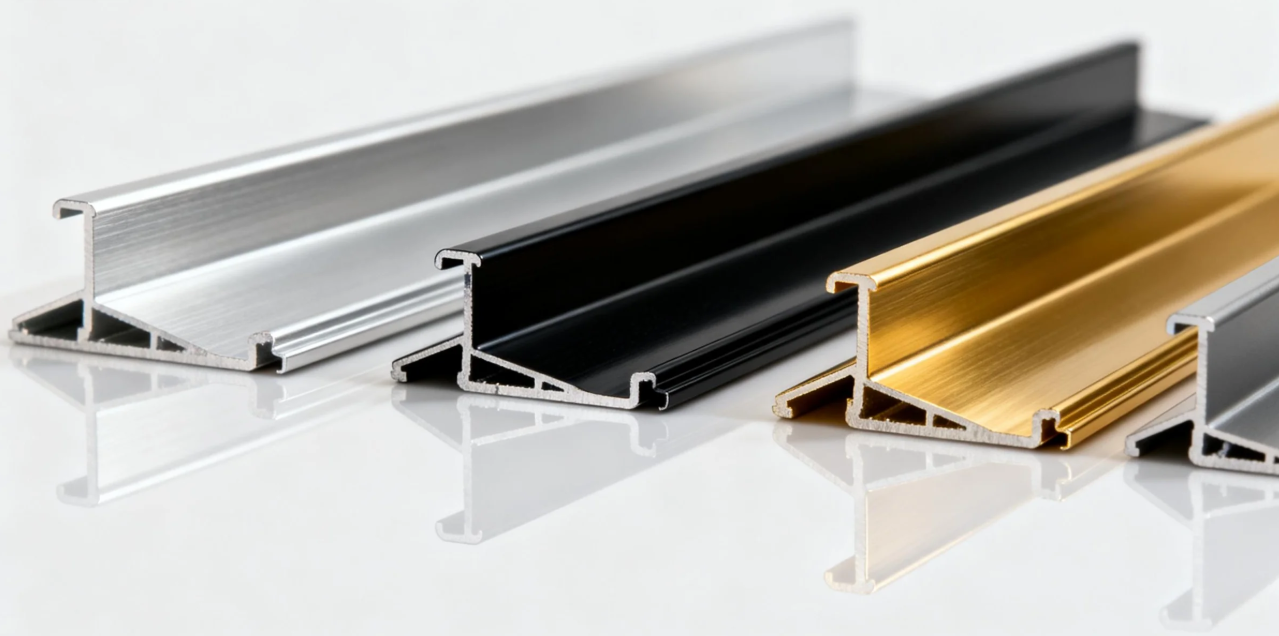

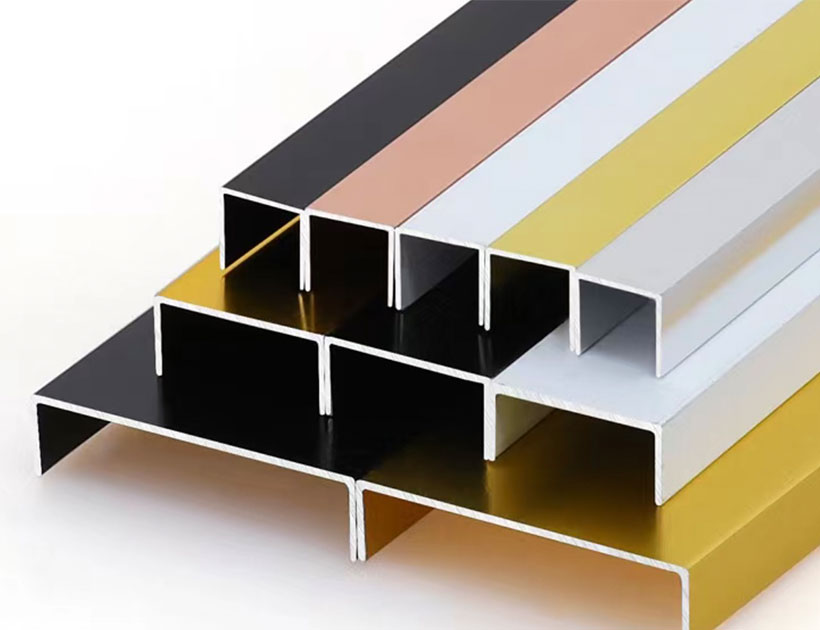

Rich decoative properties

Color: It can be mixed into various clors, including metallic colors, pearlescent colors, special effect colors,etc., to meet the aesthetic needs of different architectural designs.

Texture: Different gloss levels such as high gloss and matte are avaliable for selection.

To ensure quality, the performance of fluorocarbon-coated aluminium profiles usually needs to comply with a series of strict international and domestic standards. Common test items include:

Weather resistance test–QUV accelerated againg test: Simulating the damage caused by ultraviolet rays and water vapor, it usually requires no bubbling, peeling, or powdering for more than 4000 hours, and a color difference ΔE<2.0.

Xenon lamp aging test–Simulating full-specturm sunlight, with more comprehensive test conditions.

Natural exposure test: Long-term field tests are conducted in specific locations (such as Florida, Hainan), and the data is the most genuine and reliable.

Chemical corrosion resistance test— Salt spray resistance test: Generally, it is required to pass the 4000-hour neutral salt spray test (NSS Test) without any corrosion phenomenon. This is the core indicator for measuring the anti-corrosion ability.

Acid and alkali resistance test: Immerse in acid or alkali solutions of specific concentrations and observe the changes.

Mechanical property testing–Adhesion test: Commonly used grid method (grade 0 or 1 is the best)

Hardness test: Common pencil hardness (usually required to be ≥H or higher)

Impact resistance: Conduct forward and reverse impact tests to check if the coating cracks or peels off.

Common standards: AAMA 2605 of the United States and GB/T 5237.5 of China are authoritative standards for fluorocarbon-coated aluminium profiles used in construction. Among them, AAMA 2605 is recognized as a high-performance specification in the industry.

Excellent performance not only comes from the coating itself, but also depends on strict construction techniques.

Pretreatment: Degreasing and chemical conversion (sucha s chromate or zirconium conversion) to form a base layer that enhances adhesion and corrosion resistance.

Spraying: Multi-layer spraying (usually two coats and one bake or three coats and one bake: primer, color paint, and clear coat).

Solidify: The resin is fully cross-linked and cured in a high-temperature baking oven (typically≥230°C) to form a dense and stable coating.

| Characteristics | PVDF | PE | Acrylic spray |

| Weather resistance | Excellent (20-30 years) | Good (5-10 years) | General |

| Chemical resistance | Excellent | Good | General |

| Mechanical properties | Excellent | Excellent (Good adhesion) | General |

| Color diversity | Abundance | Very rich | General |

| Cost | High | Medium | Lower |

| Application | High-end curtain walls, landmark buildings | Doors and windows, interior and exterior decoration | Gradually being replaced |

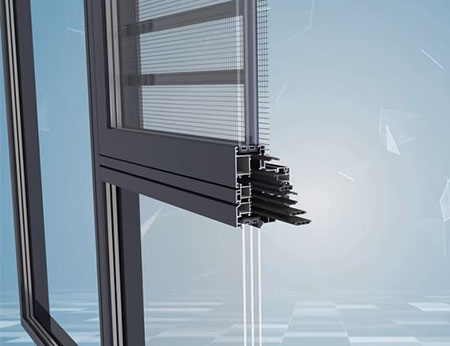

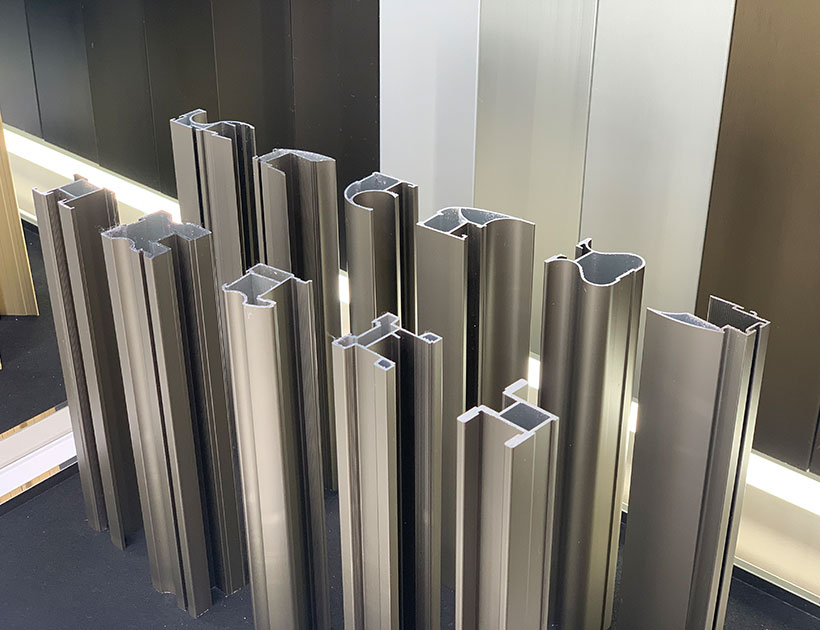

High-rise building curtain walls– This is its most important application field.

Large public facilities such as airports, stadiums and theaters.

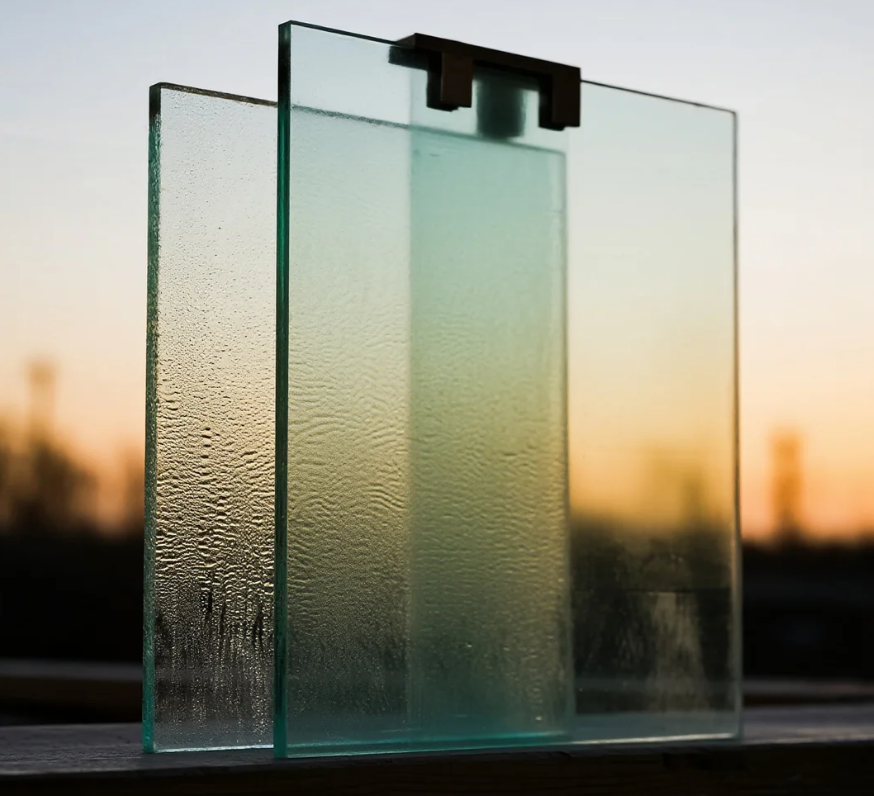

High-end aluminium doors and windows and unitized curtain walls.

Transportation facilities: such as subway stations and high-speed railway stations.

Fluorocarbon-sprayed aluminium profile coating represents the top level of surface treatment for architectural aluminium profiles. Its extremely long service life, very low maintenance cost and outstanding decorative effect make it highly cost-effective throughout the entire life cycle of the building, despite its relatively high initial cost. When making a choice, one should identify products that comply with the AAMA 2605 or GB/T 5237.5 standards, and pay attention to brand coatings (such as PPG, Akzonobel, KCC, etc.) and regular large-scale processing plants to ensure that their performanmce is truly implemented.

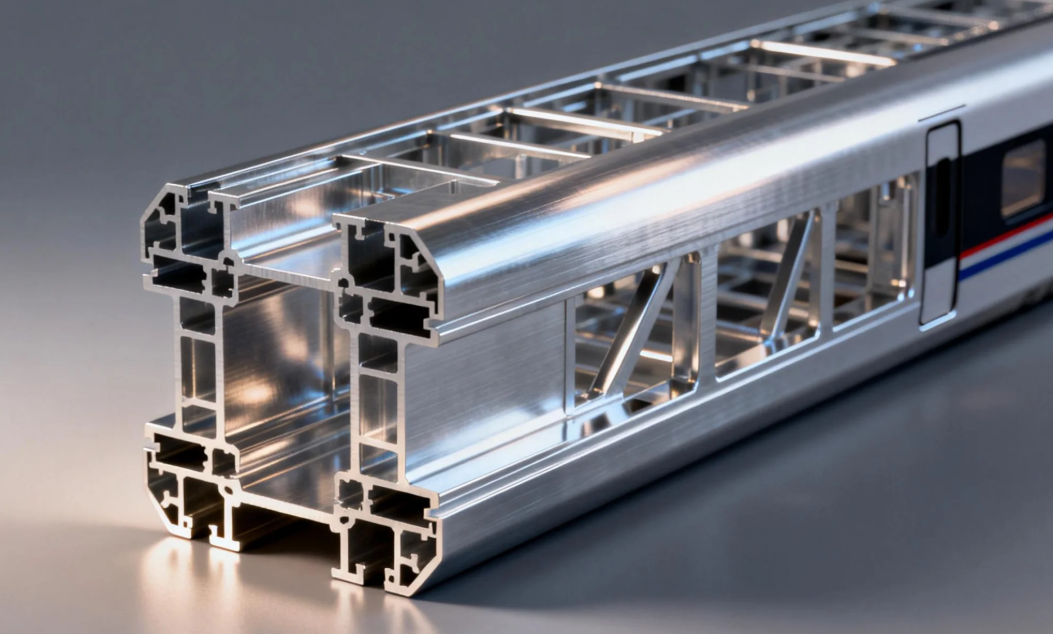

The advantages of using aluminium alloy for the main structure of high-speed train carriages

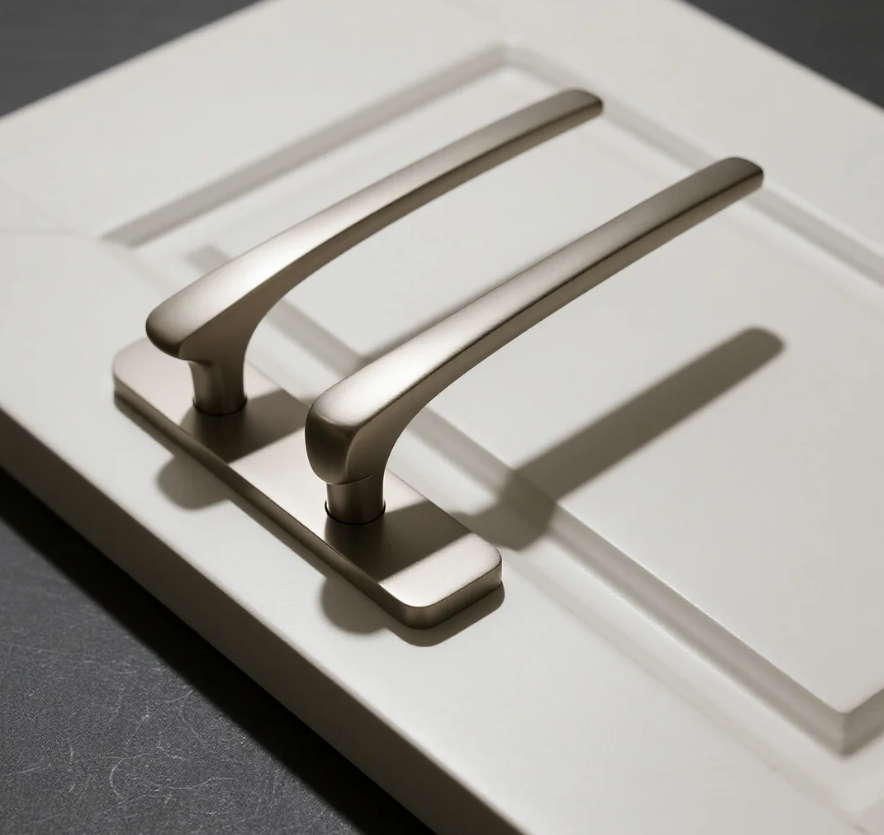

Methods for distinguishing Indoor and Outdoor Aluminium Doors

Maintenance methods and tips for aluminium doors and windows

Characteristic of outward-opening and hung aluminium windows

Xinhe Aluminium Research: 7.14-7.18 Analysis of Aluminium Prices

Seven Benefits Of Using Aluminium Profiles In Curtain Wall Systems

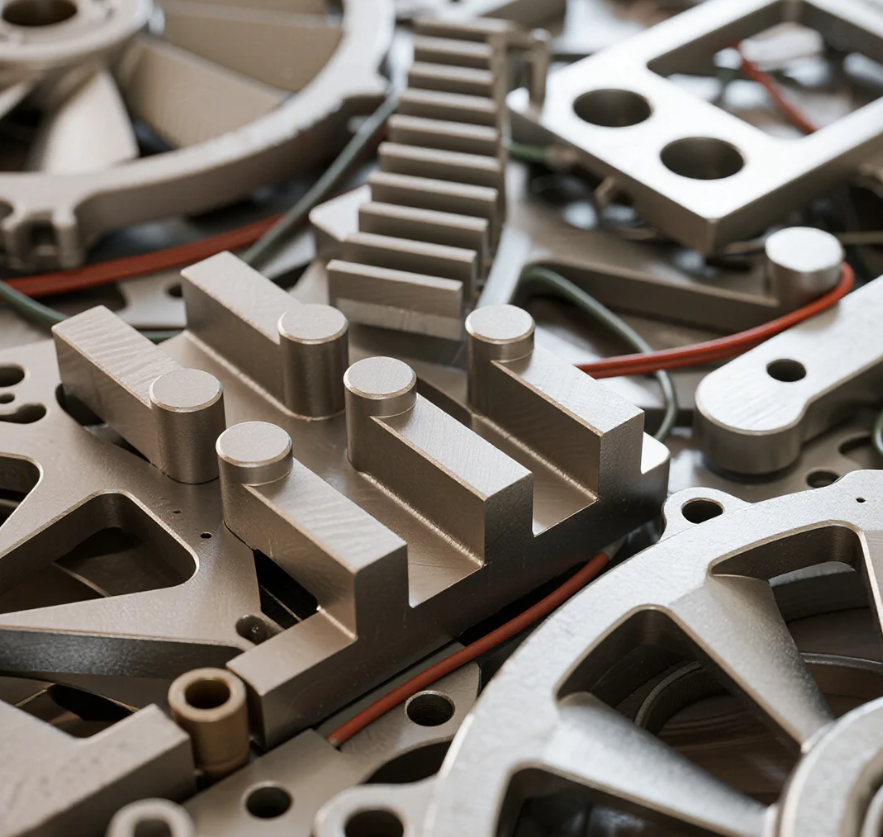

The Application of Aluminium Profiles in New Energy Vehicles

The Composition and Application of Series 6 Aluminium Alloys

Top 5 Benefits of Using LED Aluminium Profiles in Modern Lighting

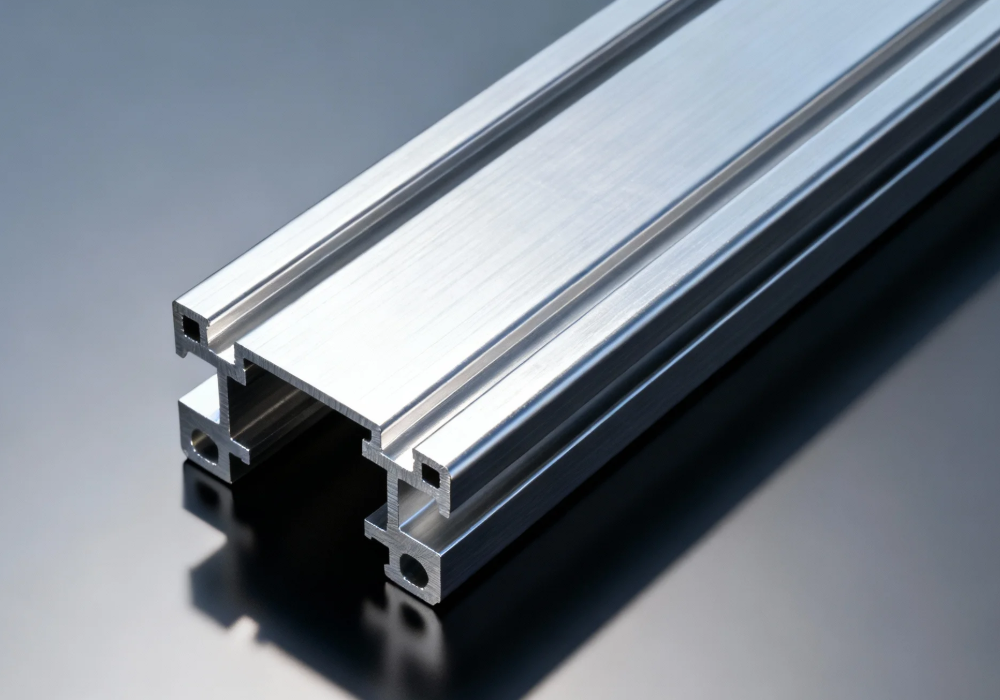

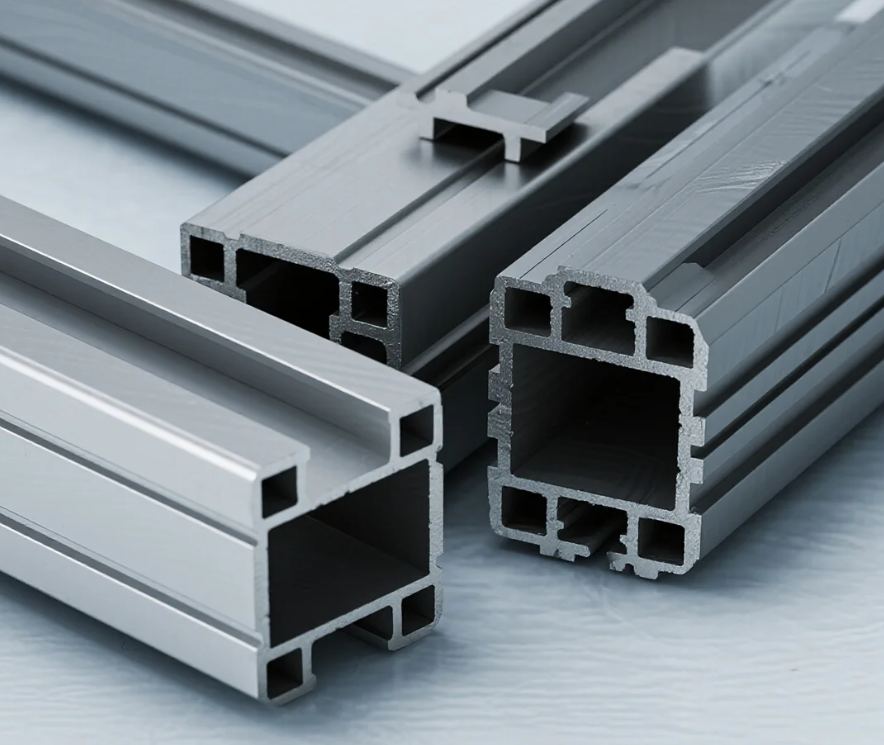

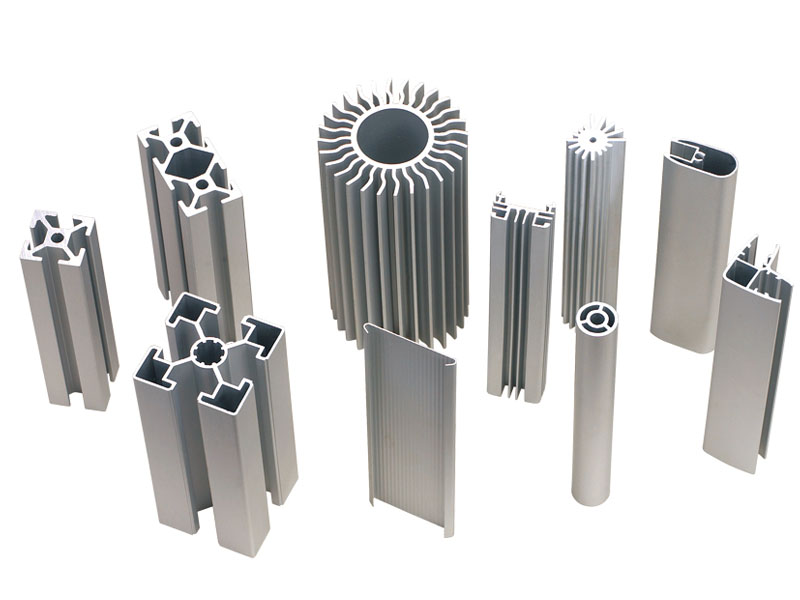

A Complete Guide to Aluminium Frame Profiles for Modern Structures

Exploring the Strength and Versatility of Aluminium Extrusion Profiles

How to Choose the Right Aluminium Profile Supplier for Your Project