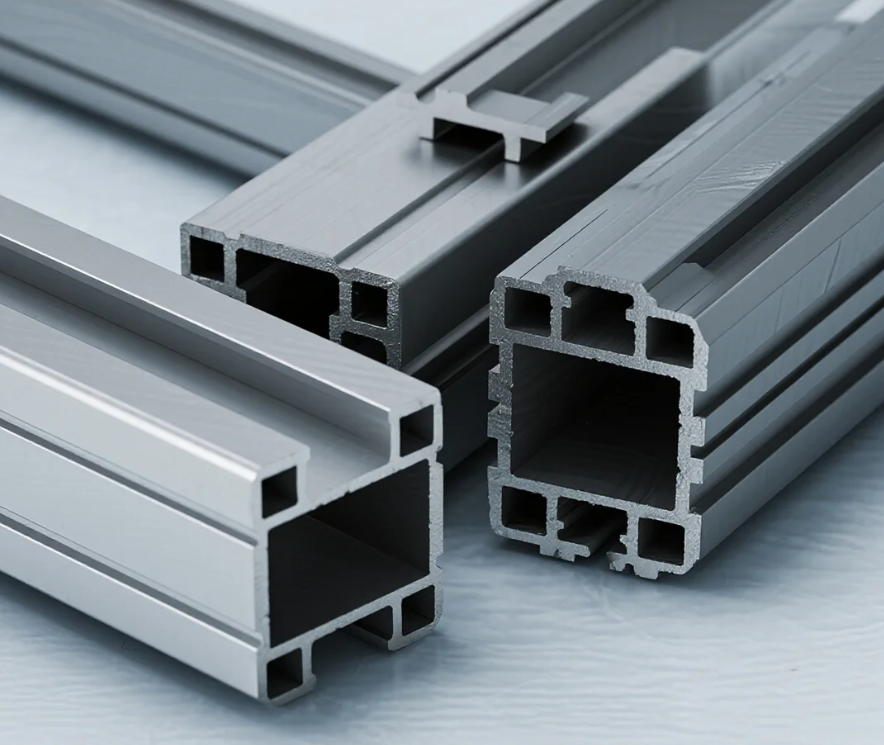

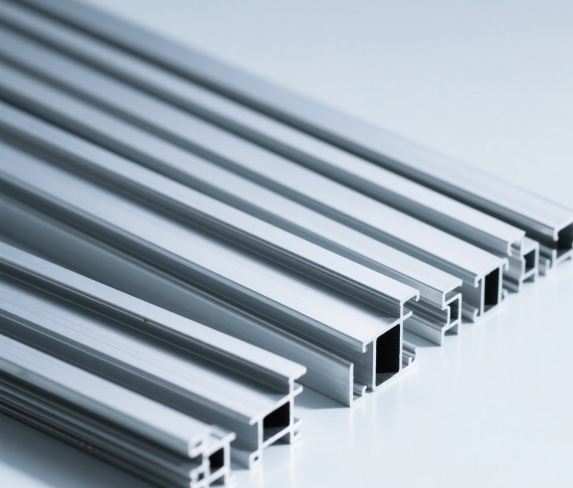

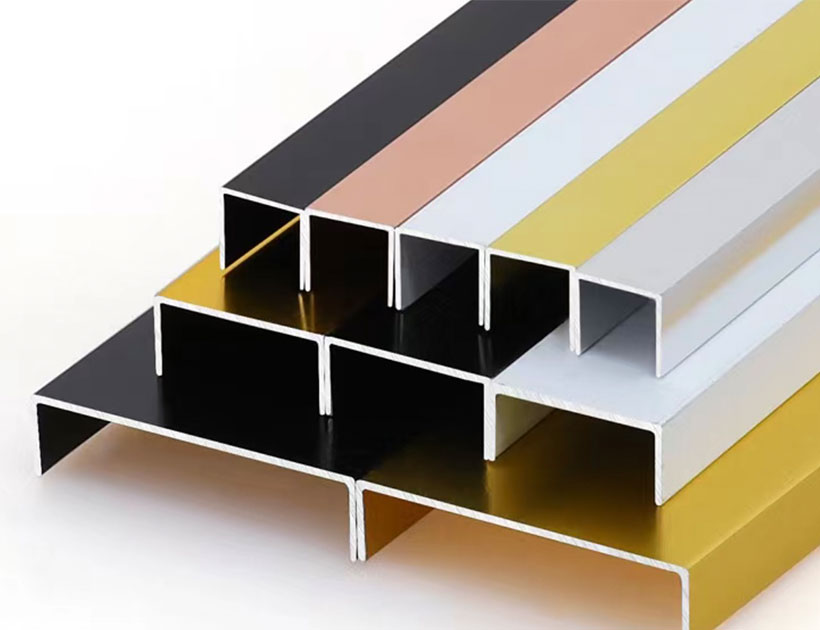

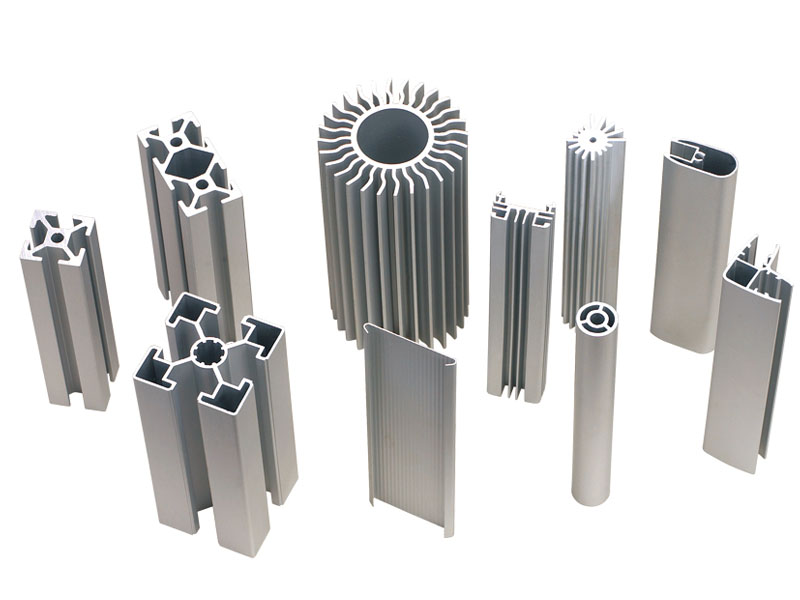

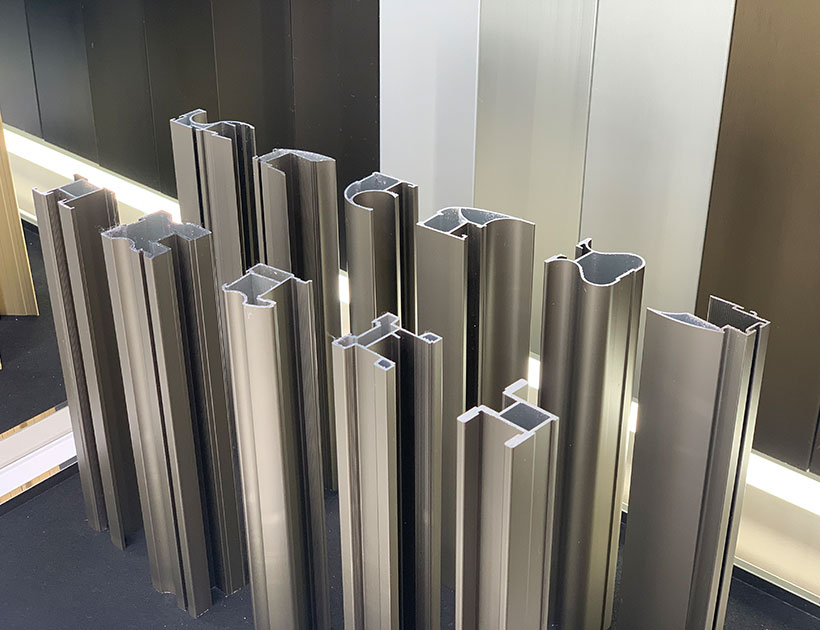

Aluminium profiles are widely used in various fields due to their advantages such as high strength, light weight, corrosion resistance, good appearance and easy processing. To maintain the best performance of aluminium profiles, extend their service life and keep them looking good, regular and correct maintenance and care are of vital importance. This manual will provide you with comprehensive guidance.

This is the most fundamental and crucial maintenance step, all aimed at removing daily dust and stains.

Cleaning frequency

1.1 Common environment: It is recommended to carry out a comprehensive cleaning every 3 to 6 months.

Harsh environment: Such as coastal areas (high salt content), industrial zones (high acid and alkali content, dust), and humid and rainy areas, it is recommended to increase the cleaning frequency, once every 1-2 months.

Special cases: After the rain, water stains on the surface of the profiles should be cleaned up in time, especially in areas with severe pollution.

1.2 Cleaning tools

1. Soft all-cotton fabric, sponge or soft brush.

2. Neutral detergents (such as diluted dishwashing liquid, special metal cleaners).

3. Al large amount of clean water (if conditions permit, deionized water works even better).

4. Soft rubber wiper (for cleaning glass and smooth surfaces).

1.3 Cleaning steps

Dust removal: First, use a feather duster or a soft-bristled brush to remove the floating dust and debris on the surface of the profile and in the grooves.

Rinsing: Rinse with a large amount of clean water to initially soften and wash away dirt that is not firmly adhered.

Cleaning: Dilute the neutral detergent in proportion, then use a soft cloth or sponge dipped in the solution to gently wipe the surface of the profile. Be sure to wipe along the texture direction of the profile.

Drying: Use a soft dry cotton cloth or rubber wiper to thoroughly dry the water marks on the surface of the profile to prevent the formation of scale.

1.4 Attention

The following types of cleaning agents and solvents are strictly prohibited

Strong acid and strong alkali cleaners: Such as hydrochloric acid, sulfuric acid, sodium hydroxide, etc., can severely corrode the surface of aluminium profiles and damage the oxide film or coating.

Abrasive cleaners: Such as scouring powder, wire balls, hard-bristled brushed, etc., can scratch the surface of profiles.

Irritating organic solvents: Such as thinner, turpentine, acetone, etc., can dissolve the coating on the surface of the profiles.

For stubborn stains that cannot be removed by regular cleaning, targeted measures should be taken.

| Type Of Stains | Method |

| Cement, mortar | Soften it with a damp cloth and then gently scrape it off with a wooden or plastic sheet. Never use metal tools. The remaining part can be wiped with a small amount of neutral detergent and a soft cloth. |

| Oily ink | Use a cotton cloth dipped in a small amount of alcohol or a special metal oil stain cleaner to gently wipe, and then immediately rinse thoroughly with clean water. |

| Residue of adhesive tape | Use a dedicated glue remover. After spraying, wait for a moment and then wipe with a soft cloth. Be sure to clean it thoroughly after completion. |

| Mold spots, dirt | It can be wiped with diluted ammonia water or neutral soap solution, and then rinsed with clean water. |

| Metal scratch | Minor scratches can be slightly ground and repaired with a special metal polishing paste. For anodized profiles, this method requires caution as it may alter the local color. |

| Processing principle | Try it in a small area at an inconspicuous place first, and then use it in a large area after confirming that there are no adverse reactions. After processing, be sure to rinse thoroughly and dry. |

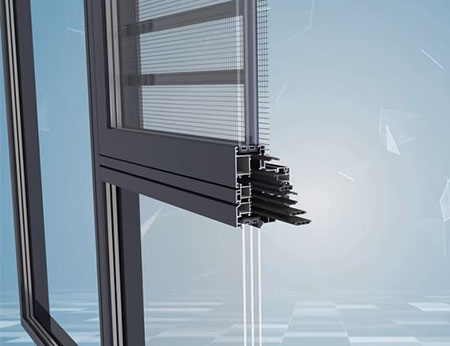

The normal operation of the aluminium profile system cannot do without the cooperation of hardware and sealing parts.

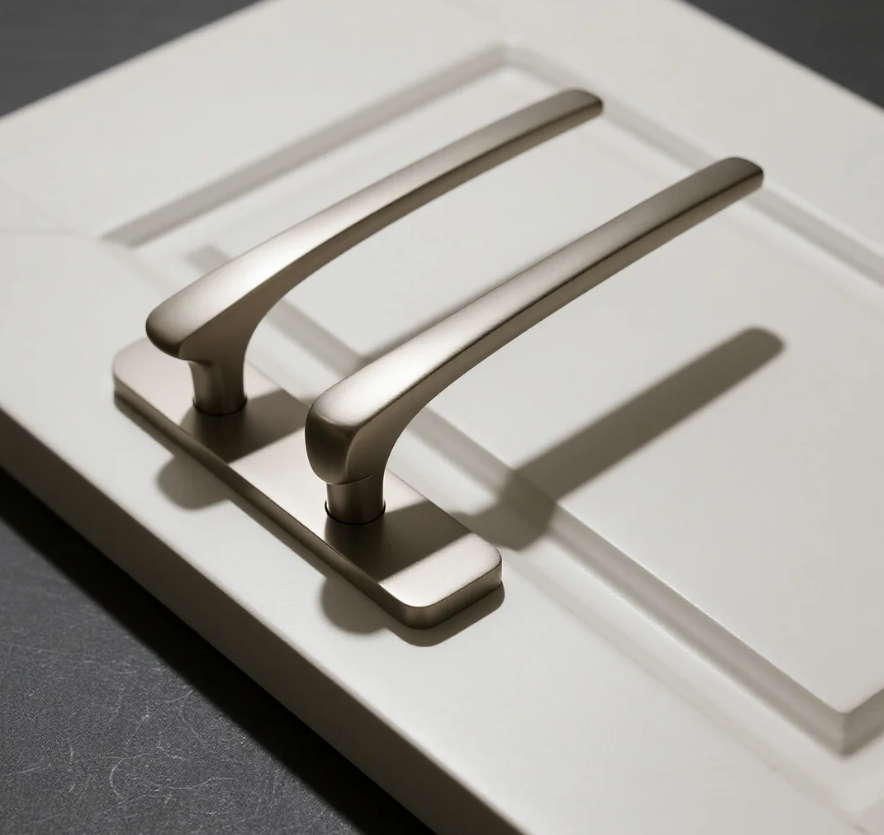

3.1 Hardware accessories (Hinges, lock points, handles, etc)

Regular inspection: Check if the screws are loose every six months. If any are found loose, tighten them immediately.

Lubrication: Regularly add a small amount of lubricating oil or grease to moving parts (such as hinges and actuators) to ensure smooth opening and closing. Note: Avoid grease from contaminating the surface of the profile.

Cleaning: Wipe the surface of the hardware such as the handle with a dry and soft cloth to avoid the long-term reside of water vapor and cleaning agents, and prevent damage to the surface coating.

3.2 Sealing system (sealing gasket)

Cleaning: When cleaning, wipe the sealing gasket strip at the same time to remove dust and maintain its elasticity.

Inspection: Regularly check whether the sealing gasket strips have any signs of cracking, aging, shrinkage or detachment.

Replacement: If it is found that the sealing gasket strip has lost its elasticity or is damaged, professional personnel should be contacted in time for replacement to ensure the sealing, sound insulation and heat preservation performance of the system.

In addition to daily cleaning, regular systematic inspections can promptly identify and solve problems.

Inspection cycle: It is recommended to conduct a comprehensive inspection at least once a year.

Inspection content: 1. Profile surface: Check whether the coating has any peeling, powdering, bubbling, discoloration or other conditions.

2.Connection parts: Check whether the screws, nails and other connecting parts are firm and free from corrosion.

3.Drainage system: Check whether the drainage holes of the door and window frames are blocked to ensure smooth drainage.

4.Drainage system: Check whether the drainage holes of the door.

The surface treatment methods of aluminium profiles vary, and so do the key point of maintenance.

Anodizing: Avoid long-term contact with alkaline substances such as cement and mortar; Avoid scratching with hard objects as the hardness of its oxide film is limited.

Electrophoretic coating: The maintenance method is similar to that of anodizing, but its weather resistance and scratch resistance are slightly better.

Powder coating: It has good corrosion resistance, but it is necessary to prevent the coating from peeling off due to impact from sharp objects.

PVDF: It has excellent weather resistance and self-ckeaning properties, and is the easiest to maintain. Usually, it only requires rainwater flushing or regular cleaning.

When conducting high-altitude operations (such as cleaning curtain walls and high Windows), adequate safety measures must be taken, such as using safety belts and safety platforms. It is best to entrust a professional company to carry out the work.

Before using any chemical cleaner, be sure to read the product instructions and test it in a concealed place.

If severe corrosion, structural loosening or deformation and other major problems are found in the profiles, their use should be immediately stopped and professional personnel should be contacted for maintenance.

Proper maintenance and care are the key to ensuring the long-term stable use and aesthetic appearance of aluminum profiles. By following the guidance in this manual, you can maximize the lifespan of your aluminum profile products and ensure they are always in the best condition.

Note: The content of this manual is for reference only. For specific operations, please refer to the actual situation of the product.

Methods for distinguishing Indoor and Outdoor Aluminium Doors

Maintenance methods and tips for aluminium doors and windows

Characteristic of outward-opening and hung aluminium windows

Xinhe Aluminium Research: 7.14-7.18 Analysis of Aluminium Prices

Seven Benefits Of Using Aluminium Profiles In Curtain Wall Systems

The Application of Aluminium Profiles in New Energy Vehicles

The Composition and Application of Series 6 Aluminium Alloys

Top 5 Benefits of Using LED Aluminium Profiles in Modern Lighting

A Complete Guide to Aluminium Frame Profiles for Modern Structures

Exploring the Strength and Versatility of Aluminium Extrusion Profiles

How to Choose the Right Aluminium Profile Supplier for Your Project