Patents

Products

Annual Output

Countries

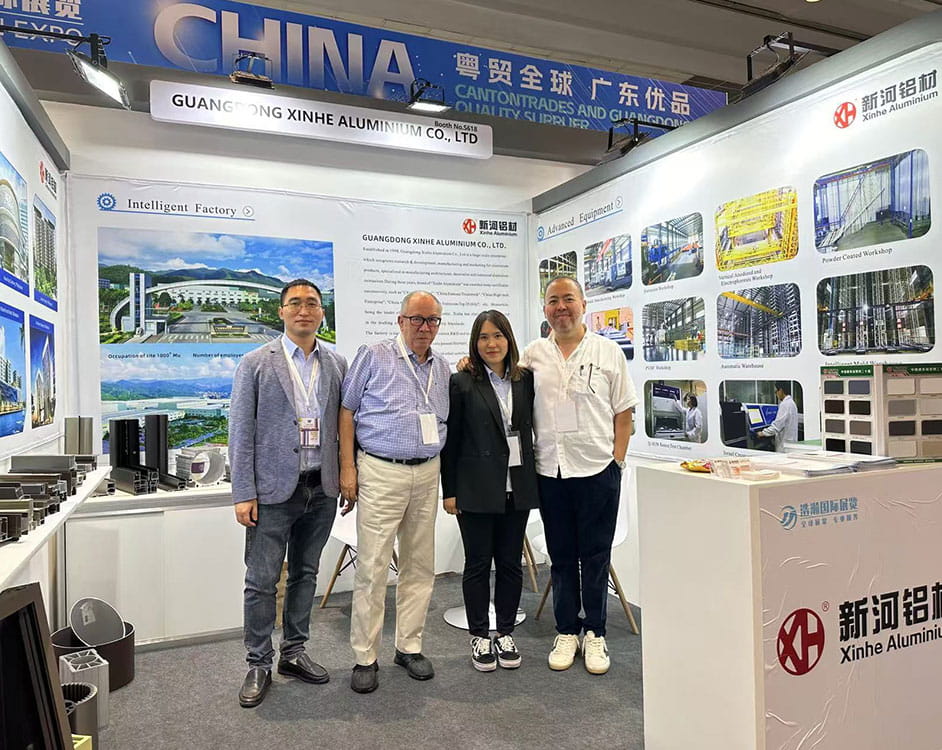

Xinhe Aluminium has an aluminium profile factory covering an area of more than 600,000 square meters in Xincheng Industrial Park, Xinxing District, Yunfu City, Guangdong Province. The factory is equipped with advanced vertical anodizing and electrophoresis production lines, vertical powder coating production lines, 5,000-ton aluminium extruders, automatic vertical warehousing equipment, etc.

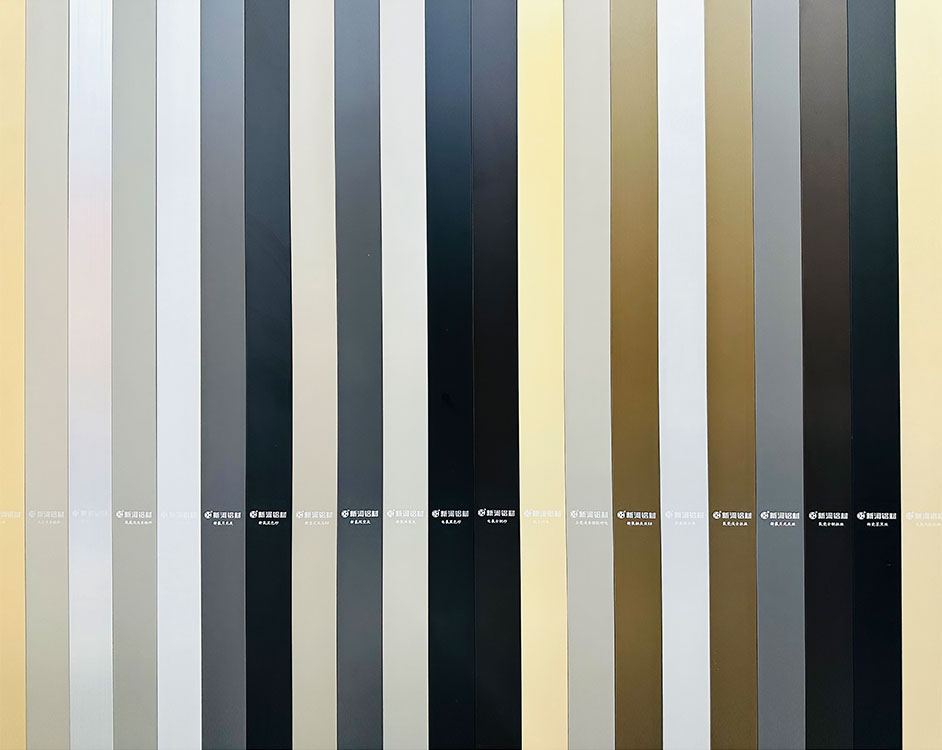

At present, we have established a complete aluminium extrusion production system, including casting, extrusion, anodizing, electrophoresis, powder coating, PVDF, thermal transfer wood grain, polishing, brushing, thermal insulation (insulated rubber and glue injection), window and door fabrication, industrial extrusion finish machining, automated logistics system, etc., while enriching the product variety, it also meets different production needs.

The raw materials are formed into aluminium rods of the required alloy grade through casting.

The moulds are manufactured using a production line that mainly uses automated and intelligent aluminum extrusion machining equipment.

Under high pressure, it is extruded through a die to form an aluminium profile with the required cross-sectional shape.

Improve the extrusion performance and hardness of aluminium profiles through heat treatment.

Through surface treatment technology, the wear resistance, corrosion resistance, weather resistance and decorative effect of aluminium profiles can be improved.

After deep machining, aluminium profiles are made into doors, windows and other aluminum products, and then undergo assembly, testing and other steps.

We will use vertical aluminium profile intelligent warehouses to store and manage aluminium products to improve space utilization.

Ready to learn more? Fill out the form and a member of our dedicated team will reach out to you promptly!

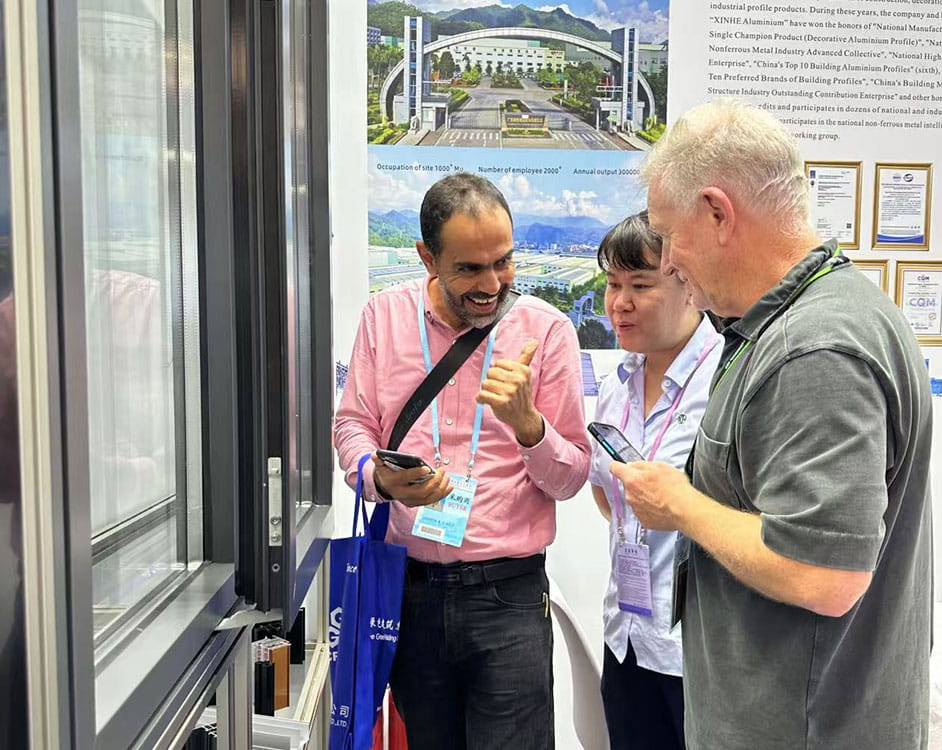

Xinhe Aluminium actively participates in the construction of the “Belt and Road” project. Our aluminium profiles, aluminium doors and windows, aluminium curtain walls, etc. have been widely used around the world.